Motion synchronous actions

10.3 Main run variables for synchronized actions

Job planning

10-20 Programming Manual, 03/2006 Edition, 6FC5398-2BP10-1BA0

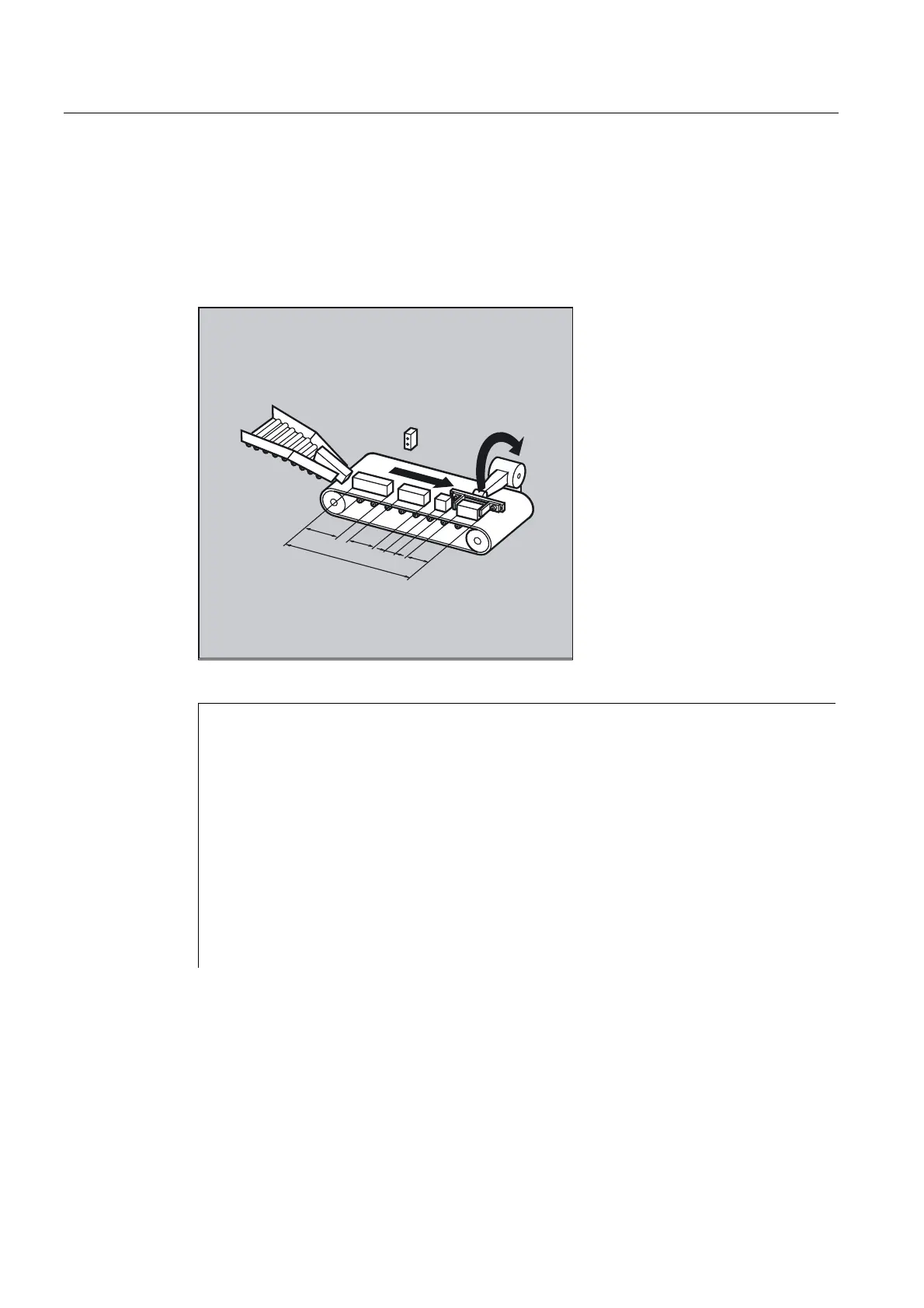

Example of the circulating stack

During a production run, a conveyor belt is used to transport products of different lengths

(a, b, c, d). The conveyor belt of transport length therefore carries a varying number of

products depending on the lengths of individual products involved in the process. With a

constant speed of transport, the function for removing the products from the belt must be

adapted to the variable arrival times of the products.

O

G

F

E

D

DEF REAL INTV=2.5 ;Constant distance between products

;placed on the belt.

DEF REAL TOTAL=270 ;Distance between length measurement

;and removal position.

EVERY $A_IN[1]==1 DO $AC_FIFO1[4]=0 ;Reset FIFO at beginning of process.

EVERY $A_IN[2]==1 DO $AC_TIMER[0]=0 ;If a product interrupts the light

;barrier, start timing.

EVERY $A_IN[2]==0 DO $AC_FIFO1[0]=$AC_TIMER[0]*$AA_VACTM[B]

;If the light barrier is free, calculate and store in the FIFO the

product length fromthe time measured and the velocity of transport.

EVERY $AC_FIFO1[3]+$AC_FIFO1[4]*ZWI>=TOTAL DO POS[Y]=-30

$R1=$AC_FIFO1[0]

;As soon as the sum of all product lengths and intervals between products is greater

than or equal to the length between the placement and the removal position, remove

the product from the conveyor belt at the removal position, read the product length

out of the FIFO.

Loading...

Loading...