Page 23 of 42

8.4 Cleaning and replacement of inlet filter

In the front of the cabinet, there is an inlet filter. The Inlet filter must be replaced/

cleaned according to the environment where the compressor is used.

When replacing/cleaning, it is necessary to pull out the inlet filter. Replace the filter

for a new one or wash the filter if dirty.

When assembling, reverse this procedure.

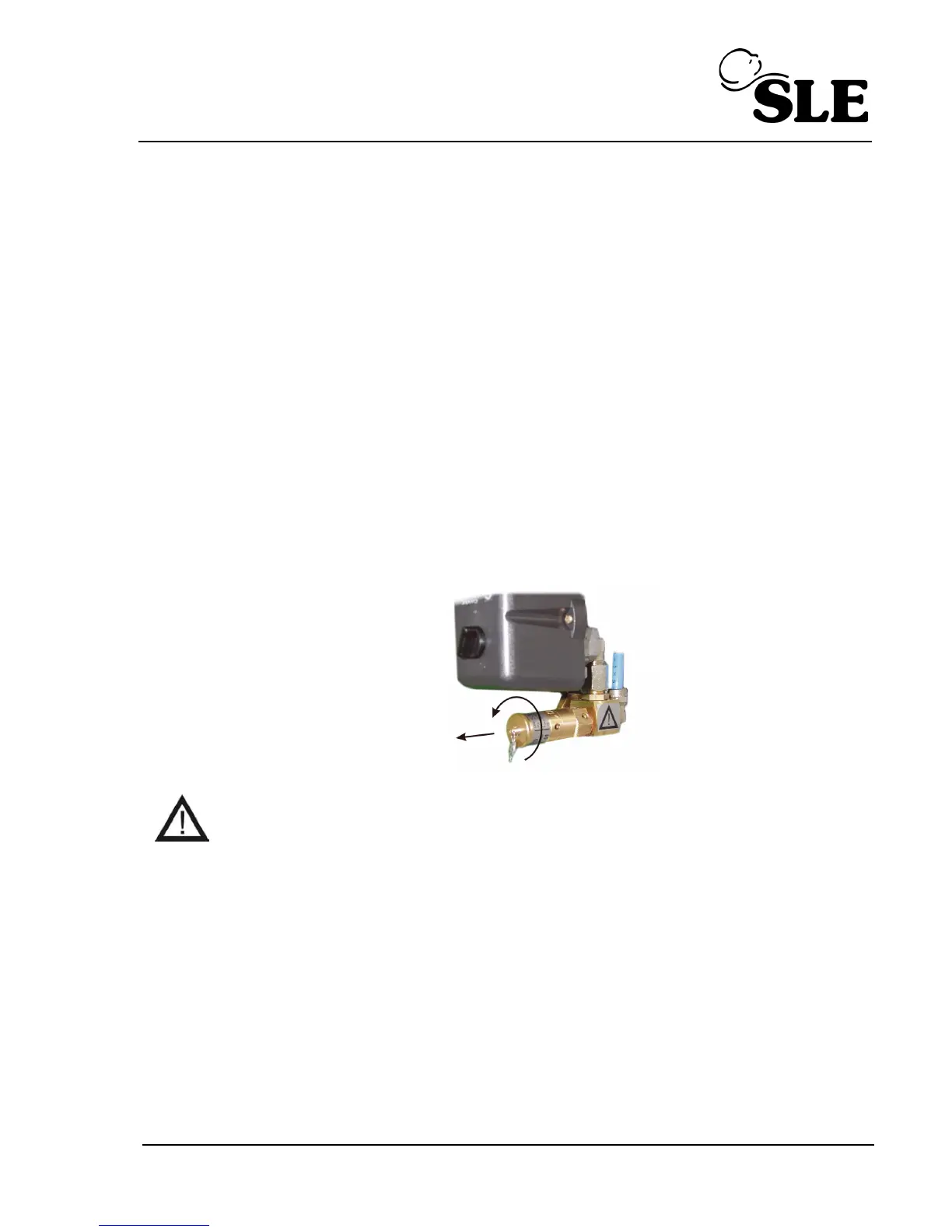

8.5 Check of safety valve

The safety valve is adjusted to 8 bars by the manufacturer, tested

and marked. It must not be readjusted.

• Turn the screw of the safety valve several rotations to left until safety valve puffs.

• Let safety valve puff freely only for a short period of time.

• Turn screw to the right until the limit is reached, the valve must be now be closed.

The safety valve must not be used for depressurizing the pressure tank. It

could endanger the function of the safety valve.

Loading...

Loading...