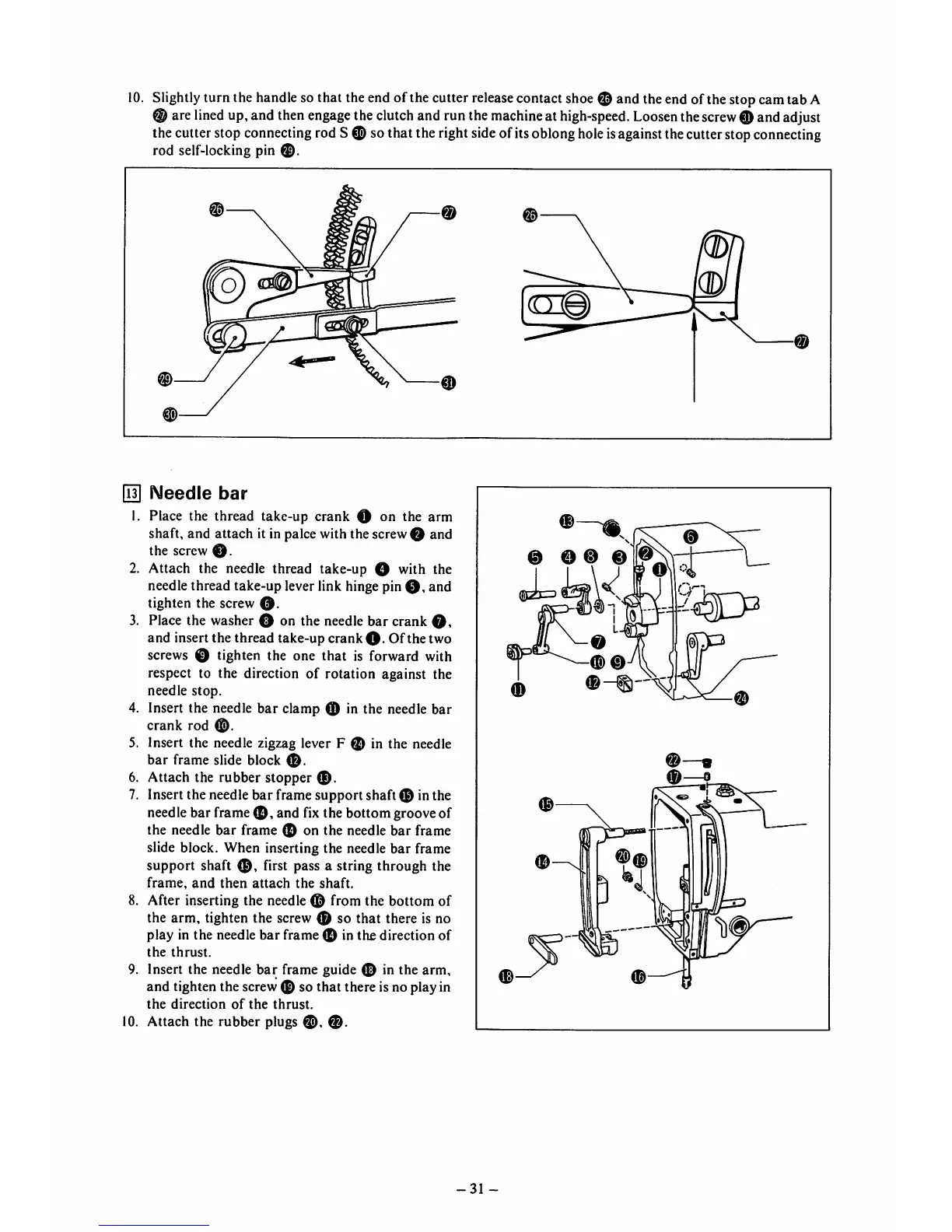

10.

Slightly turn the

handle

so that theendof the cutter

release

contactshoe© and theend ofthestop camtab A

® are

lined

up,and

then

engage

the

clutch

andrunthe

machine

at

high-speed.

Loosen

the

screw

0 and

adjust

thecutterstop

connecting

rodS 0 sothat the rightsideofits

oblong

hole

is

against

thecutterstop

connecting

rod self-locking pin

0.

m

0

0

[la]

Needle

bar

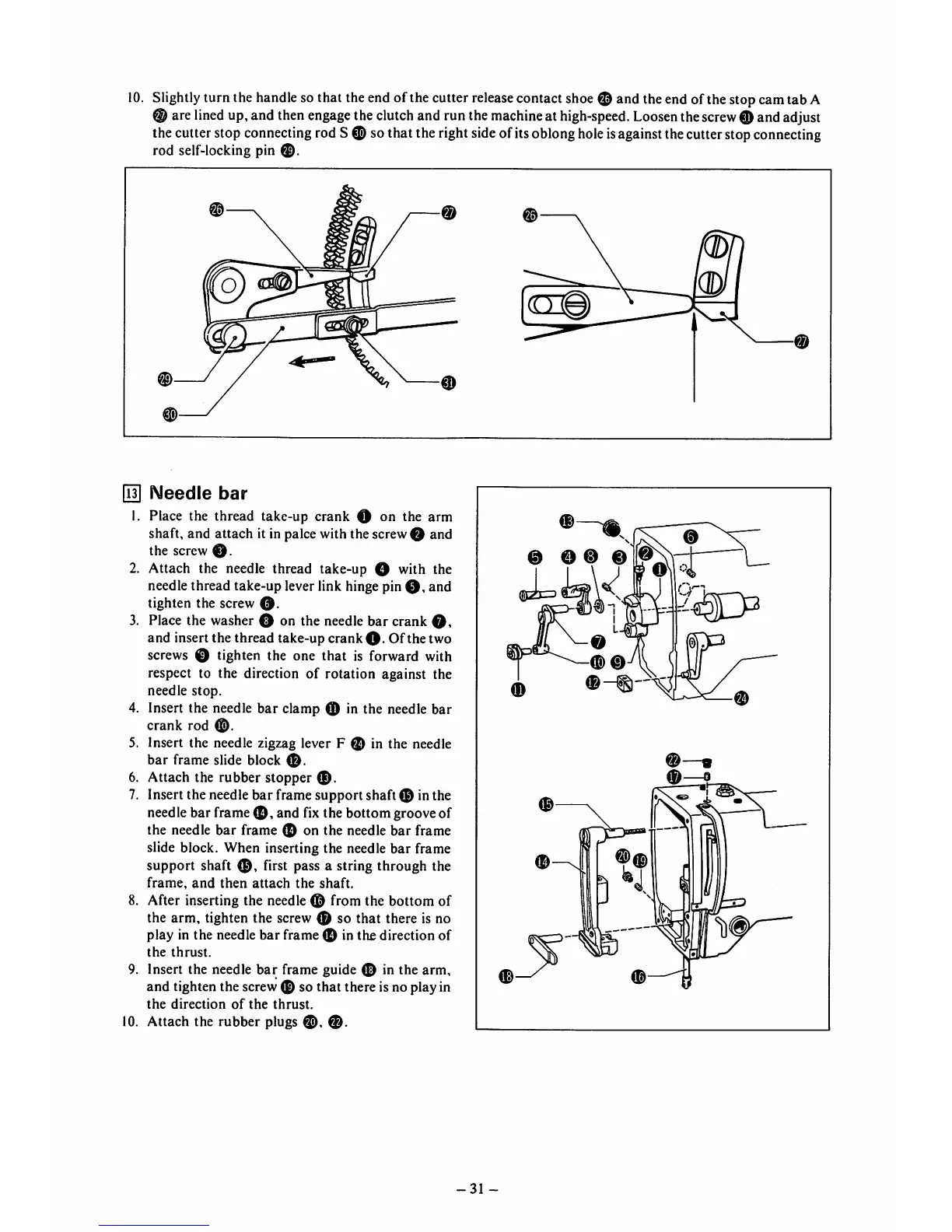

1. Place the thread take-up crank O on the arm

shaft, and attach it in palce with the screw O and

the screw

0.

2. Attach the needle thread take-up O with the

needle thread take-up lever link hinge pin

0,

and

tighten the screw

0.

3. Place the washer 0 on the needle bar crank

0,

and insert the thread take-up crank

0.

Of the two

screws 0 tighten the one that is forward with

respect to the direction of rotation against the

needle

stop.

4. Insert the needle

bar

clamp 0 in the needle bar

crank

rod

5. Insert the needle zigzag lever F 0 in the needle

bar

frame

slide

block

6. Attach the rubber stopper

0.

7. Insert the needle

bar

frame support shaft 0 in the

needlebar frame 0 , and fix the bottom grooveof

the needle

bar

frame 0 on the needle

bar

frame

slide block. When inserting the needle bar frame

support shaft

0,

first pass a string through the

frame,

and

then

attach

the

shaft.

8. After inserting the needle 0 from the

bottom

of

the arm, tighten the screw 0 so that there is no

play in the needle

bar

frame 0 in

the

direction

of

the

thrust.

9. Insert the needle

bar

frame guide 0 in the arm,

and tighten the screw0 so that there is no playin

the

direction

of

the

thrust.

10. Attach the rubber plugs

0,

0.

31

-

0 0 0 0

(swL

0—®

0

Loading...

Loading...