© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

Key functions for 5-axis machining

3.6

67

3.6.1 Compressor – COMPCAD

The compressor is ideally called in CYCLE832. If it is to be programmed separately, then pro-

ceed as described below.

Explanation of the commands

Operating principle of the compressor

Programming

COMPOF

COMPCAD

COMPCURV

COMPOF Compressor off

COMPCAD Compressor on - surface quality and speed are further optimized.

COMPCAD smoothes the points along the characteristic before

approximation

(B spline) and offers, at a high path velocity, the highest degree of

accuracy with transitions that have a constant acceleration rate.

Preferably used to mill free-form surfaces (recommended).

COMPCURV Compressor on

G1 blocks are approached using a polynomial. Block transitions

are jerk-free. Preferably used for circumferential milling.

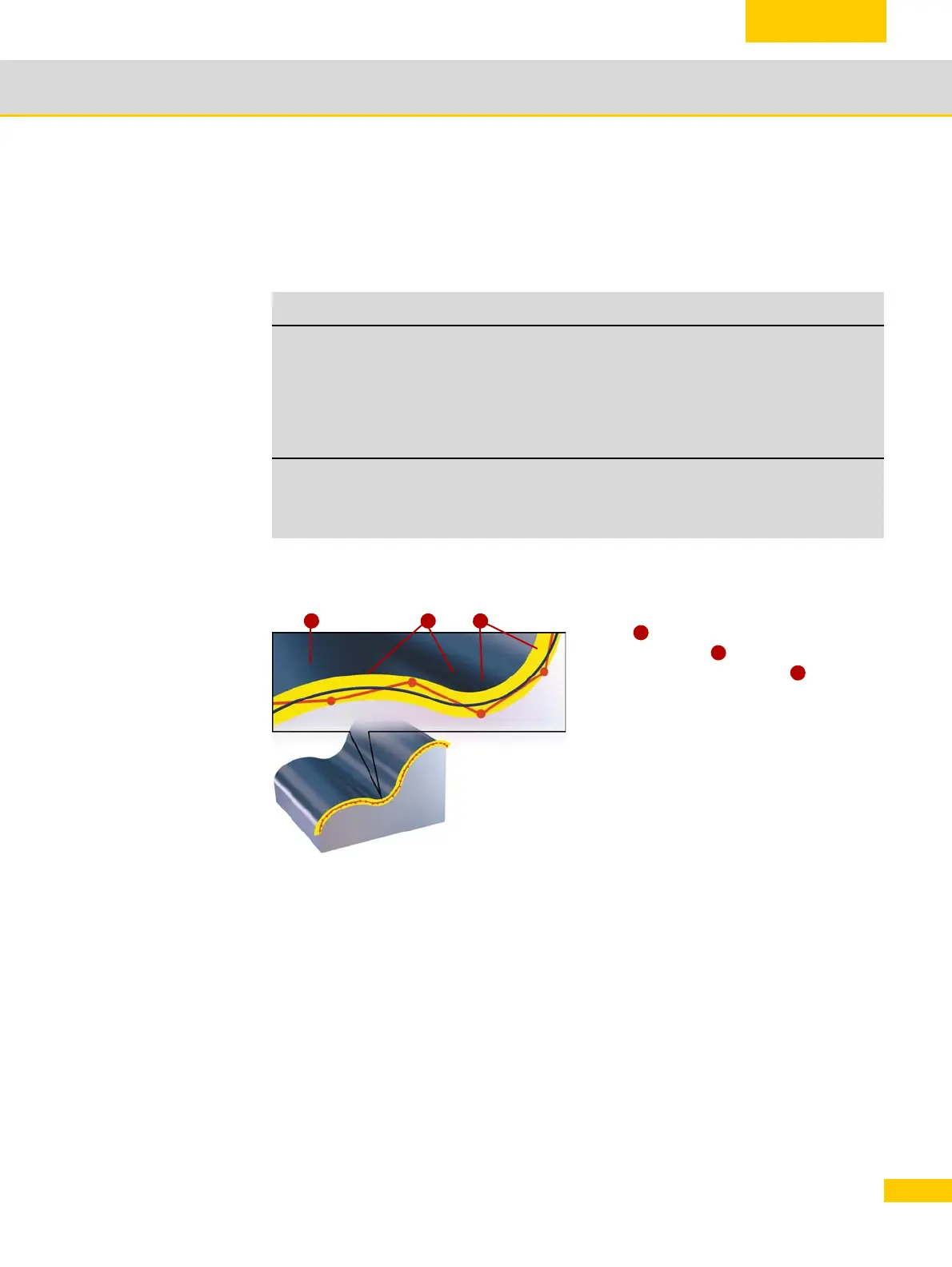

In accordance with the specified tolerance

band, the compressor takes a sequence

of G1 commands, combines them and

compresses them into a spline , which can

be directly executed by the control. A new

contour is created whose characteristic lies

within the specified tolerance range.

The compressor generates smooth paths and

paths with constant curvature. The constant

curvature results in a steady velocity and

acceleration characteristic, meaning that the

machine can run at higher speeds, thereby

increasing productivity.

1 2 3

1

2

3

Loading...

Loading...