7 Programming FCs (Functions) and FBs for S7 Ethernet CPs

A-245

S7-CPs for Industrial Ethernet Configuring and Commissioning

Release 01/2007

C79000-G8976-C182-07

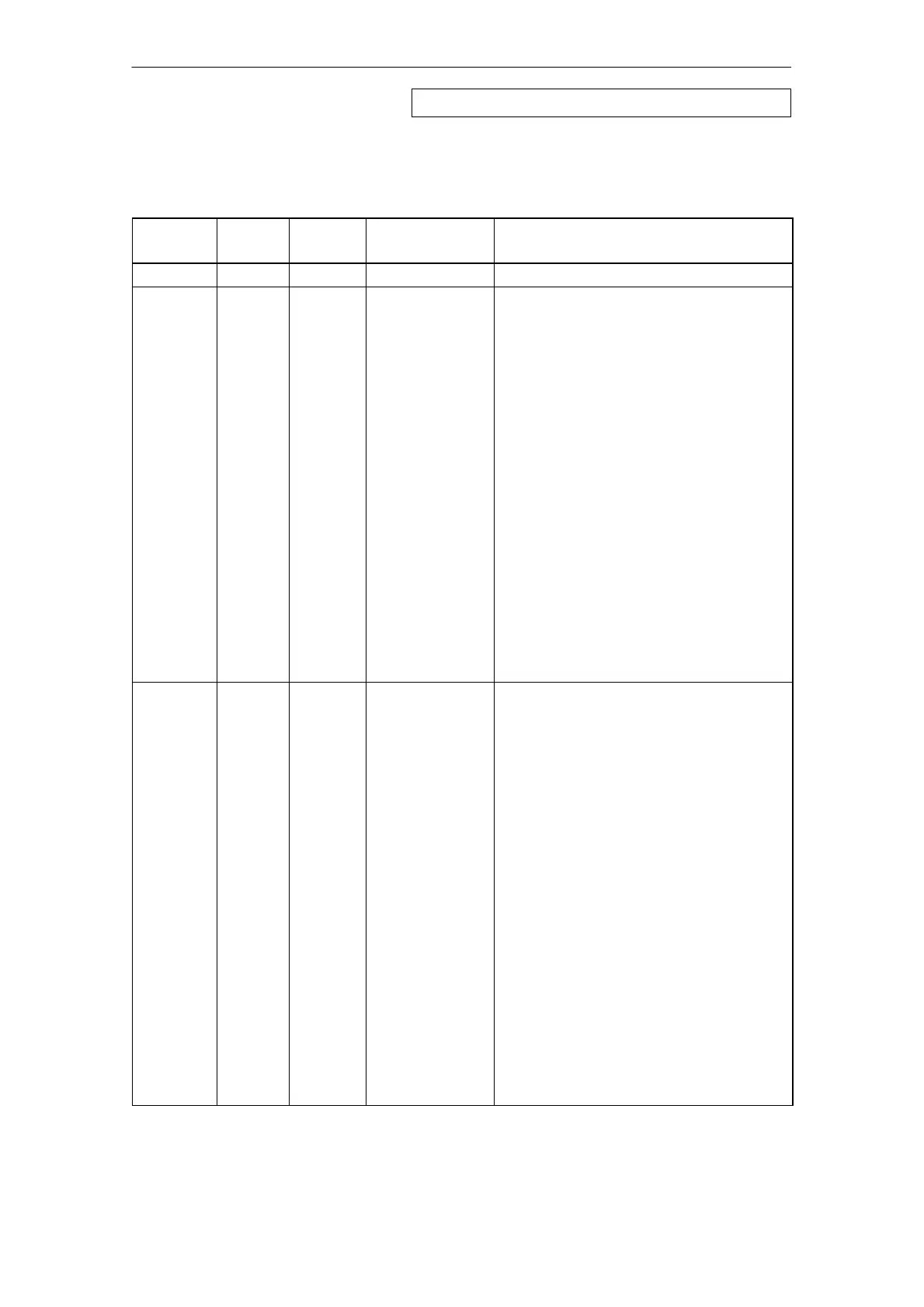

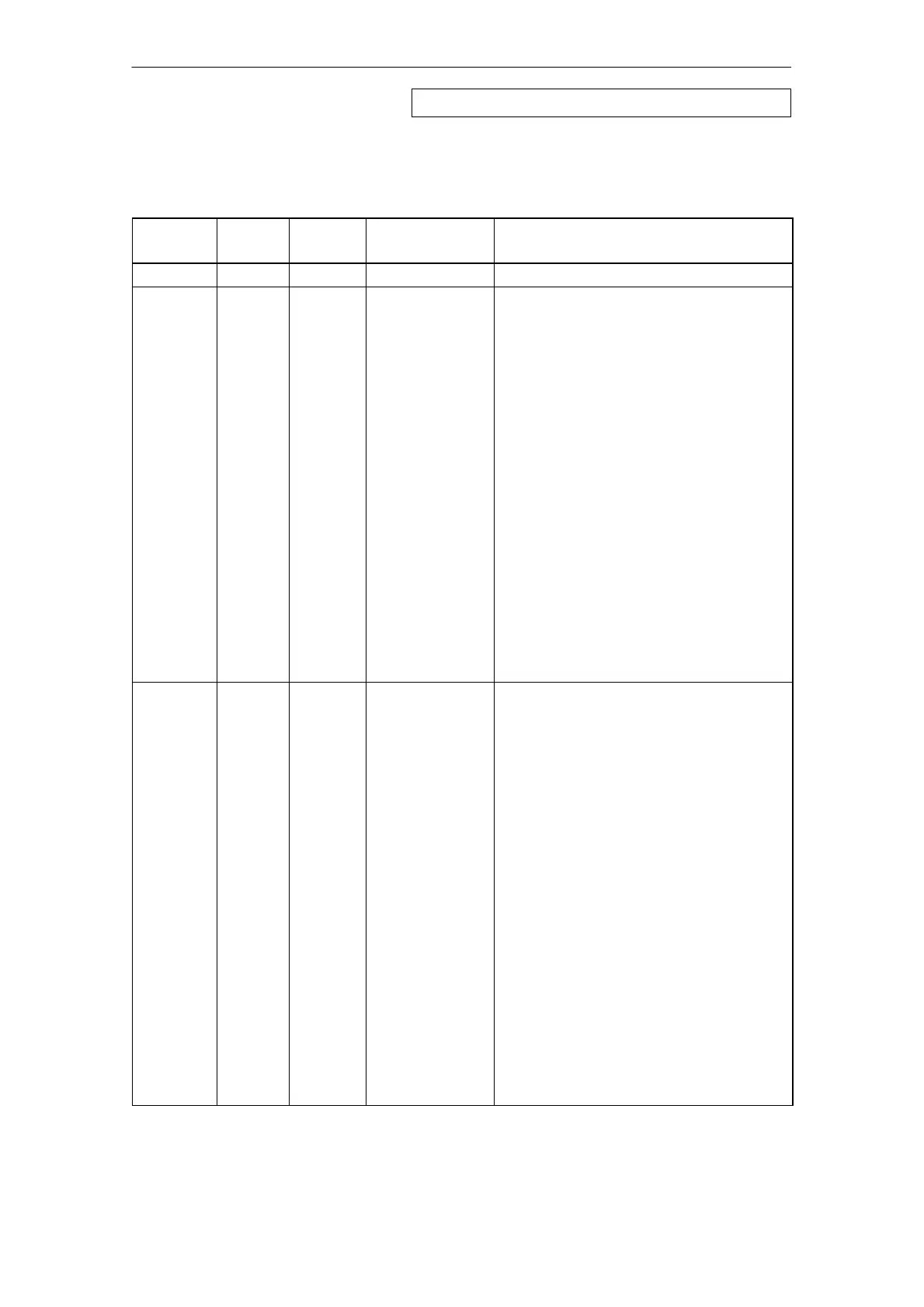

Explanation of the Formal Parameters

The following table explains all the formal parameters for FC12:

Paramete

r

Declara

tion

Type Possible

Values

Remarks

CPLADDR INPUT WORD - Module base address

RECV IN_OUT ANY (as

VARTYPE

only

BYTE is

permitted)

The address of

the data area

points to one of

the alternatives:

Memory bit

area

Data block

area

Specifies the address and length.

Controller mode:

The length should match the total length of the

distributed IO configured in HW Config,

whereby address gaps are also transmitted.

Device mode:

The data structure results from the order of

the slots of the output modules configured for

this PROFINET IO device on the PROFINET

IO controller line and their length without

address gaps.

Notes:

The block begins to transfer the data at

address 0 regardless of how you

configured the addresses (regardless of

the lowest configured address).

Specifying an I/O area is not permitted

since you must first change the IOPS for

GOOD before data can be accepted in the

I/O.

LEN INPUT INT Value > 0

The maximum

total length of the

data to be

transferred can be

found in the

device-specific

Part B of this

manual in the

“Performance

Data” chapter.

They may differ

for controller or

device mode.

Length of the data area to be transferred in

bytes.

The transfer of the data always begins with

address 0 regardless of the configuration.

Please note that the IO address “0” with a

length of 1 is included.

Controller mode:

The highest configured address of the

devices must be specified here. The

individual areas are not grouped together.

The data is transferred in the order of the

logical addresses (as with PROFIBUS

DP).

Device mode:

The data is transferred in the order of the

slots corresponding to the configuration of

the input modules on the PROFINET IO

controller line for this PROFINET IO

device.

Note

Make sure that the length programmed

here and the configuration of the

PROFINET IO controller are consistent.

FC 12 PNIO_RECV - continued

Loading...

Loading...