LONGITUDINAL

FEED

LINKAGE (Continued)

SETTING

1:

(To

obtain

equal

distance)

Insert button to be sewn into clomp, engage

maa

chine

into

urun

11

position

and

rotate

machine

pulley

until

needle

is

just

above

button

(see

Fig.

28).

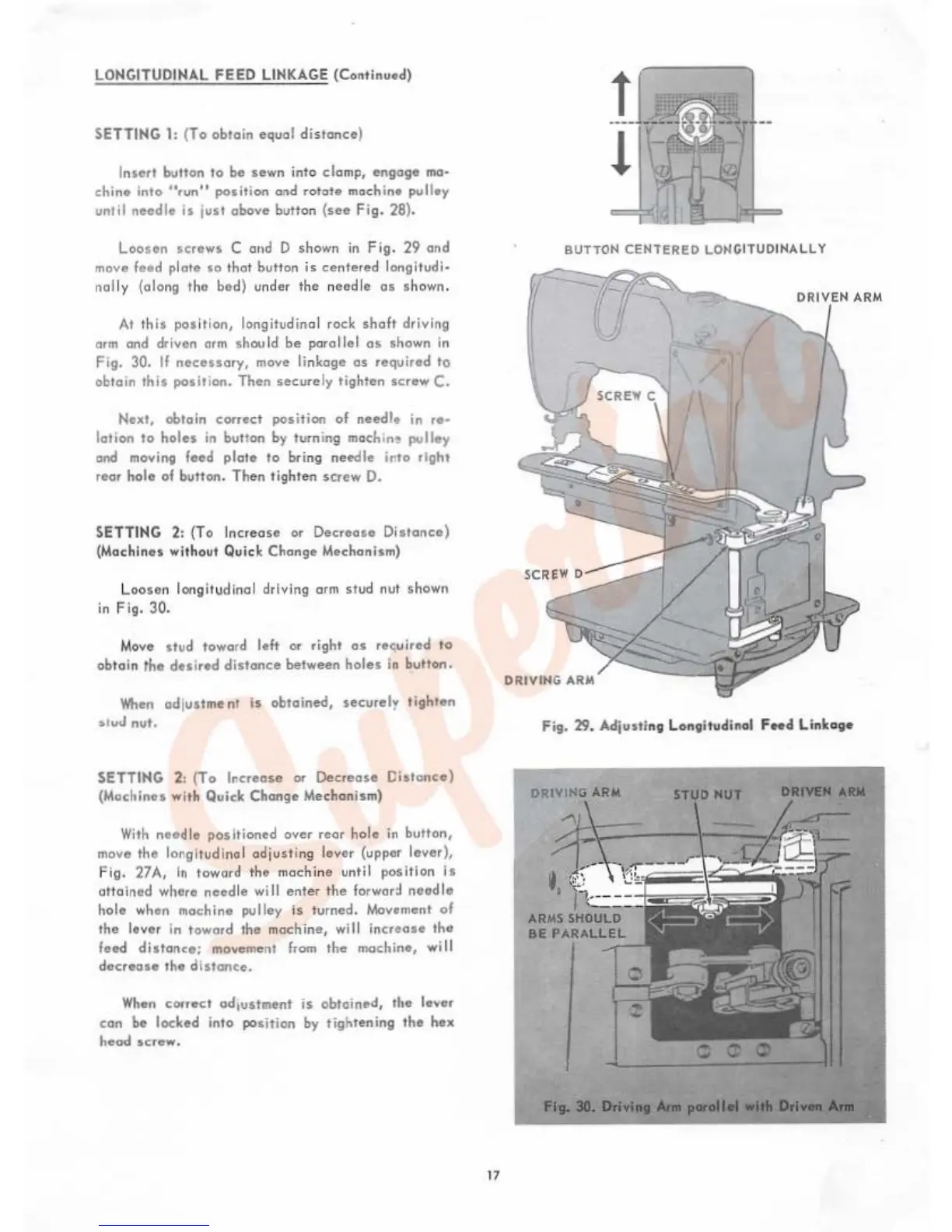

Loosen

screws

C and D shown

in

Fi

g.

29

and

move feed plate

so

that button

is

centered

longitvdi~

nally (along tho bod) under tho noodle

as

shown.

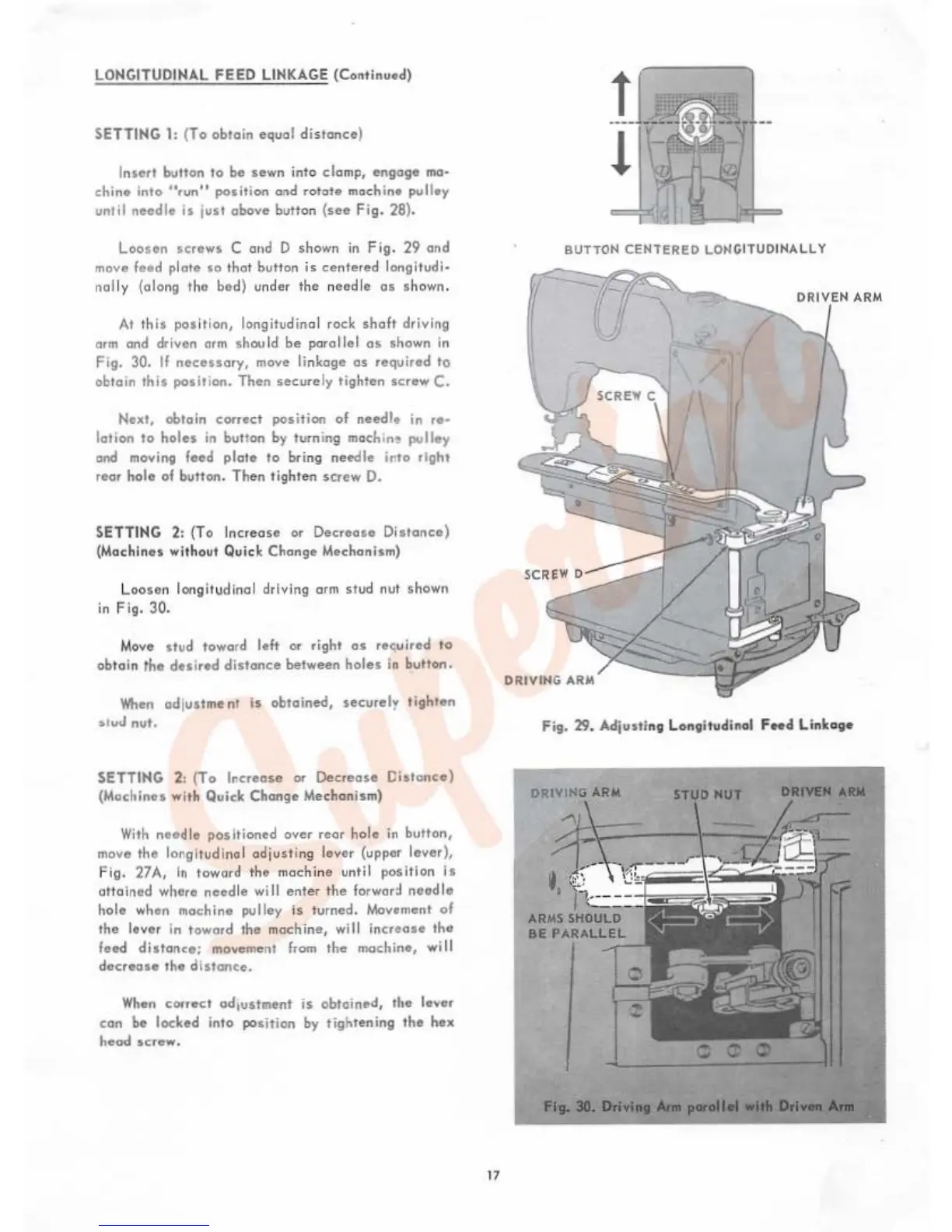

At

this

position,

longitu

dinal

rock

shaft

driving

arm

and

driven

arm

shou

ld be paral l

el

as shown in

Fig. 30. If

necessary,

move linkage

as

required to

obtain

this

posit1on. Then

securely

tighten

screw

C.

Next, obtain correct position

of

needle in ,

...

lotion to

holes

in button by turning

moch

i

n~

pulley

and moving feed

plate

to

bring

needle

irto

right

roar

halo

of burton.

Then

tighten

screw

D.

SETTING 2: (To Increase or

Decrease

Distance)

(Machines without Quick Change Mechanism)

Loosen longi

tu

dinal driving arm

stud

nut shown

in

Fig.

30.

Move stud toward

left

or right as recuired to

obt

ain

the

desired

distance

between

holes

in

button.

When

adjustment is obtained, securely ti9hten

~•uJ

nut.

SETTING 2:

(To

Increase

or

Decr,.os"

CIStanco)

(Machines with Quiok Change Mechanism)

With

needle positioned over rear hole

in

button,

move the longitudinal ad j

usti

ng lover (upper

lever),

Fig.

27A,

In

toward

the

machine until position

Is

attain

ed

where

need

le will

enter

the

forward

need

le

hole

wh

on

machine pulley

is

turned. Movement

of

the lever in toward the mochin&,

will

increase the

feed

distance;

movement

from

the

machine,

wil

l

decrease

the

diston~e.

When

correct ad,u5hnent

is

obtoinPd, the lever

can

be

locked into

position

by

tightening

tho

hex

head

screw.

t7

BUTTON CENTERED LONGITUDII'IALL Y

r

DRIVEN ARM

Fig. 29. Adju>ti

ng

Longitudinal F

..

d

Linkage

DRIVING ARM

STUD

HUT

DRIWII

Alllf

Fig.

30.

o.lvi

..

Ani

Loading...

Loading...