Configuration

5.3 Dimensioning

Synchronous Motors 1FK7

Configuration Manual, (PFK7S), Edition 12.2006, 6SN1197-0AD16-0BP1

63

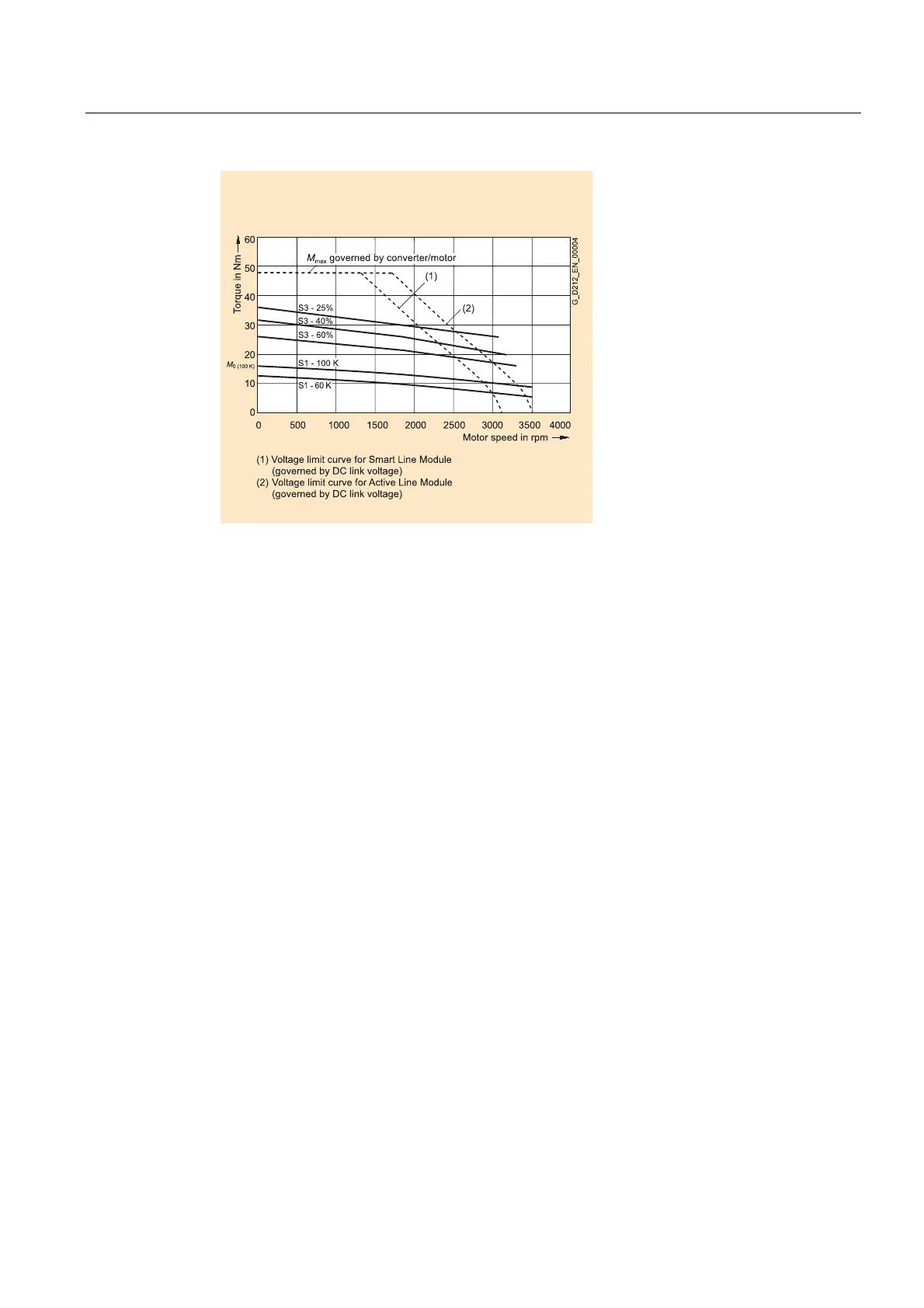

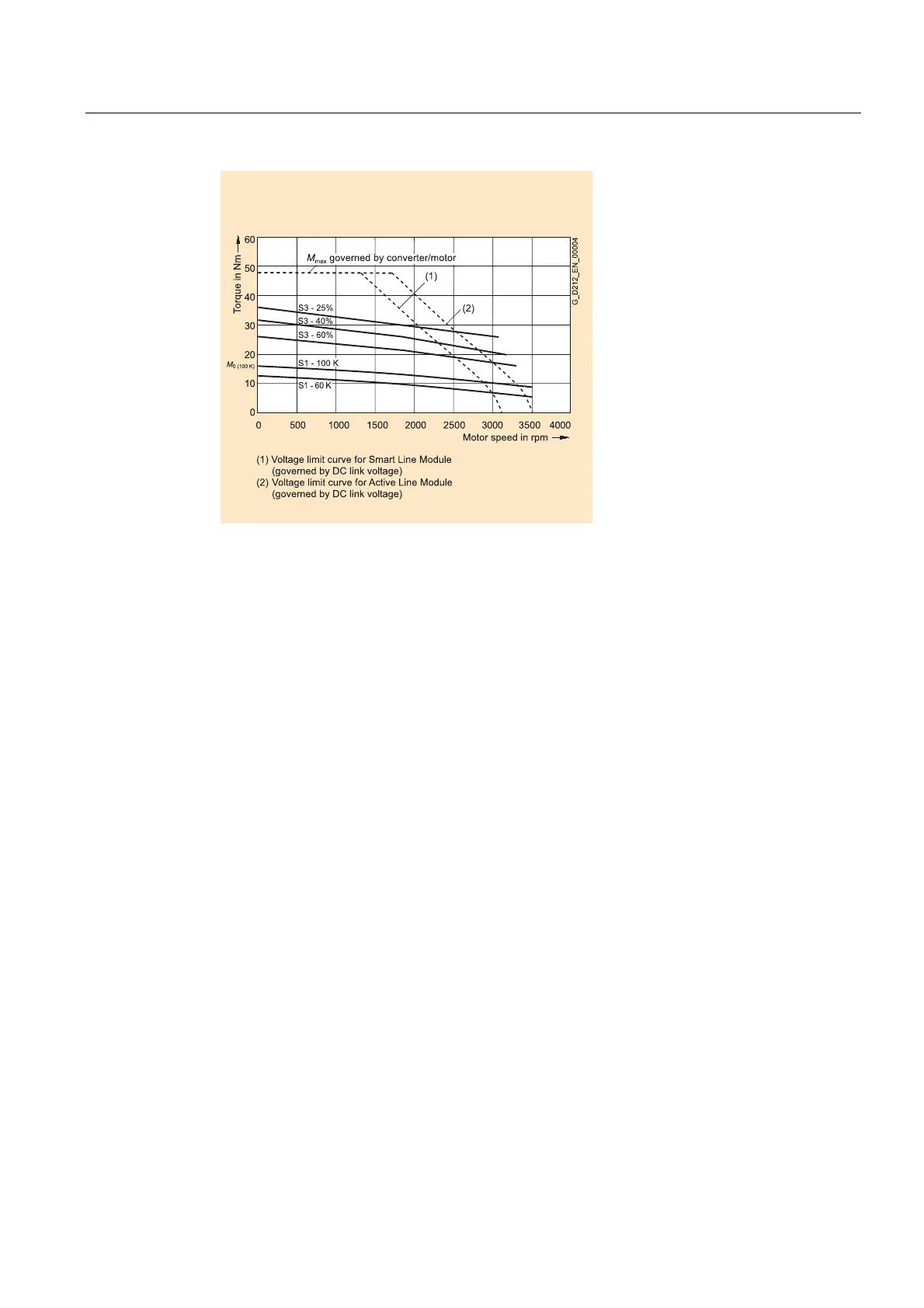

Figure 5-4 Limit curves for synchronous motors

5.3.2 2. Definition of the load event, calculation of max. load torque

Load duty cycles

The motor is selected based on the load which is specified by the application. Different

characteristic curves must be used for different load events.

The following operating scenarios have been defined:

• Load duty cycle with constant ON period

• Load duty cycles with varying ON period

• Free duty cycle

The objective is to identify characteristic torque and speed operating points, on the basis of

which the motor can be selected depending on the particular load.

Once the operating scenario has been defined and specified, the maximum motor torque is

calculated. Generally, the maximum motor torque is required when accelerating. The load

torque and the torque required to accelerate the motor are added.

The maximum motor torque is then verified with the limiting characteristic curves of

the motors.

The following criteria must be taken into account when selecting the motor:

• The dynamic limits must be adhered to, i.e., all speed-torque points of the relevant load

event must lie below the relevant limiting characteristic curve.

• The thermal limits must be adhered to, i.e. for synchronous motors, the RMS motor

torque at the average motor speed resulting from the duty cycle must lie below the

S1 characteristic curve (continuous duty). For induction motors, the RMS value of

the motor current within a duty cycle must be less than the rated motor current.

Loading...

Loading...