8 Steering & Front Wheel Repair

Lower Steering Group

8 - 6

Figure 10. Remove Spindle Shaft Bushings

Punch marks

Figure 8. Remove Rod End

Figure 9. Inspect Rod End

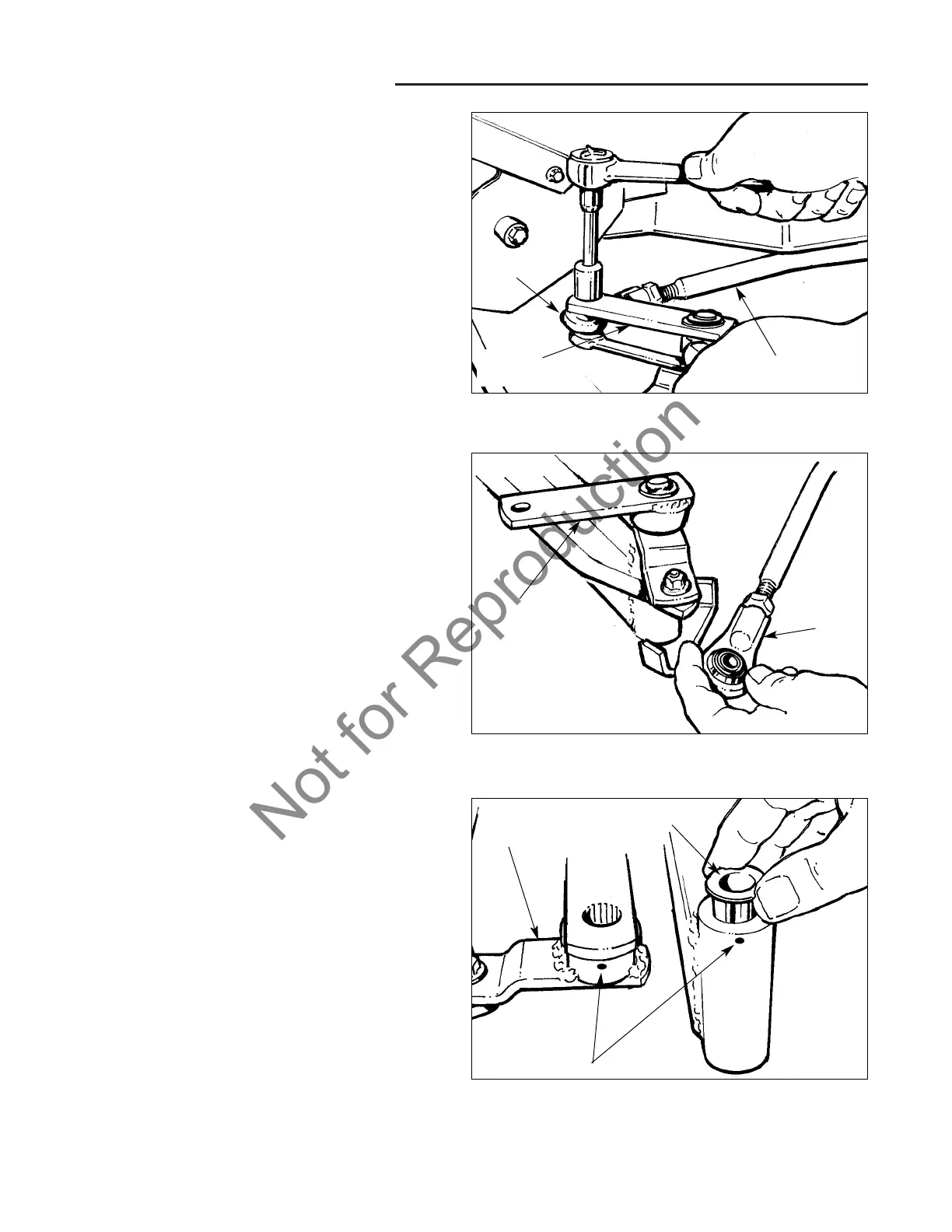

4. Using a 9/16" socket and 9/16" open end or box

wrench, remove the capscrew/washer and flanged

hex nut that secure the steering arm assembly to the

rod end (Figure 8).

NOTE: A spacer is located over the capscrew threads in

the rod opening to permit rotation of the steering arm.

Damage to the spacer or washer caused by excessive

tightening or wear may adversely affect steering, so be

sure to inspect these parts and replace them if neces-

sary before reassembly.

5. The rod end is screwed onto the drag link arm and is

secured in place with a 1/2-20 jam nut.

Rod

End

Drag Link

Steering

Arm

Steering

Arm

Rod

End

Steering

Arm

Bushing

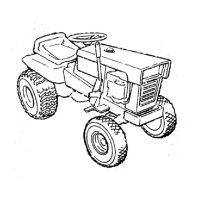

6. Inspect the rod end for free movement/rotation of the

rod end bearing, and replace the rod end if necessary

(Figure 9).

7. To remove the rod end, loosen the jam nut by turning

it clockwise (looking at the end of the drag link shaft)

one or two turns with a 3/4" open-end wrench, and

then unscrew the rod end by turning it counter-clock-

wise.

NOTE: When reinstalling the rod end, be sure to adjust

the length of the drag link arm so that the left and right

spindle stops stop against the axle assembly with full left

and right turns respectively. See the adjustment proce-

dures section for complete details.

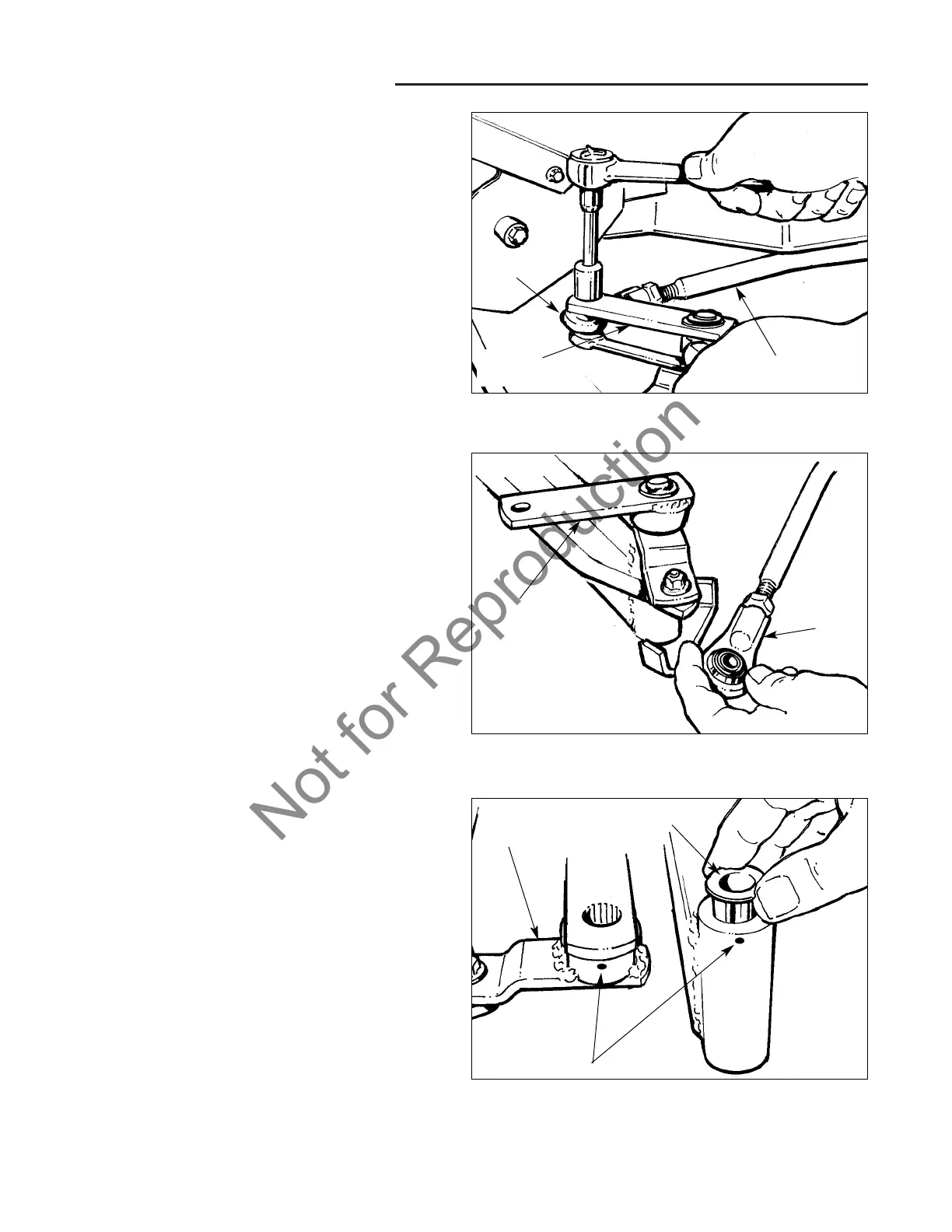

8. Tap the left hand steering arm assembly up off the

spindle shaft with a hammer to remove it from the

axle/spindle shaft assembly.

NOTE: It will be helpful to mark the relative positions of

the steering arm, splined spindle shaft, and shaft housing

with punch marks to simplify realignment later (See

Figure 10).

9. Tap the top of the splined spindle shaft down with a

few light hammer blows, and remove the spindle

shaft from the bottom of the axle assembly housing,

noting alignment.

10. With the spindle shaft removed, the bushings can be

removed and inspected for signs of wear (Figure 10).

Use a brass drift or punch to tap out the bushings

from opposite ends of the housing. Replace the

bushings if worn, scored, or cracked.

Loading...

Loading...