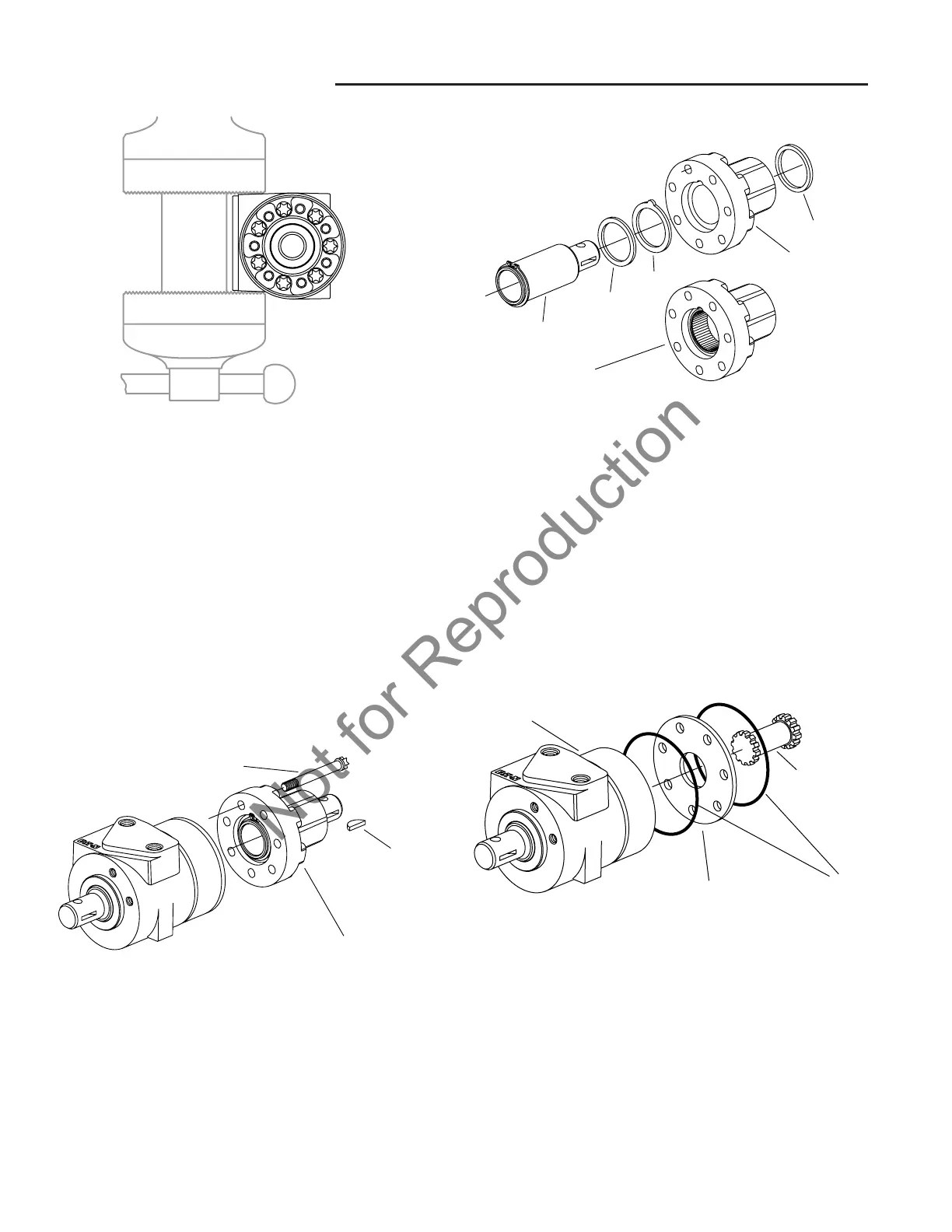

9 Torque Generator Repair

Tear-Down

9 - 4

Output Shaft

(power end) Up

Vise Jaws

(top View)

OUT

IN

AUX

Key

Cap Screw

Housing and Shaft Assembly

TEAR-DOWN AND REASSEMBLY

Tear-Down

1 To disassemble the torque generator, first support

the unit in a vertical position with the seven cap

screws up and control end shaft down.

NOTE: When a bench vise is used to support the torque

generator, do not to use excessive clamping pressure on

the control housing. Excessive pressure can distort the

housing. When using a vise, CLAMP ACROSS PORT

FACE SIDES ONLY.

2. With the torque generator firmly supported, use a 6

point drive socket wrench and remove seven cap

screws (early production units used 12 point drive

screws).

3. Remove the housing (power end) and shaft assem-

bly.

4. Turn the housing and shaft assembly over and

remove the shaft with retaining ring in place.

NOTE: In most cases it is not necessary to remove the

retaining ring from the shaft.

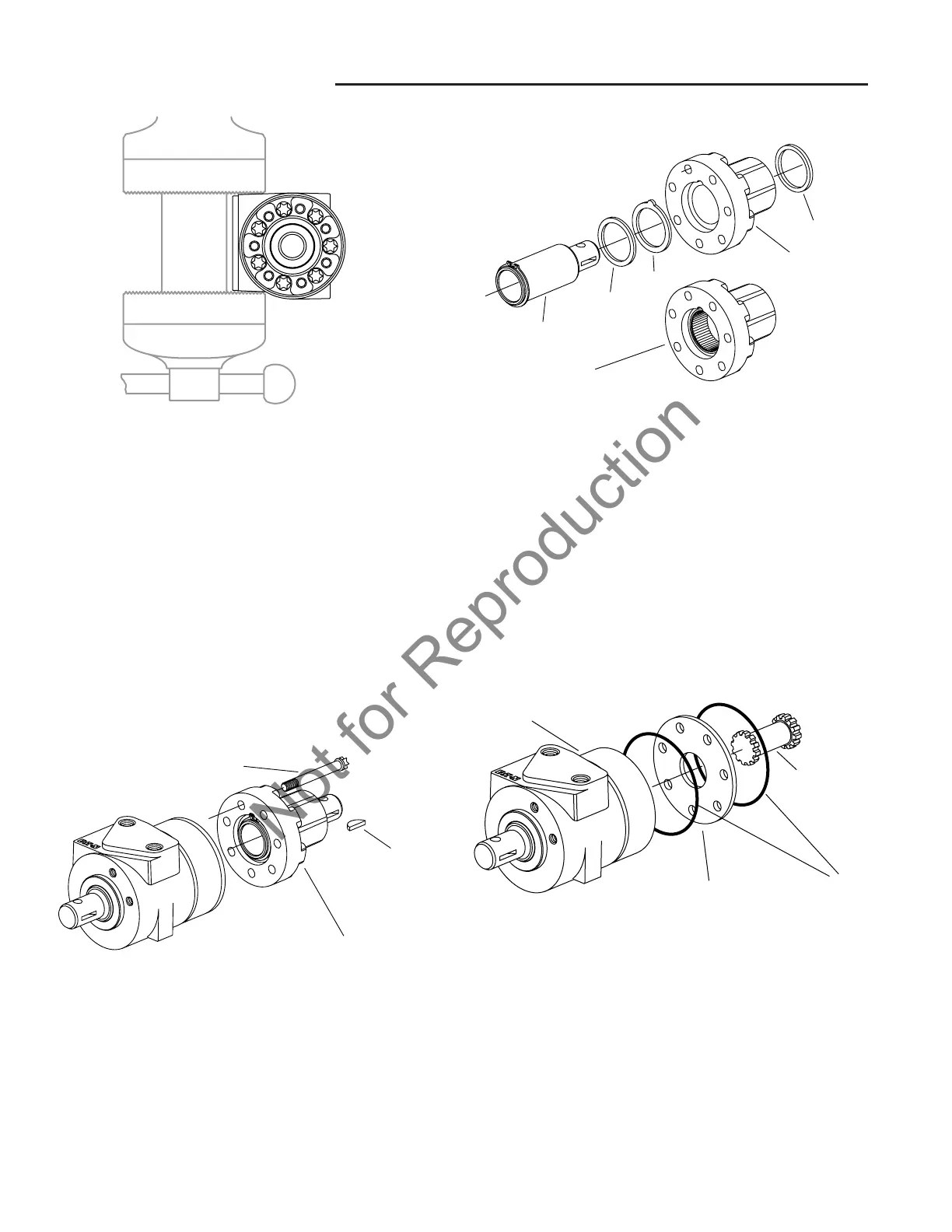

Quad Seal

Housing (Standard)

Housing (bearings—needle type)

Washer

Washer

Shaft and Retaining Ring

(power end)

OUT

IN

AUX

Drive

(power end)

O-ringSpacer Plate

Gerotor or Geroler

5. Remove both washers from the housing (power end),

and re-position the housing with seal end up. Use

small screw- driver or similar tool to remove quad

seal from the housing. Housing with two bearing sets

(needle type) use the same output shaft, quad seal,

washers, and retaining ring as the standard housing,

however if bearings are to be replaced they are not

sold separately as replacement parts.

6. Use a small screwdriver or similar tool to remove o-

ring from the spacer plate.

7. Remove spacer plate from the gerotor or Gerotor.

8. Remove drive (power end) from the gerotor or

Gerotor.

9. Remove o-ring from the gerotor or Gerotor.

Loading...

Loading...