Tool offsets

8.6 Tool orientation (ORIC, ORID, OSOF, OSC, OSS, OSSE, OSD, OST)

Job planning

8-34 Programming Manual, 03/2006 Edition, 6FC5398-2BP10-1BA0

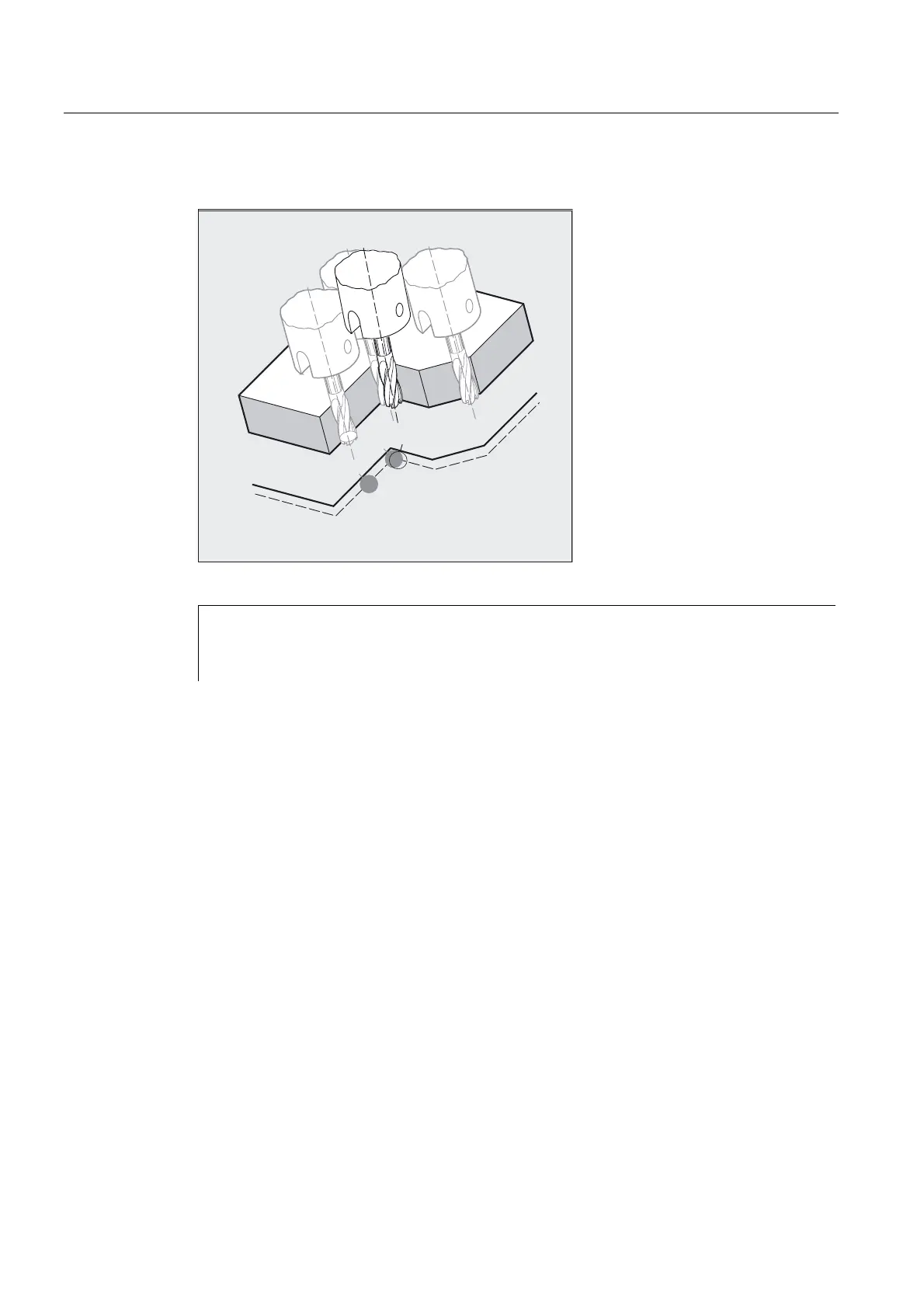

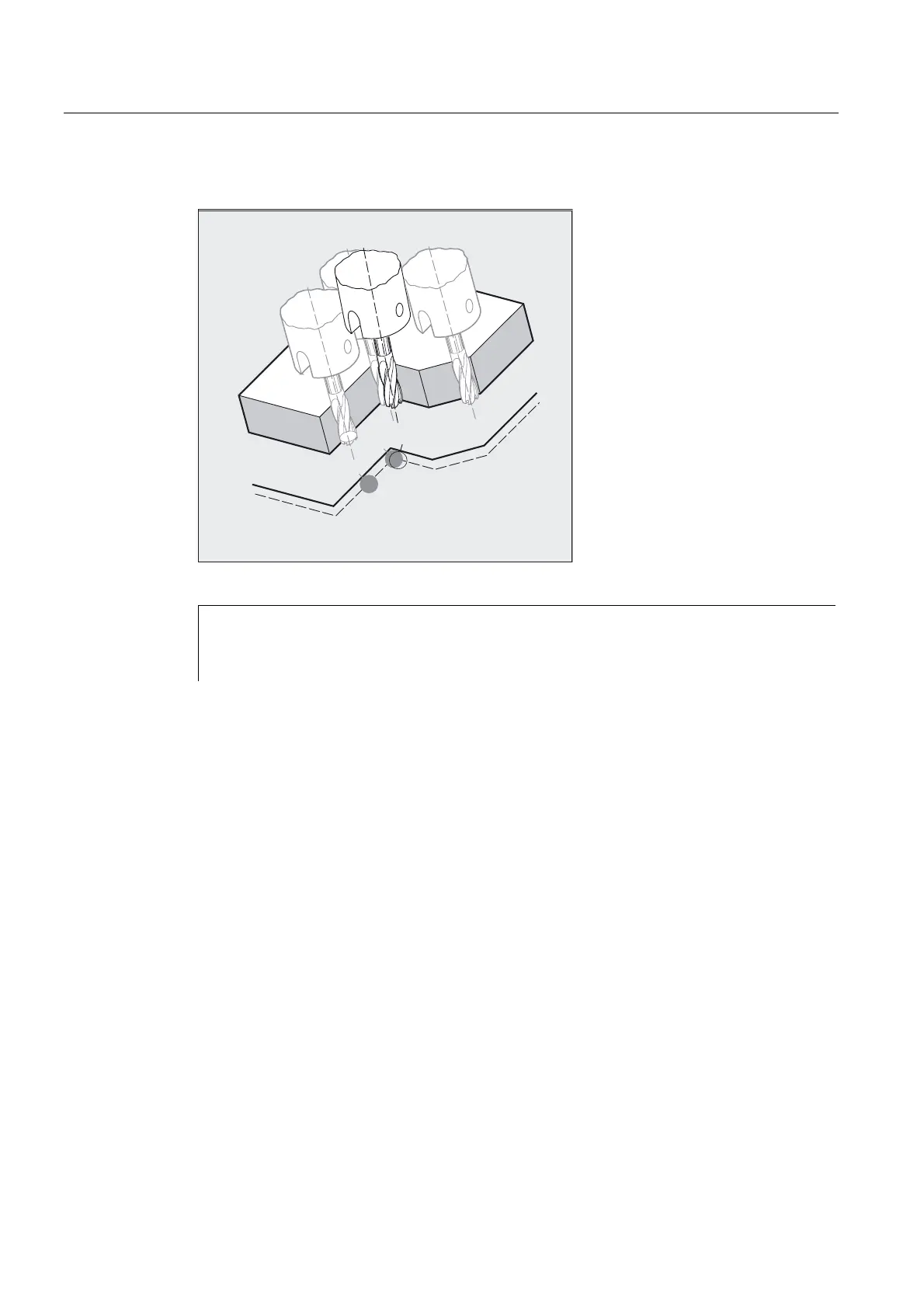

Example for the change in orientation at an inner corner

1

1

1

:5.

ORIC

N10 X …Y… Z… G1 F500

N12 X …Y… Z… A2=… B2=…, C2=…

N15 X Y Z A2 B2 C2

Loading...

Loading...