Operating manual - English Technica EU

14 Copyright Silca 2005

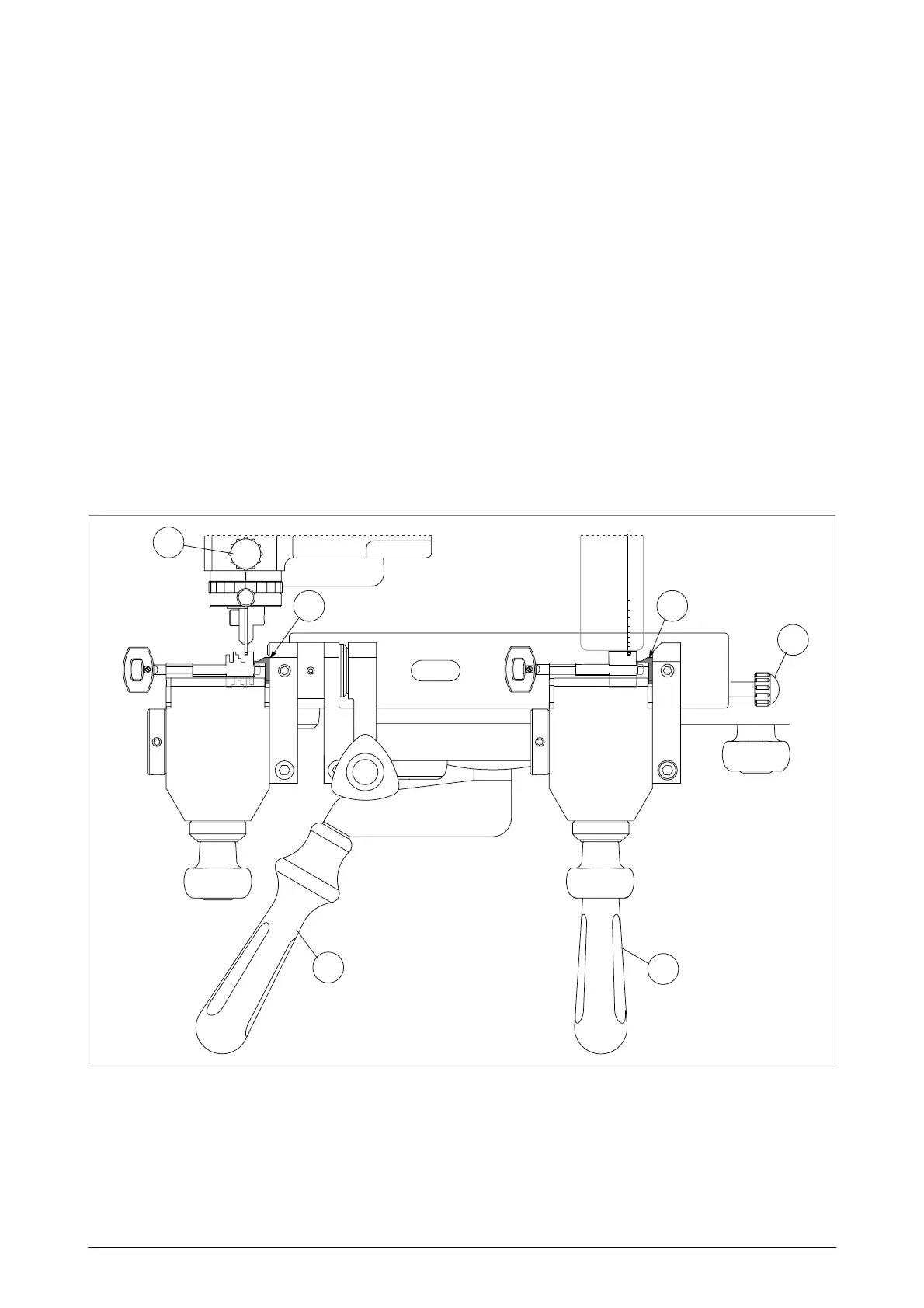

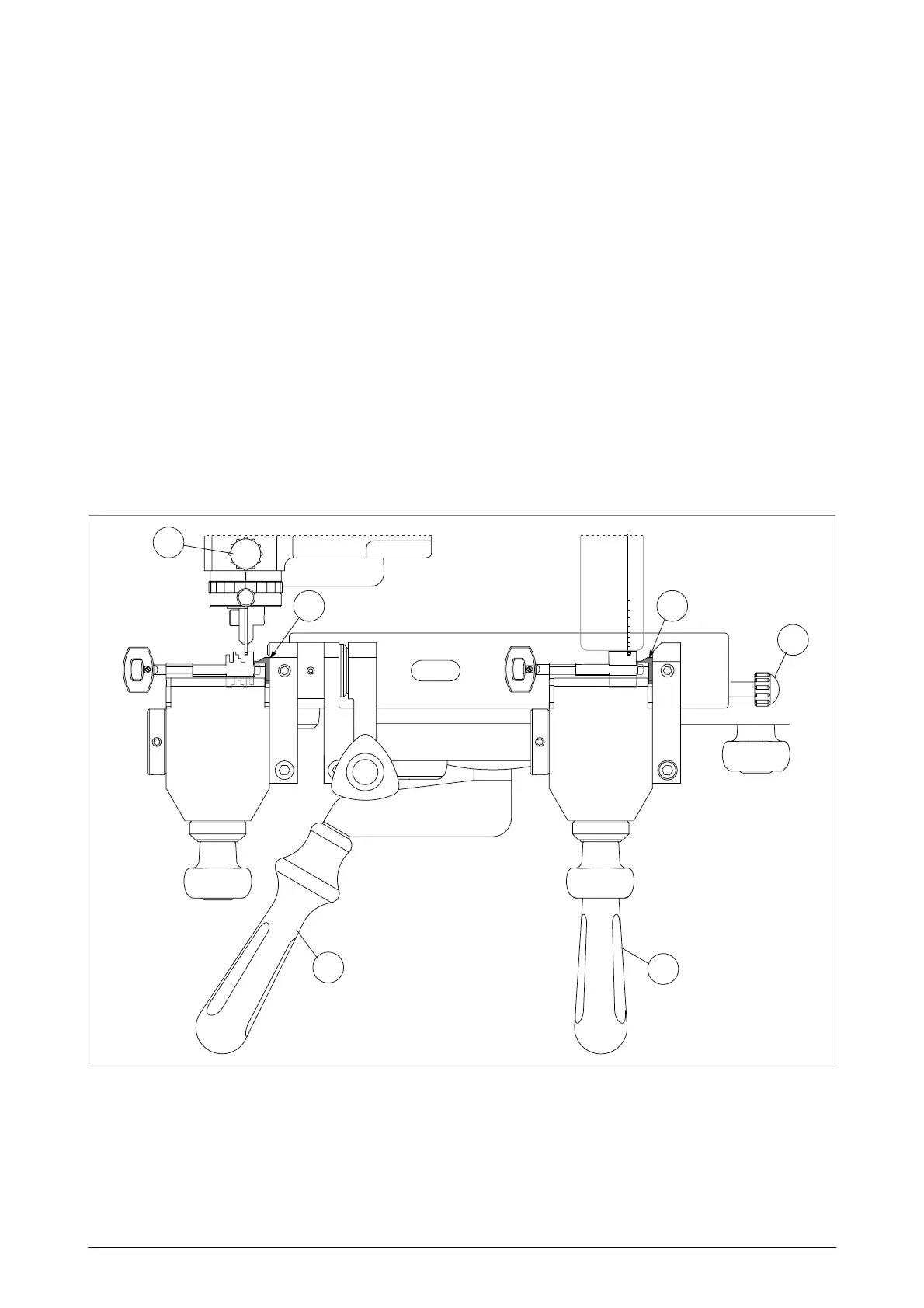

4.7 Cutting operations

ATTENTION: to work in complete safety, pay special attention to the following recommendations:

•

start the motor only when all the operations with the carriage have been carried out (securing keys,

etc

.)

• always work with dry hands.

• check that the machine is properly earthed.

• use the protective goggles, even if the cutting tool is fitted with a protective shield.

• keep the hands away from the cutting tool when in motion.

4.8 Cutting bit and double bit keys - male

1) Use the knob (S) to lock the right-hand clamp in a horizontal position.

2) Place the keys into the jaws, pushing them to the right until the bit is in contact with the key stop (Y). Close the

jaws, taking care that the keys are securely fitted into their seating and that the bits of the two keys are parallel.

3) Release the right-hand clamp by pulling out the knob (S).

4) Switch the motor commutator to the correct position (1 = low speed for steel keys, 2 = high speed for brass

keys); turn the machine on and use lever (L) to take the carriage slowly towards the cutter, at the same time

raising lever (R) very slightly. With the clamp positioned lower than the cutter, starting from the right, cut the

key, lowering lever (R) to round off the cut. The spring incorporated in the carriage helps the operator by

returning the rocking clamp to its original cutting condition.

5) Cut the whole bit and remove any burrs at the end of the cutting operation.

6) When the cutting operation is complete, turn the switch to “0” and remove the keys.

7) For double bit keys, turn both keys and repeat the operations described above.

Fig. 18

S

JJ

L

R

D1

Loading...

Loading...