Start-Up

4.3 Starting up the PLC

4-59

SINUMERIK 802C

6FC5 597–3AA20–0BP2 (01.02)

The control system is able store max. 4,000 instructions and 1,000 symbols. The required PLC

memory is influenced by the following components:

S Number of instructions

S Number and length of the symbol names

S Number and length of the comments

S7–200 ladder diagram

A ladder diagram is a graphical programming language similar to electric circuit diagrams.

When creating a program using the ladder diagram form, then you will work with graphical

components to create the networks of your logics. To create your program, you can use the

following elements:

S Contacts constitute a switch through which the current can flow. Current, however, will only

flow through a normally open contact if the contact is closed (logical

value 1). Current will flow through a normally closed contact or a negated contact (NOT) if

the contact is open (logical value 0).

S Coils constitute a relay or an output which is updated by the signal flow.

S Boxes constitute a function (e.g. a timer, counter or arithmetic operation) which is carried

out at the moment when the signal flow reaches the box.

A network consists of the elements mentioned above, forming a closed circuit. The current

flows from the left conductor bar (in the ladder diagram symbolized by a vertical line at the left

window) through the closed contacts, enabling coils or boxes.

Overview of commands

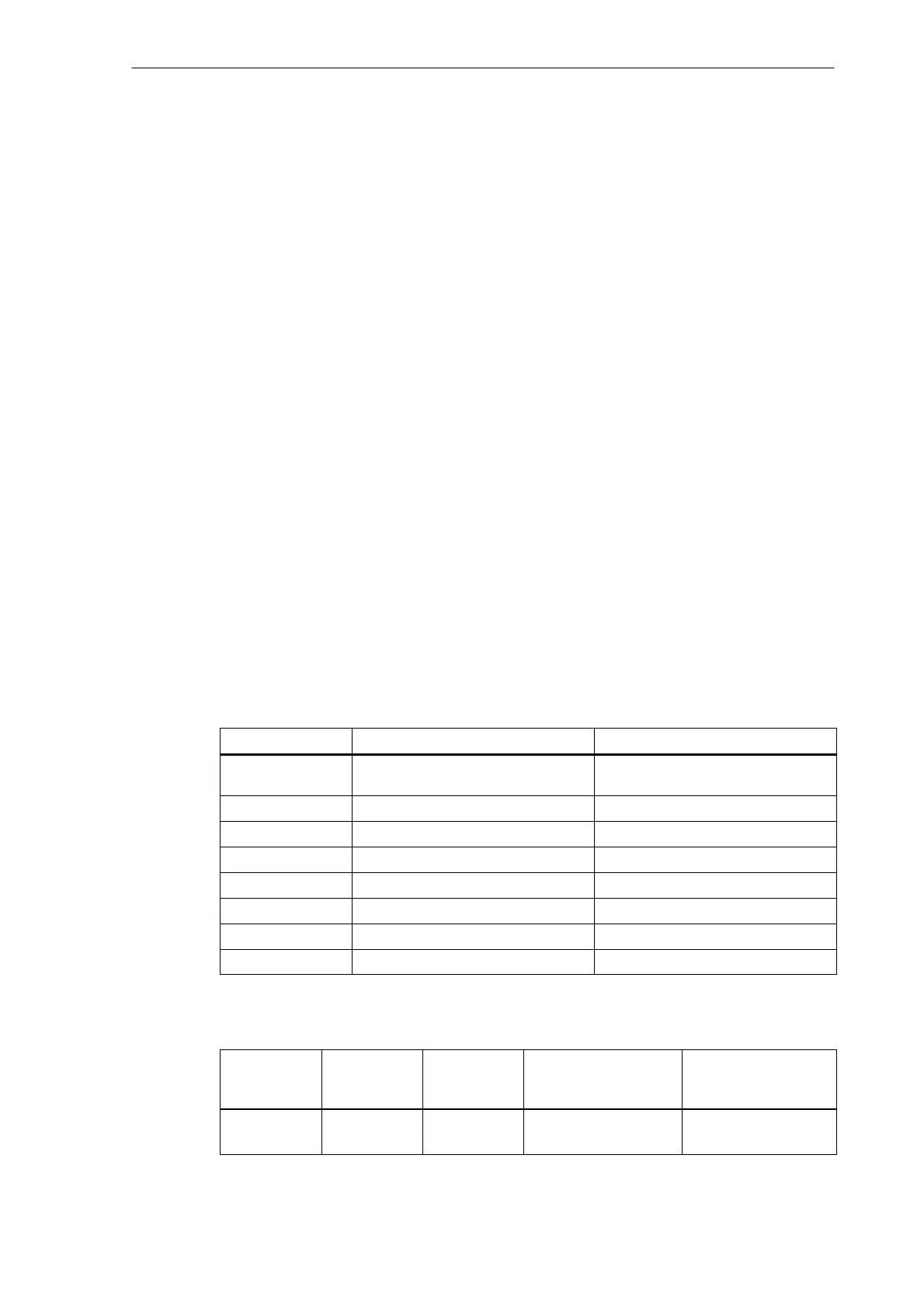

Table 4-7 Operand identifers

Operand ID

Description Range

V Data V0.0 to V79999999.7 (see Table

4–8)

T Timers T0 to T15

C Counters C0 to C31

I Map of digital inputs I0.0 to I7.7

Q Map of digital outputs Q0.0 to Q7.7

M Flags M0.0 to M127.7

SM Special flags SM0.0 to SM 0.6 (see Table 4–10)

AC ACCU AC0 ... AC3

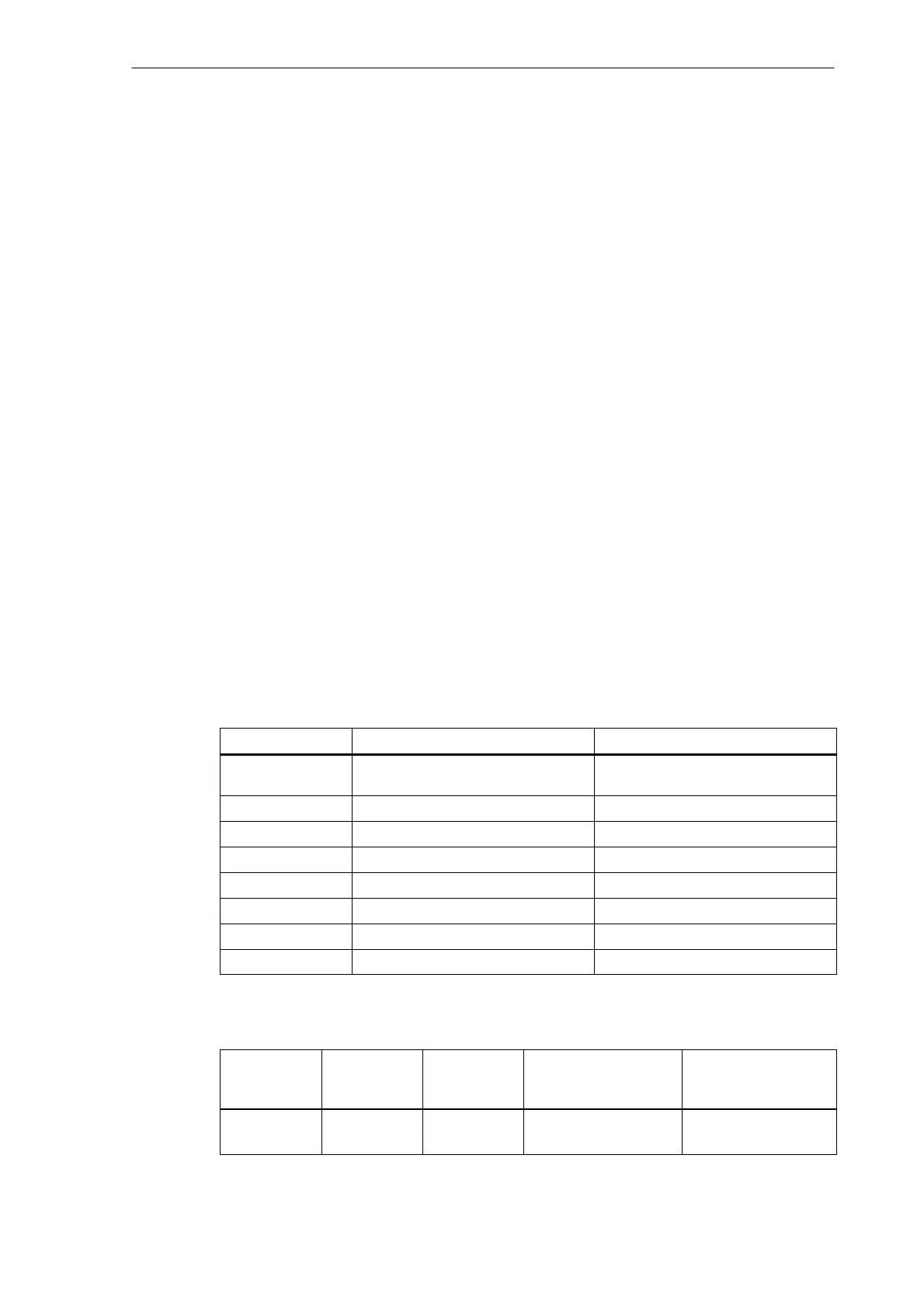

Table 4-8 Generating the addresses for the V range (see user interface)

Type Code

(DB No.)

Range No.

(Channel/

Axis No.)

Subrange Offset Addressing

00

(00–79)

00

(00–99)

0

(0–9)

000

(000–999)

symbolic

(8–digit)

Loading...

Loading...