Page 17 of 42

6. Fault finding

Prior to repairing the appliance it is necessary to reduce the pressure of the

air in the air chamber to zero and disconnect the appliance from the mains

supply.

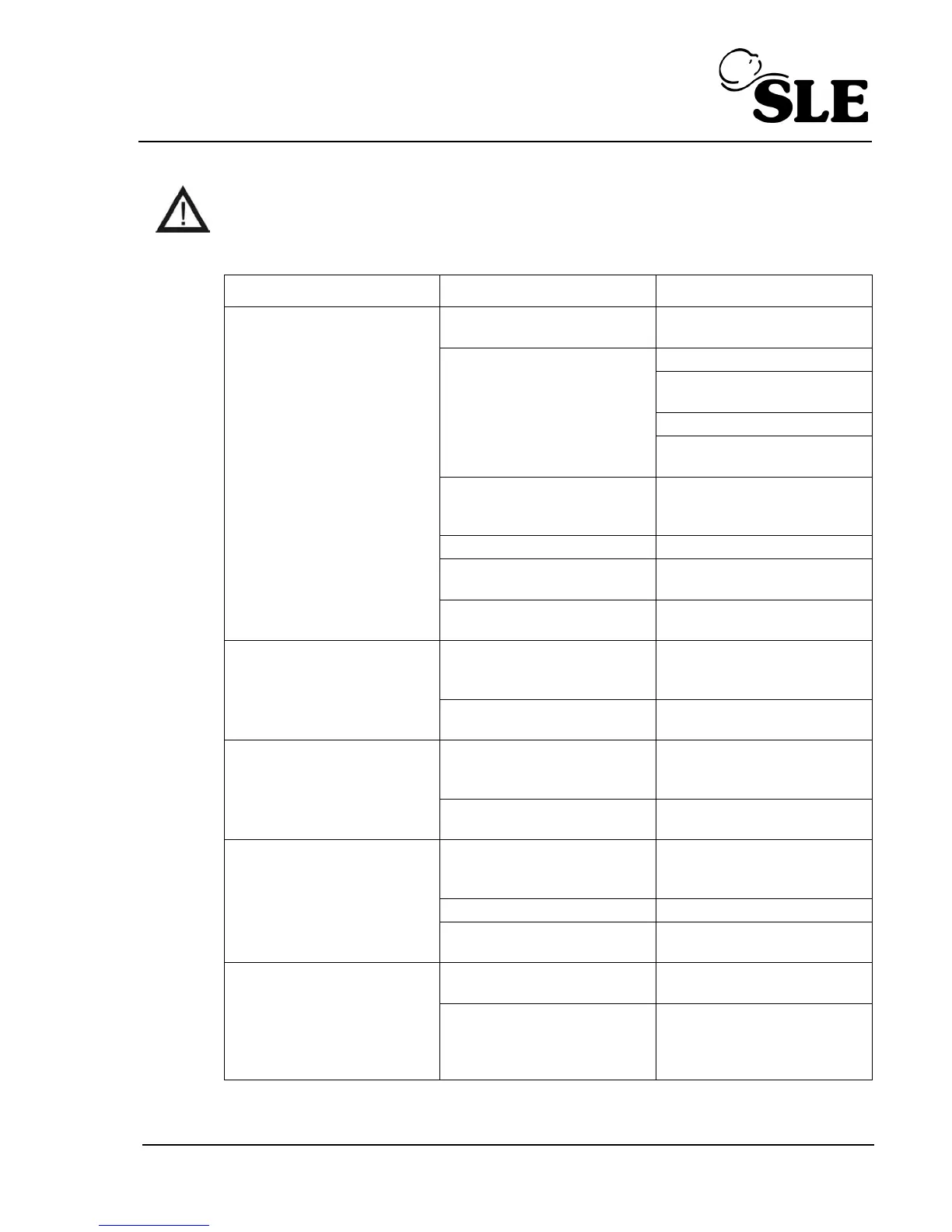

Failure

Possible Cause Troubleshooting

Compressor does not start

No mains voltage Switched off mains breaker in

distribution system

No current in pressure switch Check Supply

Fuse Blown – replace the

defective fuse

Loose wire terminal – tighten

Power cord defective – replace

power cord

Interrupted winding of motor,

damaged

thermal protection

Replace motor

Defective capacitor Replace capacitor

Jammed piston or another

rotary part

Replace damaged parts

Pressure switch does not switch

on

Change pressure switch

The pointer of humidity indicator

is out of green zone

Leakage of air from pneumatic

distribution system

Control of pneumatic

distribution system – seal loose

connection

Large consumption of com-

pressed air

Do not exceed max. flow

Compressor often

switches on

Leakage of air from pneumatic

distribution system

Control of pneumatic

distribution system – seal loose

connection

Leakage of check valve Clean check valve, replace

sealing, replace check valve

The operation of

compressor is extended

Leakage of air from pneumatic

distribution system

Control of pneumatic

distribution system – seal loose

connection

Worn-out piston rings Replace worn-out piston rings

Dirty Filters Replace the dirty filter with new

ones

Red indicator lights – state of

overheating

Dirty inlet filters Replace the dirty filter with new

ones

High ambient temperature of air

Cooling fans don’t work

Ensure suitable conditions of

the environment

Replace faulty fans

Replace faulty thermo -switch

Loading...

Loading...