Key functions for 5-axis machining

3.6

© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

68

3.6.2 Continuous-path mode, Look ahead – G64, G641,

G642

If you call continuous-path mode within CYCLE832, in the case of G642 for example, the toler-

ance value from CYCLE832 will correspond to the smoothing value for G642.

Explanation of the commands

Using G64, G642

G64 Continuous-path mode – Look ahead where the axis only brakes

at corners

G642 Smoothing with axial tolerance (recommended)

Look ahead with additional corner rounding corresponding to

MD 33100 (machine data)

The following applies to G642: There are 2 ways of specifying the

tolerance:

1. Specifying individual axes

or

2. Programming the retraction distance via ADIS

Preferably used to mill free-form surfaces

G641 In the case of G641, the control inserts transition elements at con-

tour transitions.

You can use ADIS=… and ADISPOS=… to specify the extent to

which the corners are rounded.

ADIS= Smoothing distance for path functions G1, G2, G3.

If no ADIS value is specified, the control will use the tolerance

value from CYCLE832.

ADISPOS= Smoothing distance for rapid traverse G0 (not suitable for free-

form surfaces)

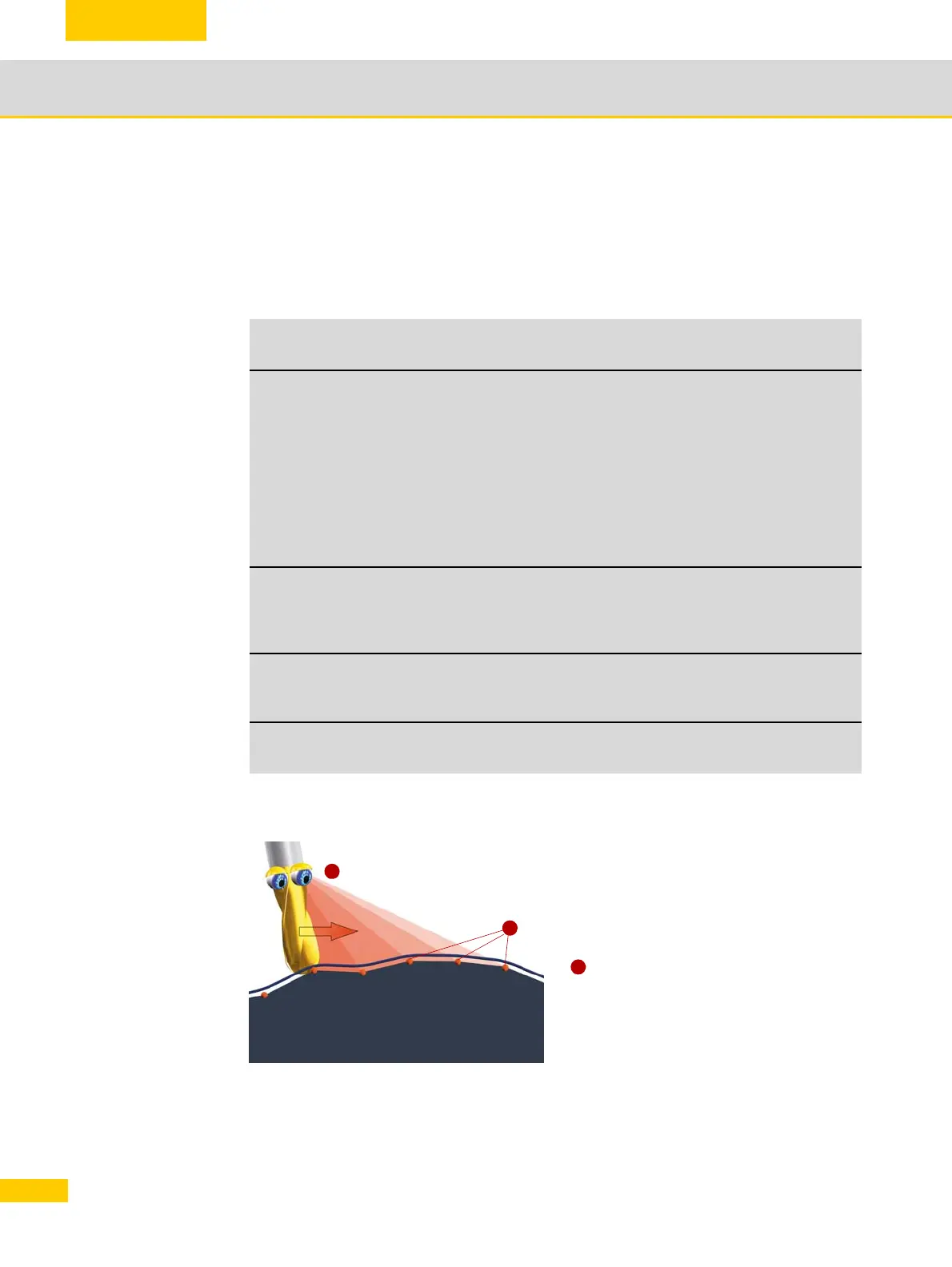

The objective of continuous-path mode is to

increase the speed and harmonize the tra-

versing behavior. For the continuous-path

functions G64 etc. this is implemented by

means of two functions.

Look ahead - anticipatory velocity control

The control calculates several NC blocks in

advance and determines a modal velocity pro-

file. The way in which this velocity control is

calculated can be set using the functions G64

etc.

1

G1

G1

G1

G1

G1

G1

2

1

Loading...

Loading...