Detailed Description

2.7 Basic tool orientation

Tool Compensation (W1)

2-114 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

System variable $TC_DPV[t, d]

The purpose of system variable $TC_DPV[t, d] is to allow the simple specification of certain

basic orientations (parallel to coordinate axes) that are required frequently. The permissible

values are shown in the table below. The values in the first and second/third columns are

equivalent.

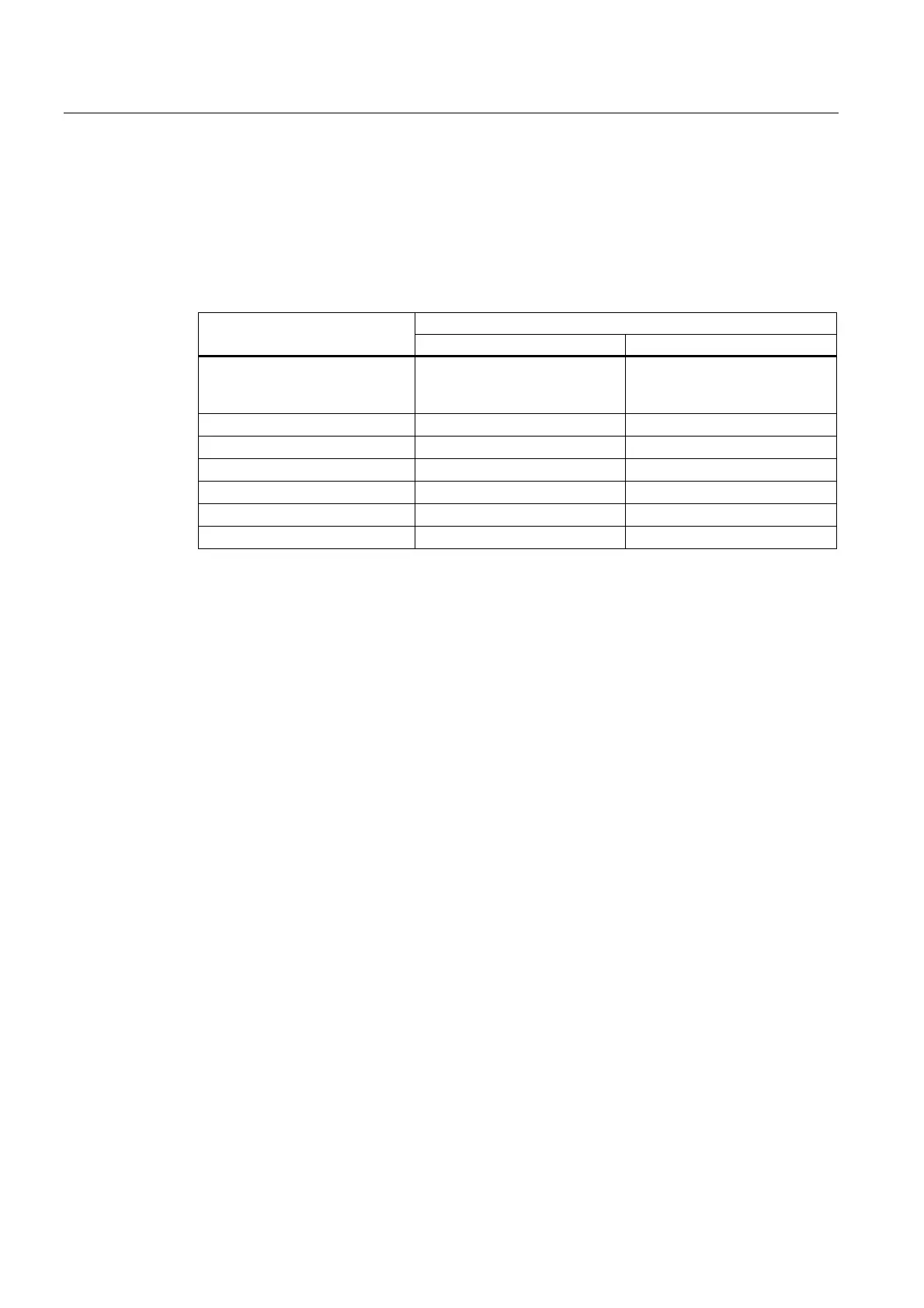

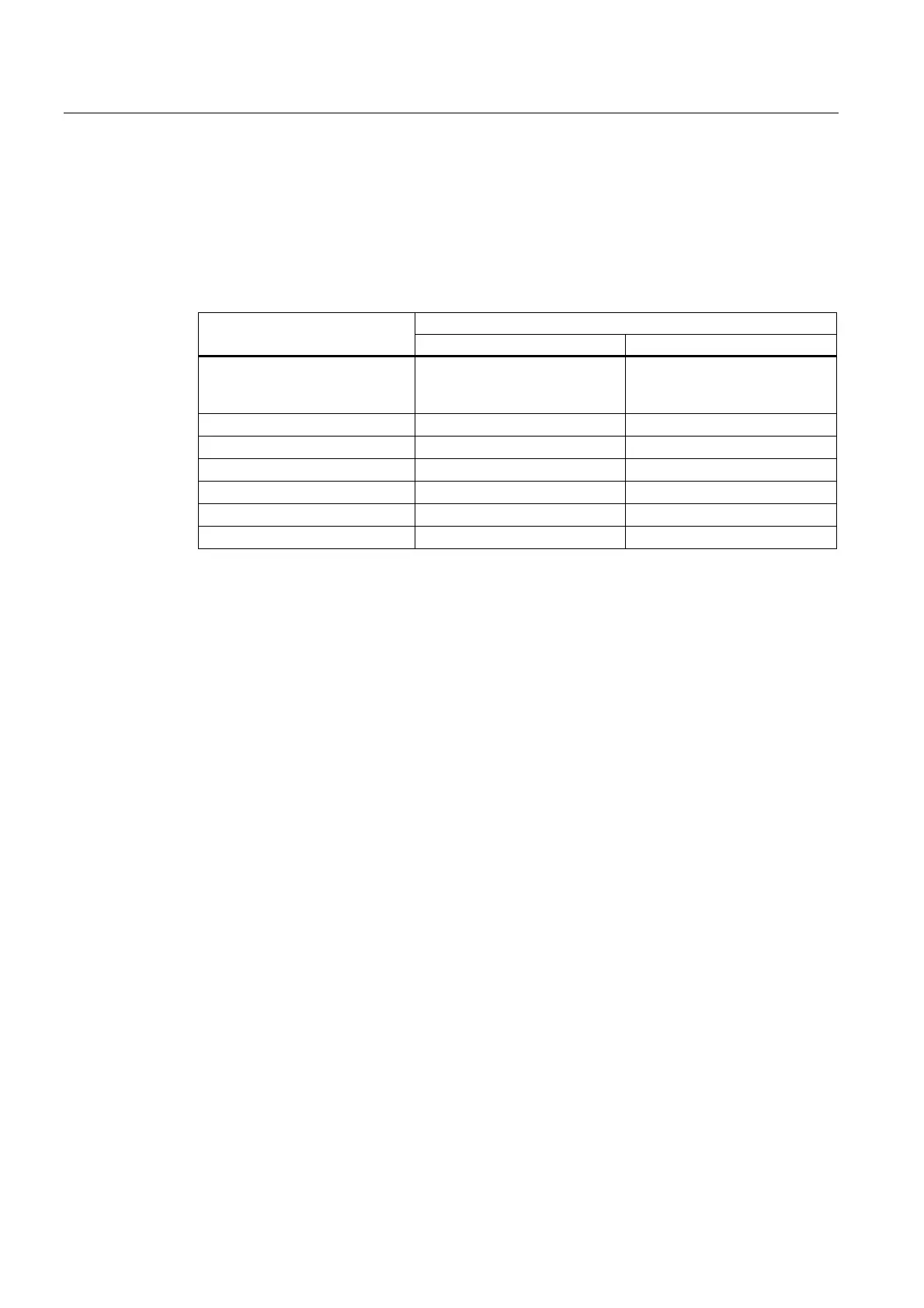

Basic orientation $TC_DPV[t, d]

Milling tools * Turning tools *

≤ 0 or > 6 ($TC_DPV5[t, d],

$TC_DPV4[t, d],

$TC_DPV3[t, d],) **

($TC_DPV3[t, d],

$TC_DPV5[t, d],

$TC_DPV4[t, d],) **

1 (0, 0, V) (0, V, 0)

2 (0, V, 0) (0, 0, V)

3 (V, 0, 0) (V, 0, 0)

4 (0, 0, -V) (0, -V, 0)

5 (0, -V, 0) (0, 0, -V)

6 (-V, 0, 0) (-V, 0, 0)

* Turning tools in this context are any tools whose tool type ($TC_DP1[t, d]) is between 400 and

599. All other tool types refer to milling tools.

** If all three values $TC_DPV3[t, d], $TC_DPV4[t, d], $TC_DPV5[t, d] are equal to zero in this

case, the tool orientation is determined by the active machining plane (default).

V Stands for a positive value in the corresponding system variables.

Example:

For milling tools,

$TC_DPV[t, d] = 2

is equivalent to

$TC_DPV3[t, d] = 0, $TC_DPV4[t, d] = 0, $TC_DPV5[t, d] = V.

Supplementary conditions

If the "Scratch" function is used in the RESET state, the following must be noted with respect

to the initial setting:

• The wear components are evaluated depending on the initial settings of the G-code

groups TOWSTD, TOWMCS and TOWWCS.

• If a value other than the initial setting is needed to ensure correct calculation, scratching

may be performed only in the STOP state.

Loading...

Loading...