.

The table below gives the values to set

whenthesupplygasischanged:

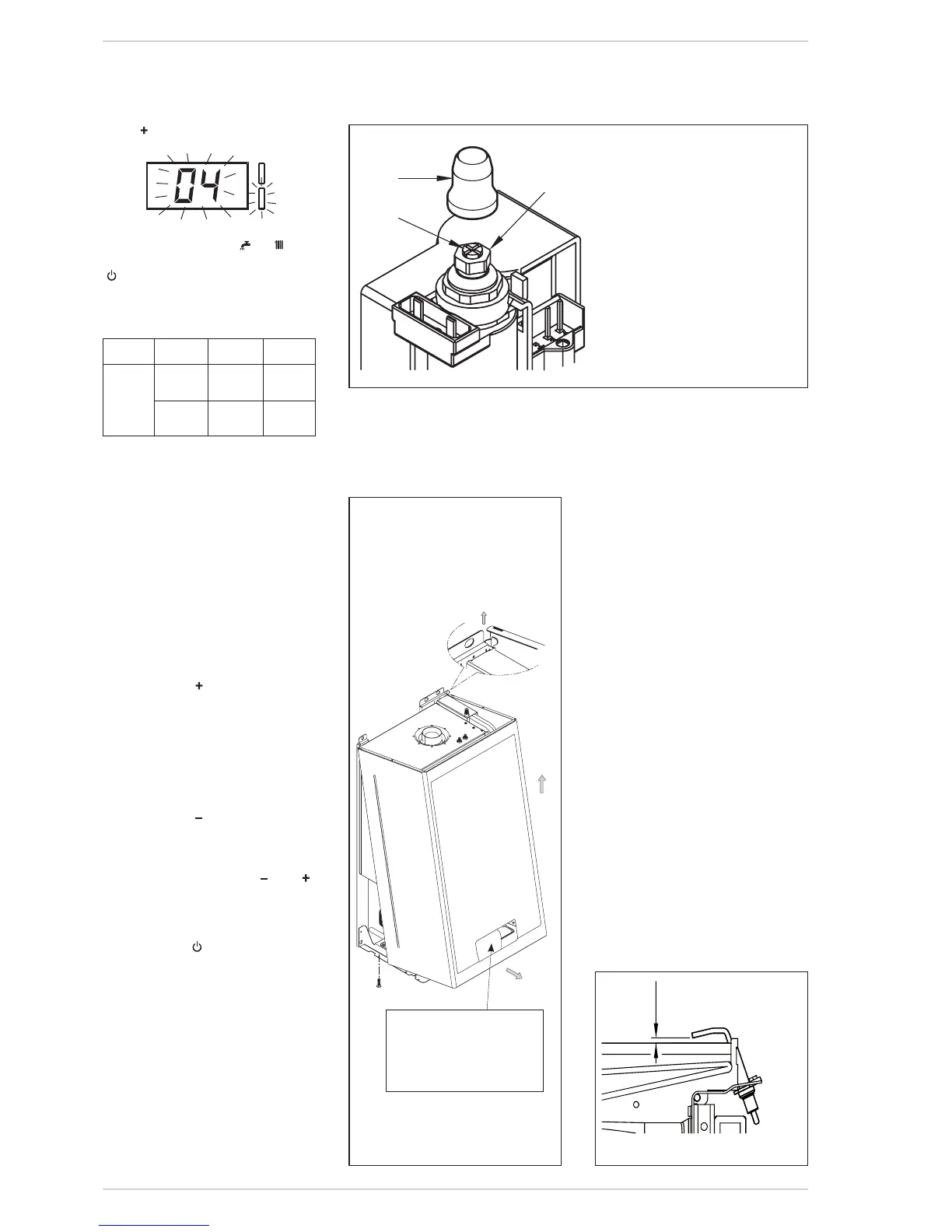

6.4.2.2 Adjusting valve pressure

(fig. 24)

Setmaximumandminimumpressureon

gasvalvesasfollows(fig.24):

– Connect a manometer to the intake

downstream of the gas valve (4 fig.

22).

Disconnect the valve VENT pressure

test point tube (5 fig. 22).

– Removethecap(1)fromthemodula-

tor.

- Puttheboilerinchimneysweepmode

(see section 6.4.4.2), ensure that ane

zonevalvesareopen.

– Pressthekey

againtoquitthefun-

ction.

– RefitthevalveVENTpipe.

– Remove the manometer, remembe-

ring to tighten the screw for closing

thepressuretestpoint.

– Put the plastic cap (1) back on the

modulator. Check all test points and

connectionsforgastightness.

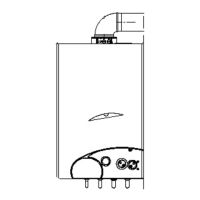

6.4.3 DISMANTLING

THE CASING (fig. 25)

The casing may be removed complete-

ly to facilitate boiler maintenance, as

showninfig. 25.Turn thepanel control

forwardforaccess totheinternal com-

ponentsoftheboiler.

6.4.4 MAINTENANCE

To guarantee functioning and efficien-

cy of the appliance, in respect of the

legal provisions in force, it must be

regularly checked; the frequency of the

checks depends on the type of instal-

lation and usage but this should be at

least annually.

Carry out the following procedure for

cleaningtheburner/heatexanger:

– Isolate the boilers electrical supply

andclosethegasisolationvalve.

– Removethe outercasingasshownin

fig.25;removethecombustioncham-

bercoverandtheburnercover.

– Idealyuseavacuumcleanerandasoft

brushtoremoveanydebris;takecare

nottodamagetheinsulationpanel.

- Clean the heat exchanger, removing

anydustorresiduefromcombustion.

- Whencleaning theheat exchangeror

theburner,chemicalproductsorsteel

brushesMUSTNOTBEUSED.

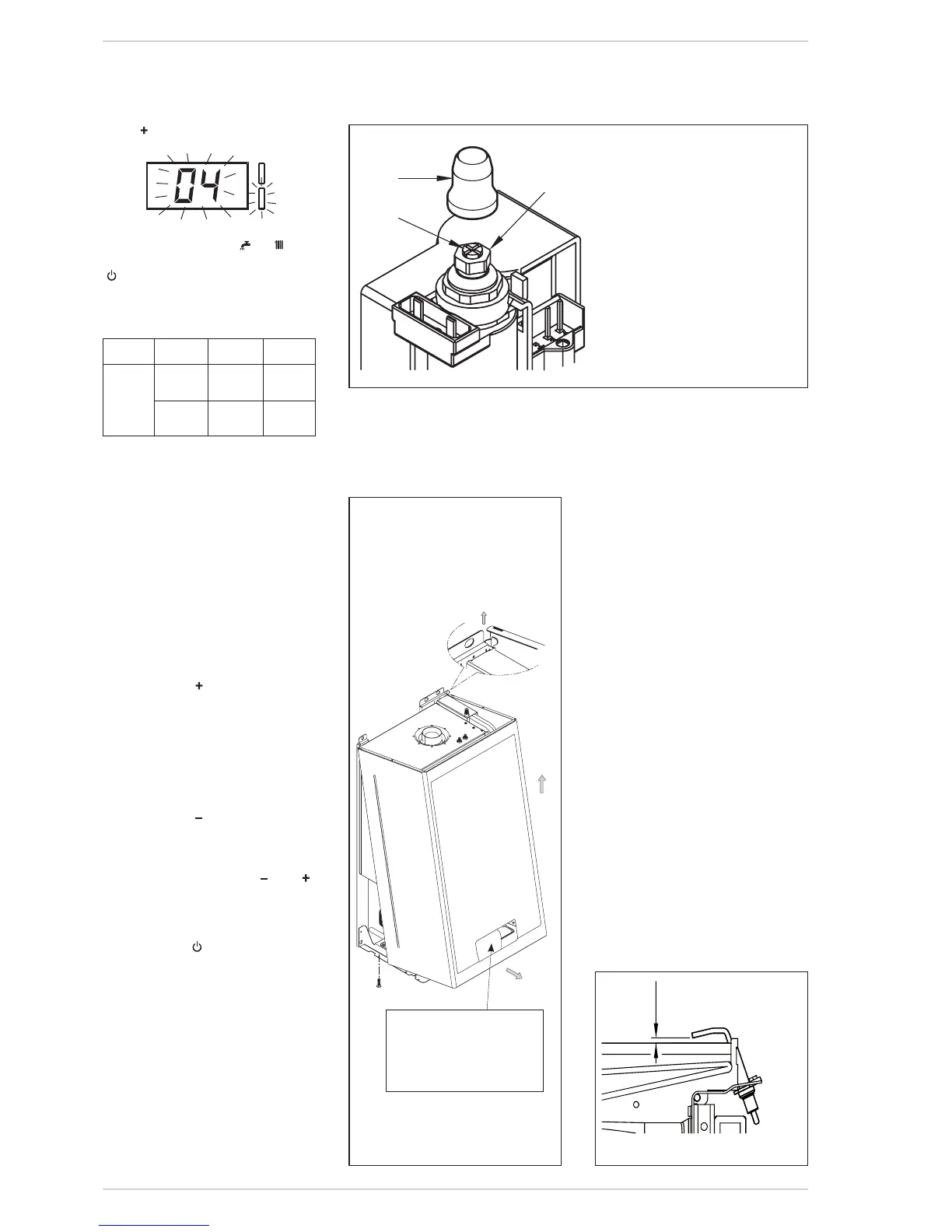

6.4.4.1 Ignition/Detection

electrode (fig. 27)

- Remove the casing, front panel and

sealedchambercovers.

- Unscrewthescrewsecuringtheelec-

trodeandremovefromtheburner.

- disconnecttheelectrodecable.

- Replacetheelectrodeandsetthegap

asshown.

Loading...

Loading...