obj

min

Minimum object angle [°]

α

spot

Beam spot size [°], here 0.3°

α

meas

Measuring interval [°], see table 5, page 30

α

res

Angular resolution [°], horizontal 0.125°, vertical 0°

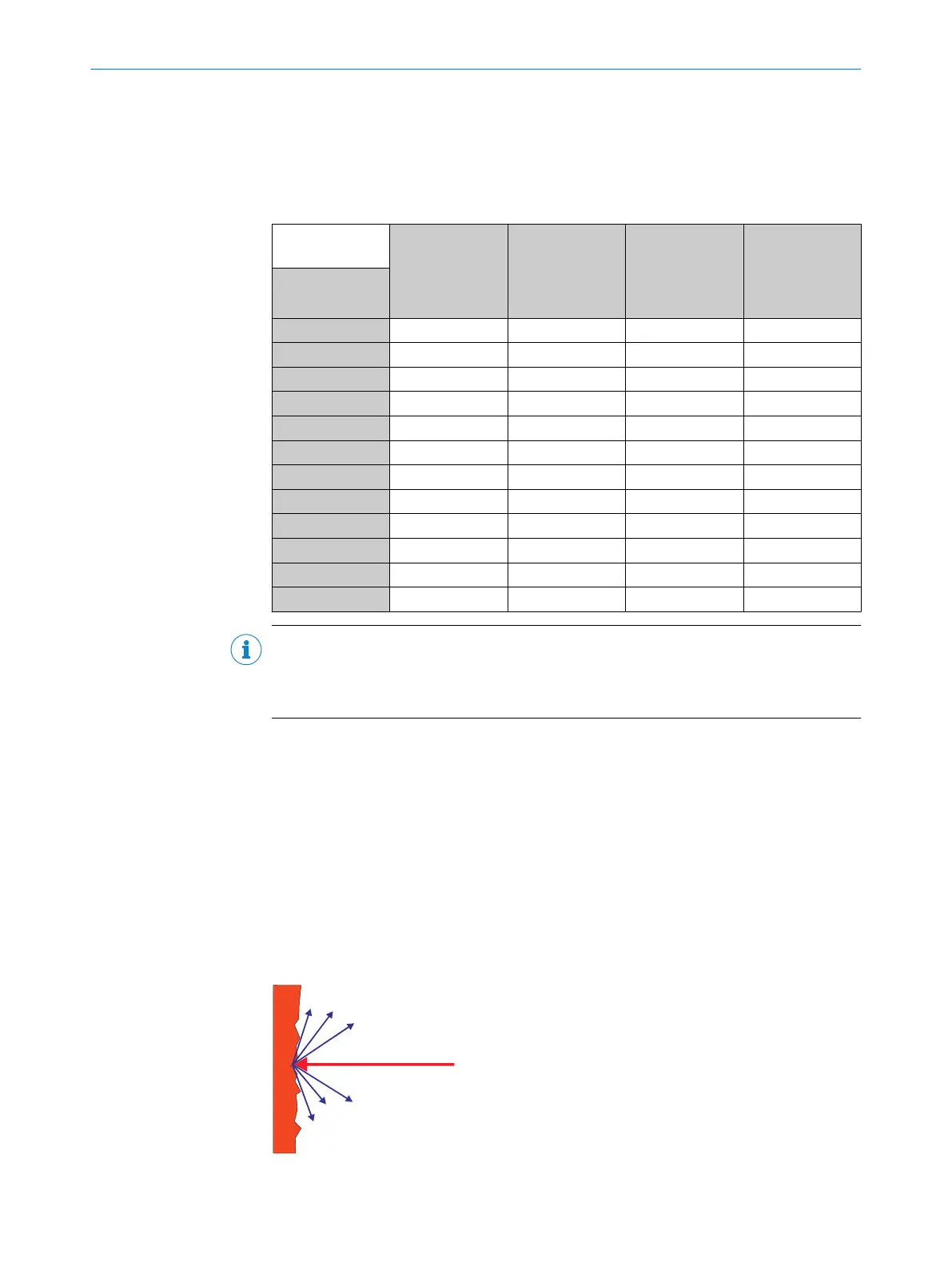

Table 5: Typical minimum object size [mm] as a function of distance and angular resolution

Angular resolu‐

tion [α

res

]

Horizontal

0.125°

(red high-resolu‐

tion scan layer

see figure 24 )

Horizontal 1.0°

(orange scan

layer see

figure 24)

Vertical 2.5°

(between red and

orange scan layer

see figure 24)

Vertical 5.0°

(between two

orange scan lay‐

ers see figure 24)

Distance [mm]

100 13 13 13 13

200 13 13 13 19

500 13 13 26 47

1000 13 25 51 95

2000 19 50 102 190

3000 29 75 153 285

5000 48 124 255 475

10000 96 249 511 950

15000 144 373 766 1425

20000 192 498 1022 1899

25000 240 622 1277 2374

30000 288 746 1533 2849

NOTE

For reliable measurement, in particular when using the device to output measured val‐

ues, the laser needs to hit the object with multiple beams. An object should therefore

be larger than the minimum object size.

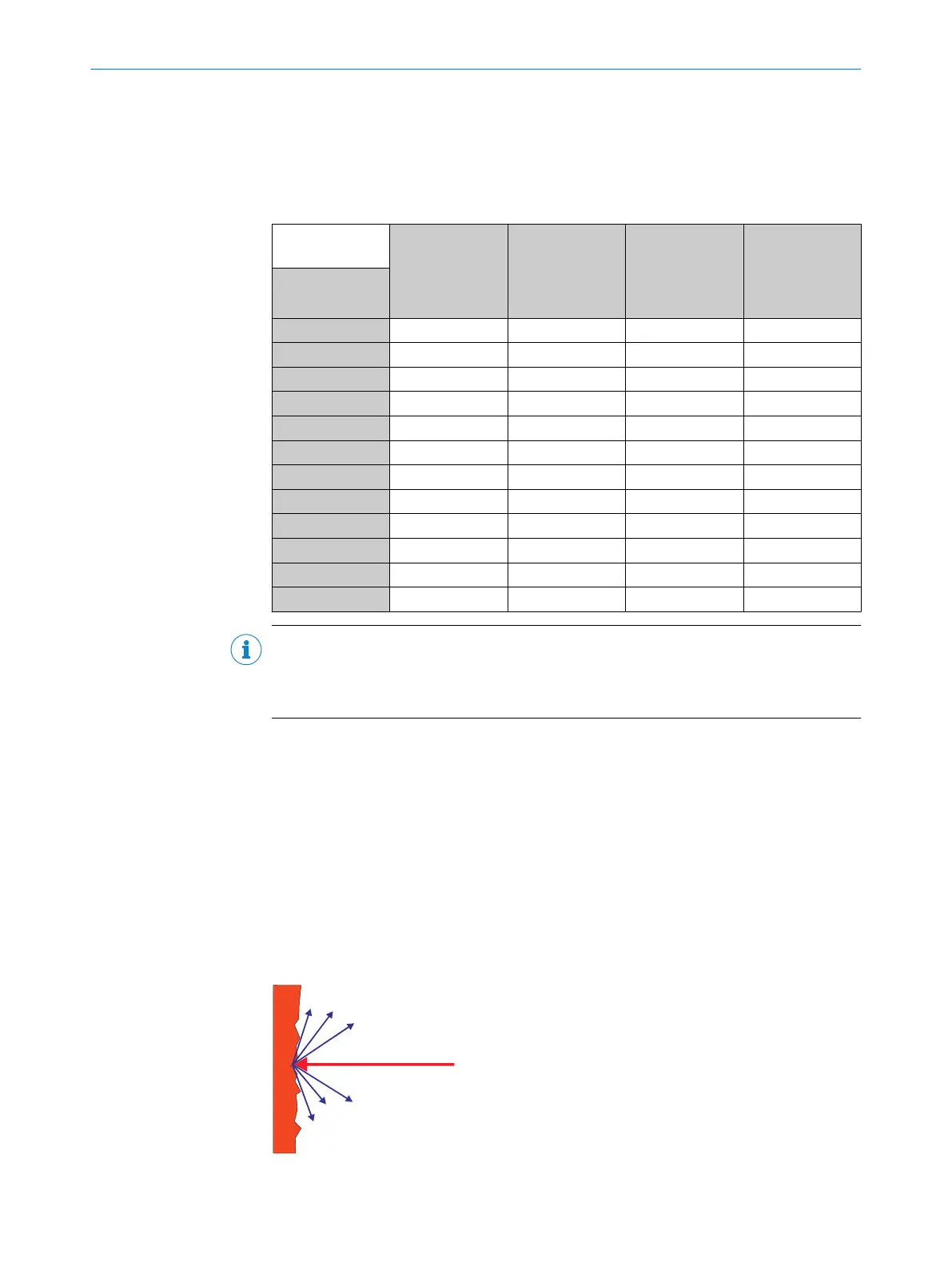

3.4.10 Impact of object surfaces on the measurement

Reflection

Most surfaces produce a diffuse reflection of the laser beam in all directions. The

structure (smooth or rough), shape (flat or curved), and color (light or dark) of the

surface determine how well the laser beam is reflected.

On very rough surfaces, a large proportion of the energy is lost due to absorption.

Curved surfaces produce a higher diffusion. Dark surfaces reflect the laser beam worse

than light ones (brilliant white plaster reflects approx. 100% of the light, while black

foam rubber reflects approx. 2.4%). The aforementioned surface characteristics can

reduce the scanning range of the device, in particular for surfaces with low remission

values.

Figure 25: Reflection of light on the surface of the object

3 PRODUCT DESCRIPTION

30

O P E R A T I N G I N S T R U C T I O N S | multiScan136 8027119/0000/2022-11 | SICK

Subject to change without notice

Loading...

Loading...