Detailed Description

2.1 Various interface signals and functions (A2)

NC/PLC Interface Signals (Z1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-29

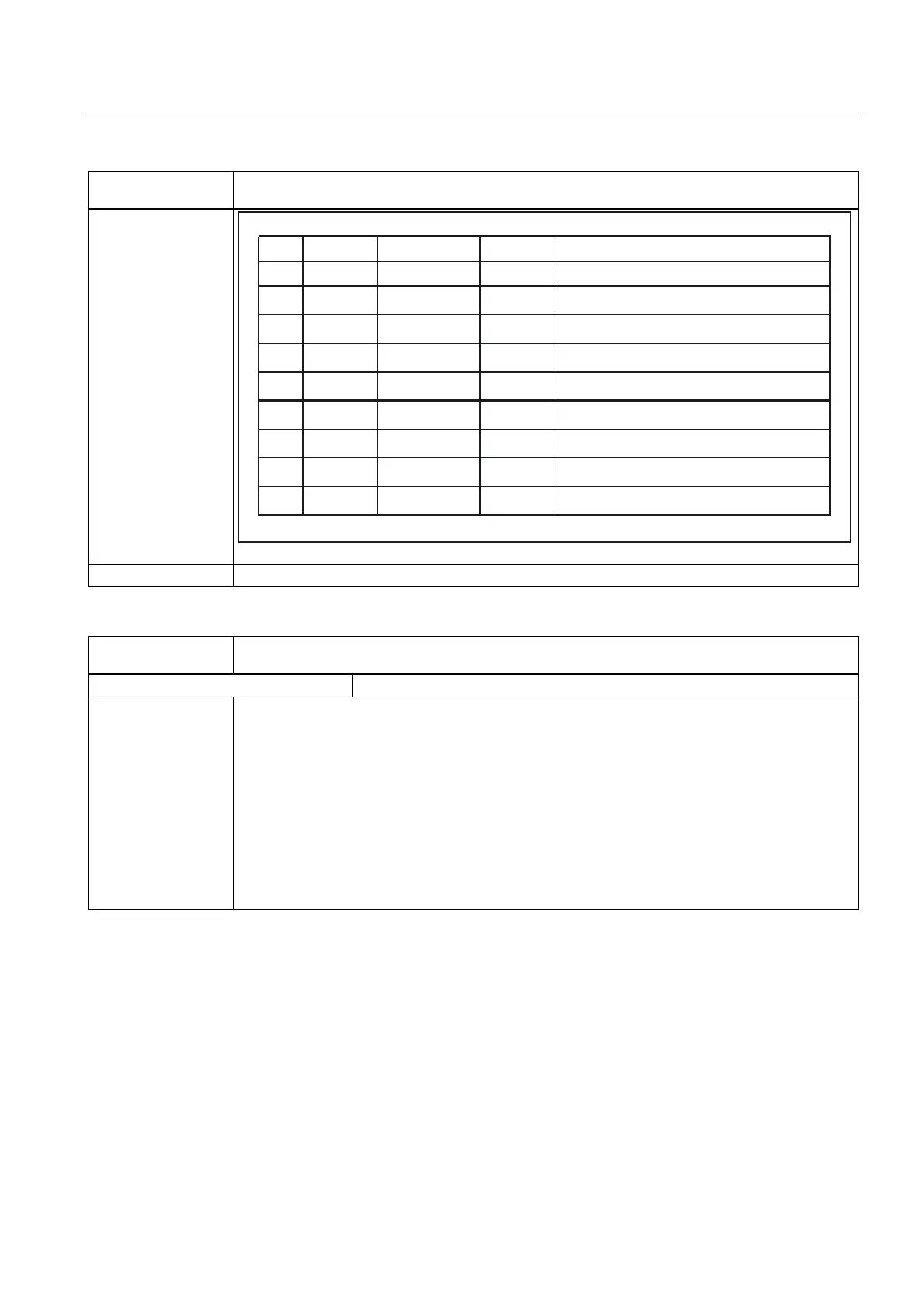

DB31, ...

DBX1.3

Axis/spindle disable

QRWVHWVHW

1R

&RXSOLQJ

3URFHGXUH

)6)$/6/$

2II

2II

2II

2II

21

21

21

21

6HWSRLQWVRID[HVDUHRXWSXW

1RVHWSRLQWRXWSXWIRU)6)$

1RVHWSRLQWRXWSXWIRU/6/$

1RVHWSRLQWRXWSXWIRU/6/$DQG)6)$

6HWSRLQWVRID[HVDUHRXWSXW

'LVDEOHQRWHIIHFWLYHIRU)6)$

'LVDEOHDOVRHIIHFWLYHIRU)6)$

1RVHWSRLQWRXWSXWIRU/6/$DQG)6)$

Corresponding to .... DB21, ... DBX33.7 (program test active)

DB31, ...

DBX1.4

Follow-up mode

Edge evaluation: no Signal(s) updated: cyclic

Signal state 1 Follow-up mode is selected for the axis/spindle by the PLC.

The means that the position setpoint continually tracks the actual value if the controller enable for

the drive is withdrawn.

As soon as the follow-up mode is effective, the interface signal:

DB31, ... DBX61.3 (follow-up mode active)

is set to a 1 signal.

The actual value continues to be acquired and updated. If the axis/spindle is moved from its current

position by an external effect the zero speed and clamping monitoring do not issue an alarm.

When the closed-loop control system is reactivated, a control-internal repositioning operation is

performed (REPOSA: linear approach with all axes) to the last programmed position if a part

program is active.

Loading...

Loading...