Detailed description

2.12 Block descriptions

Power Line Basic PLC Program (P3)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-197

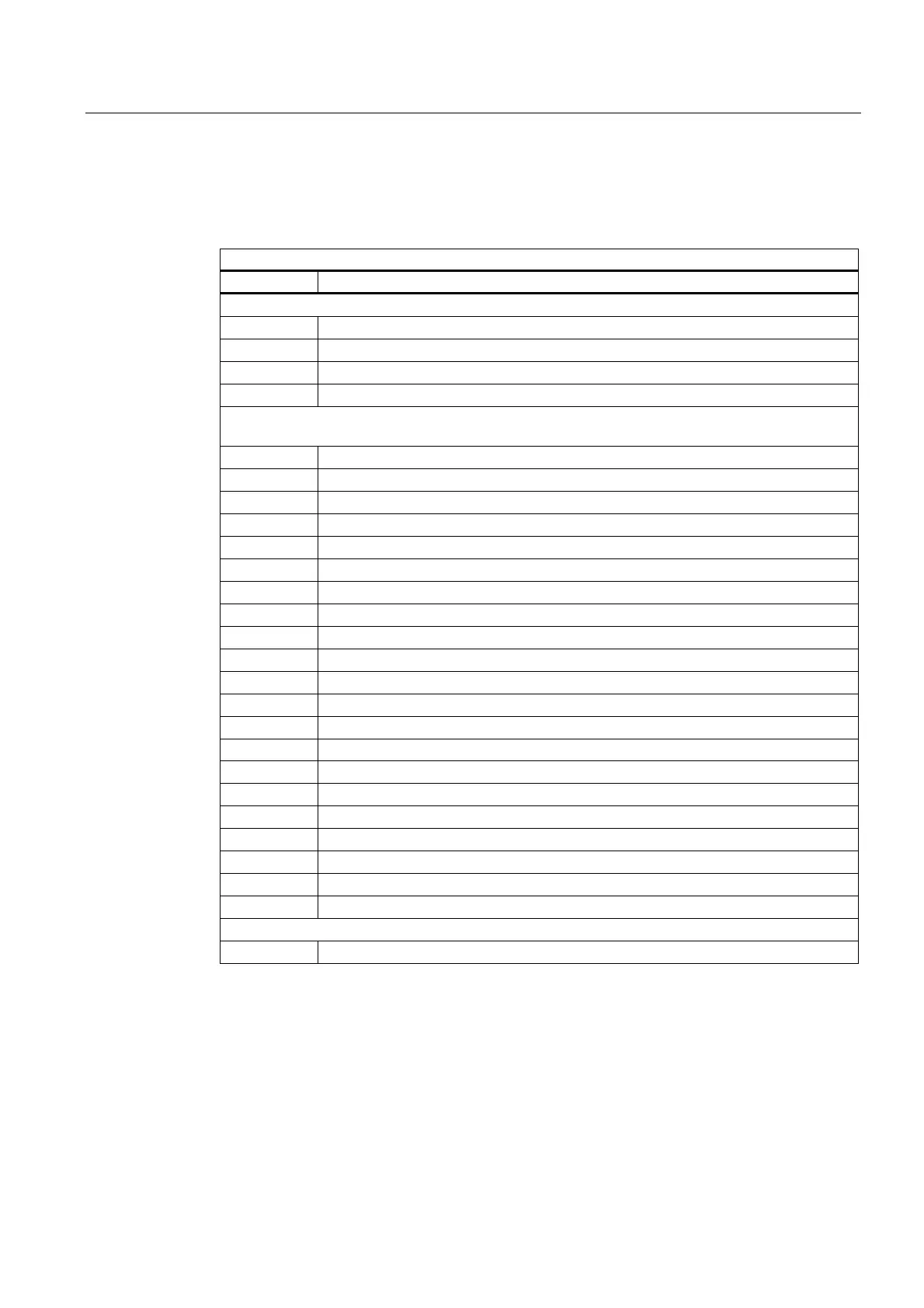

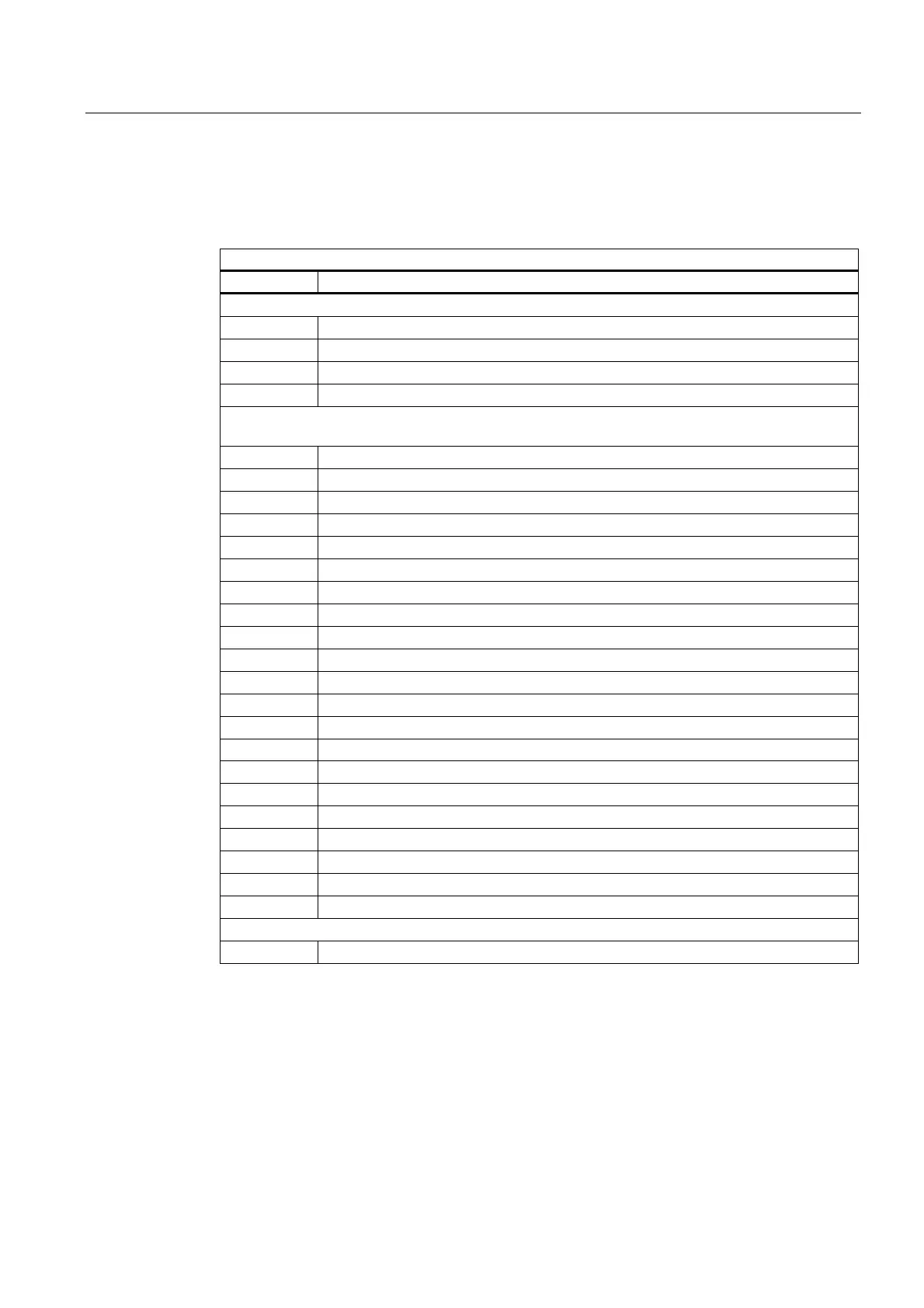

Error identifiers

Error identifiers

State Meaning

Errors caused by PLC handling

1 Several axis/spindle functions have been activated simultaneously

20 A function has been started without the position being reached

30 The axis/spindle has been transferred to the NC while still in motion

40 The axis is programmed in the NC program

Errors which occur during NCK routines.

The alarm numbers are described in the 840D Diagnostics Guide

100 Corresponds to alarm no.: 16830

105 Corresponds to alarm no.: 16770

106 Corresponds to alarm no.: 22052

107 Corresponds to alarm no.: 22051

108 Corresponds to alarm no.: 22050

109 Corresponds to alarm no.: 22055

110 Velocity/speed is negative

111 Setpoint speed is zero

112 Invalid gear stage

115 Programmed position has not been reached

117 G96/G961 is not active in the NC

118 G96/G961 is still active in the NC

120 Not an indexing axis

121 Indexing position error

125 DC (shortest path) not possible

126 Minus absolute value not possible

127 Plus absolute value not possible

130 Software limit switch plus

131 Software limit switch minus

132 Working area limitation plus

133 Working area limitation minus

System or other serious alarms

200 Corresponds to system alarm no.: 450007

Loading...

Loading...