Detailed Description

2.4 Referencing with incremental measurement systems

Reference Point Approach (R1)

2-8 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

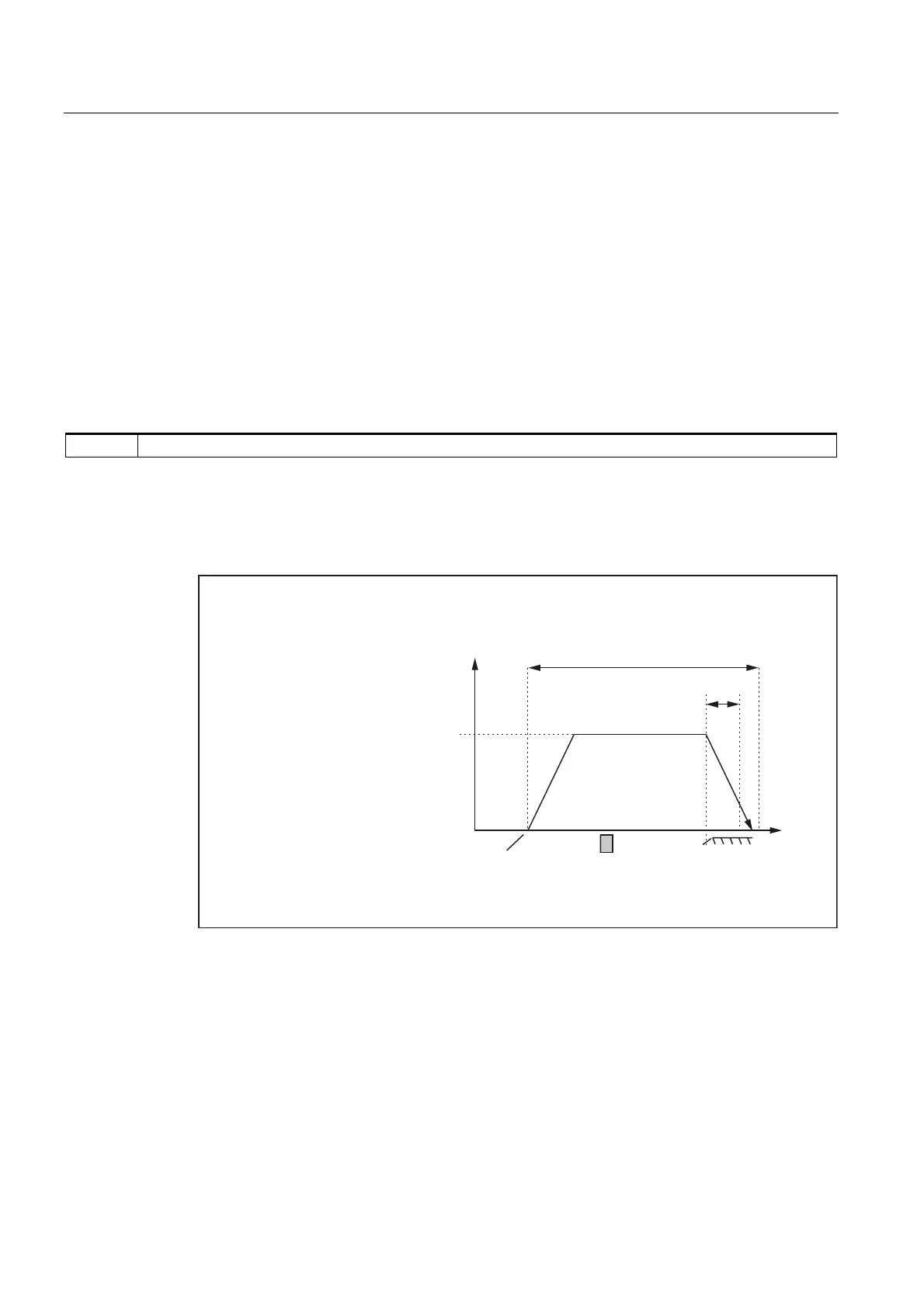

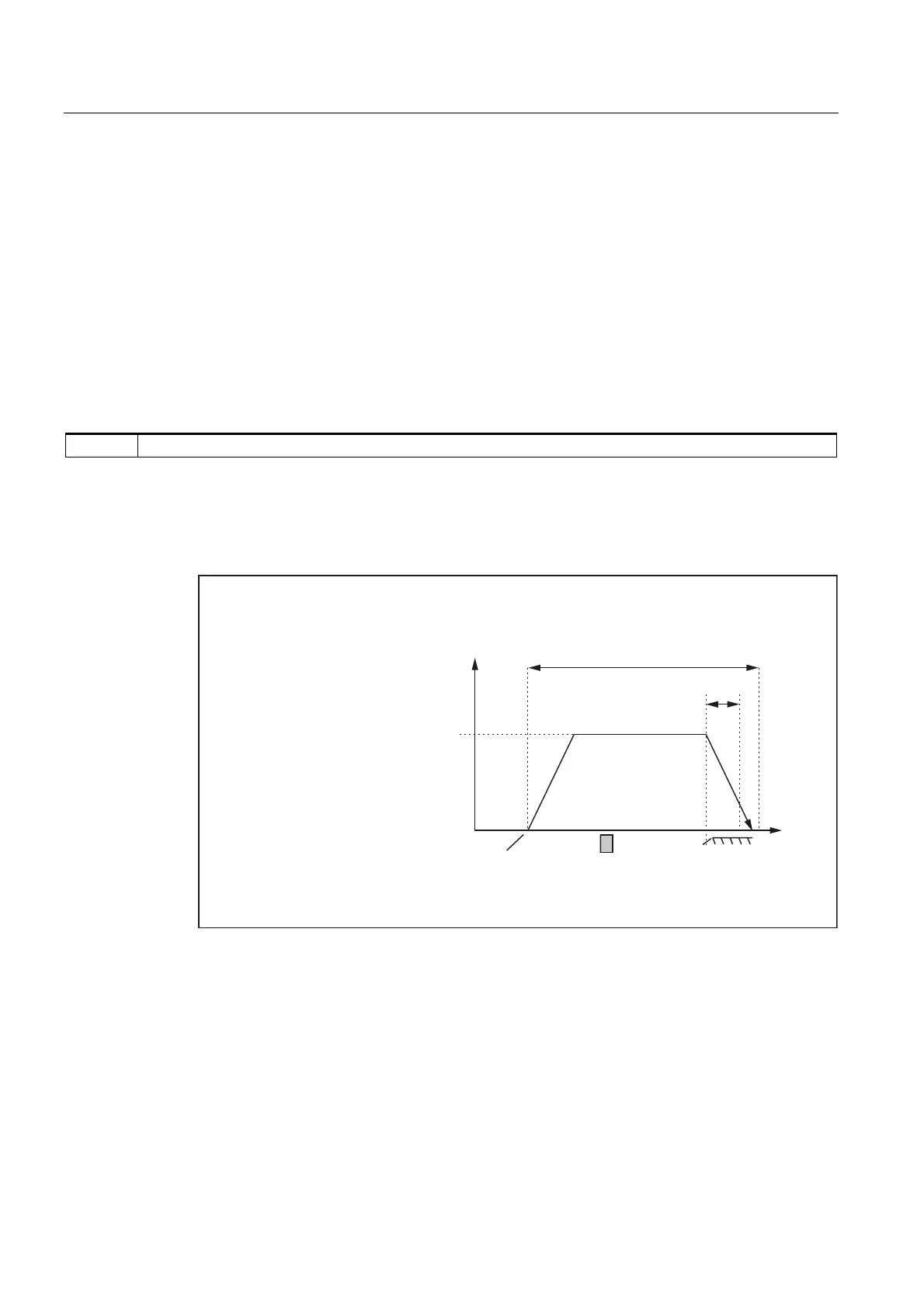

Case 1: The machine axis is positioned before the reference cam

When reference point approach is started, the machine axis accelerates in the assigned

direction:

MD34010 $MA_REFP_CAM_DIR_IS_MINUS (approach reference point in minus direction)

to the assigned reference point approach velocity before the reference cam:

MD34020 $MA_REFP_VELO_SEARCH_CAM.

The PLC user program communicates to the NC that the reference cam has been reached

via the following interface signal:

DB31, ... DBX12.7 (reference point approach deceleration)

As a result the NC decelerates to zero speed. In so doing, the following distance S

min

is

traversed, at a minimum:

S

min

= (MD34040 $MA_ REFP_VELO_SEARCH_MARKER)

2

/ 2 * (MD32300 $MA_MAX_AX_ACCEL)

This minimum distance must be covered to ensure that the machine axis exits the reference

cam in phase 2 at the assigned reference point creep velocity.

Phase 1 is now complete. Reference point approach is continued with Phase 2.

UHIHUHQFHSRLQWDSSURDFKYHORFLW\

6WDUWLQJSRVLWLRQ

RID[LV

0LQLPXPGLVWDQFH

5HIHUHQFHSRLQWFDP

9HORFLW\

PD[LPXPGLVWDQFHWRUHIHUHQFHFDP

=HURPDUN

'LVWDQFH

0'0$B5()3B0$;B&$0B',67

0'0$B5()3B9(/2B6($5&+B&$0

Fig. 2-3 Minimum distance for deceleration

Loading...

Loading...