10.

By

aliding hinge pin with blower secured

toward front

01

rear,

as

required,

align

small

pulley

167032

on blower with Iorge blower

driving pulley

16

7022 on transmitter.

Place

tw

o collars

54

369

in

Position

1 and 2,

Fi

g. 54

firmly Oio

in

st

belt tightener brackets, os

shown

and securely tighten two set screws

465

in

each

of th

ose

collars.

11.

Assemble bolt

tens

ion brocket

167020

to

••·

tension

167239

with two screws 1

40548.

12.

P la

ce

blower drivi

ng

belt

167019

in belt

grooves of blower driving pulley

1670

22

and

blower pulley

167032.

13. Ins

ta

ll

te

nsion

brocket and

its

extension

on

blower,

as

shown

usin

g two

sc

r

ews

199.

14. The lower

saew

199

octo

as

o pivot; upper

screw 199 permits ad

ju

stment. Before lighten-

ing

these two screws

sw

in

g tension brockot

167020

un

til

its

b

ump

er

A is in line with

IOJgt

head

of

scf'ew 8 on tron$miHer. Tighten two

sc

rews

199.

15.

Loo

se

n two screws

140548

and

adjust

length

of

brock

et

assembly to obtain correct tension

of blower

dri

ving belt

167019.

Securely tighten

two

screws

140548.

16.

I

nstall

elbow

167244

and wosto·throad

col·

lector

167025,

as

shown.

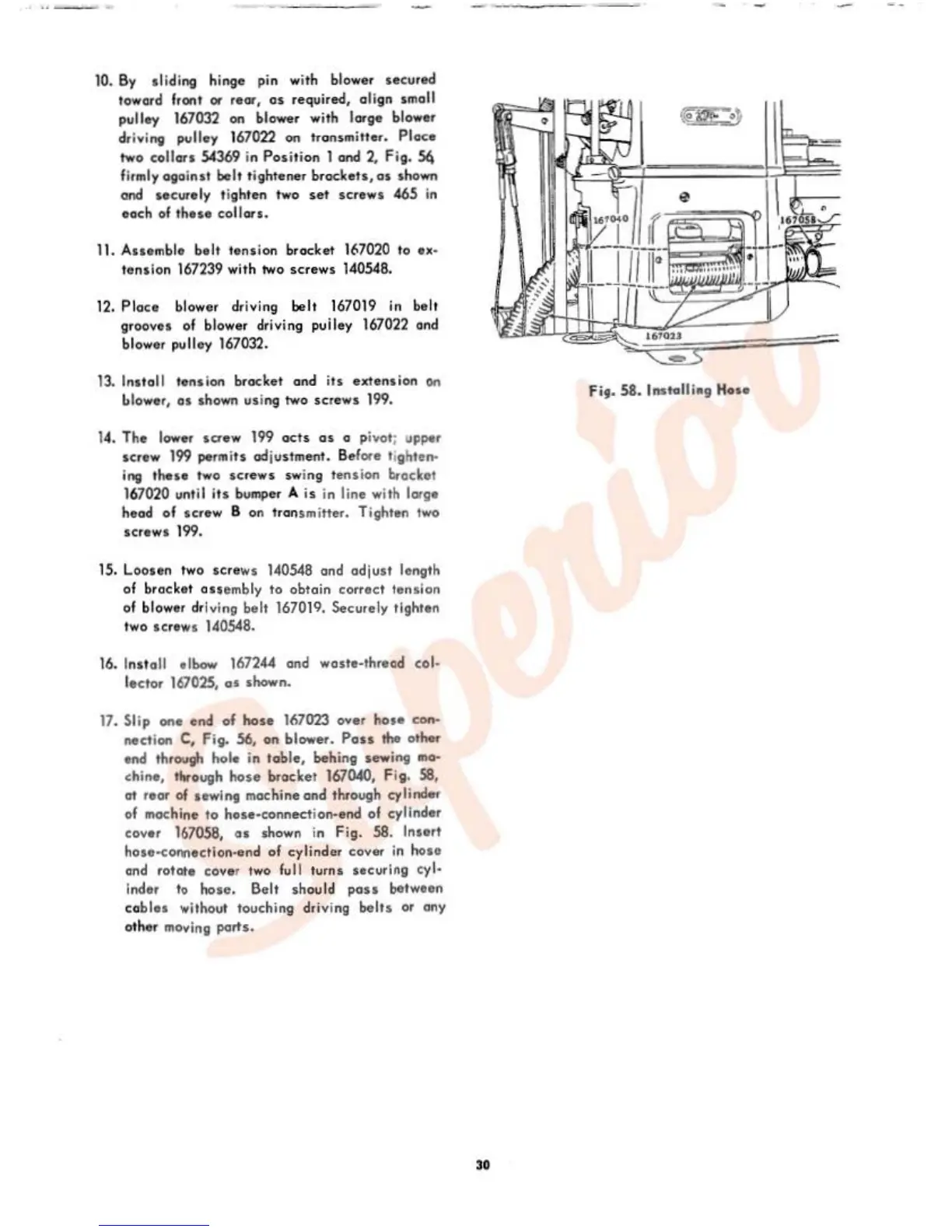

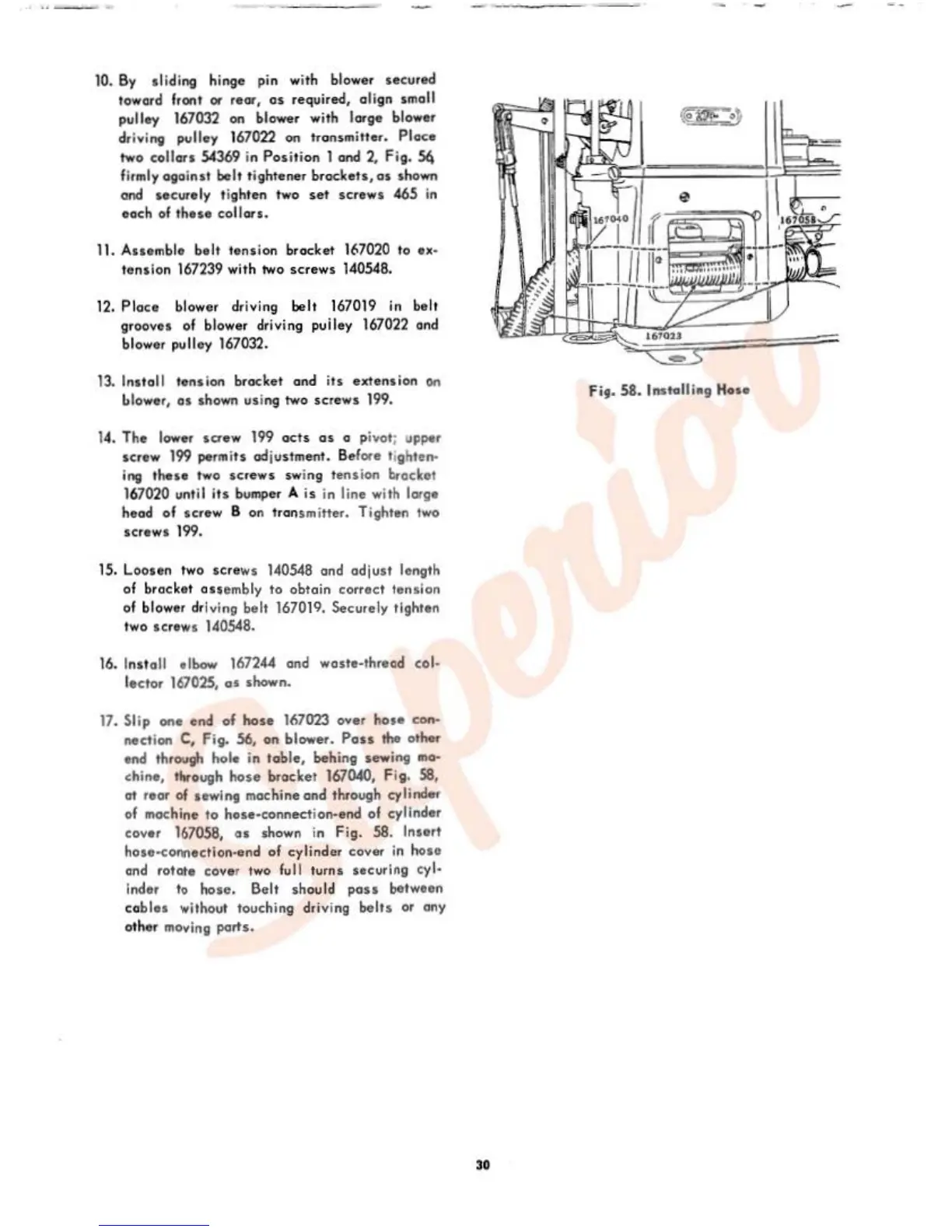

17.

Sl

ip

ont

end

of

hose

167023

over

host

con·

nection

C,

Fig. 56, on blower.

Pass

the

otho.

ond throuvh hole in table, behing sewing

ono-

chine, through

hose

brocket 167040, Fig. 58,

at

roar

of

sowing machine

and

through cylinder

of mochine

to

hose-connec;ti

on--end

of cylinder

covtr

167058,

as

shown in

Fig.

58. Insert

hose-c:omection·ond

of

c-y

linder cover in

hoso

and

rotate cover two full turns securing

cy

l•

inder

to

hose. Belt shou

ld

pass

between

cabl

es

without touching driving

belts

or

any

other moving ports.

fi9

.

58.

lnstalliog

Hose

30

Loading...

Loading...