HRX-OM-I051

Chapter 8 Appendix

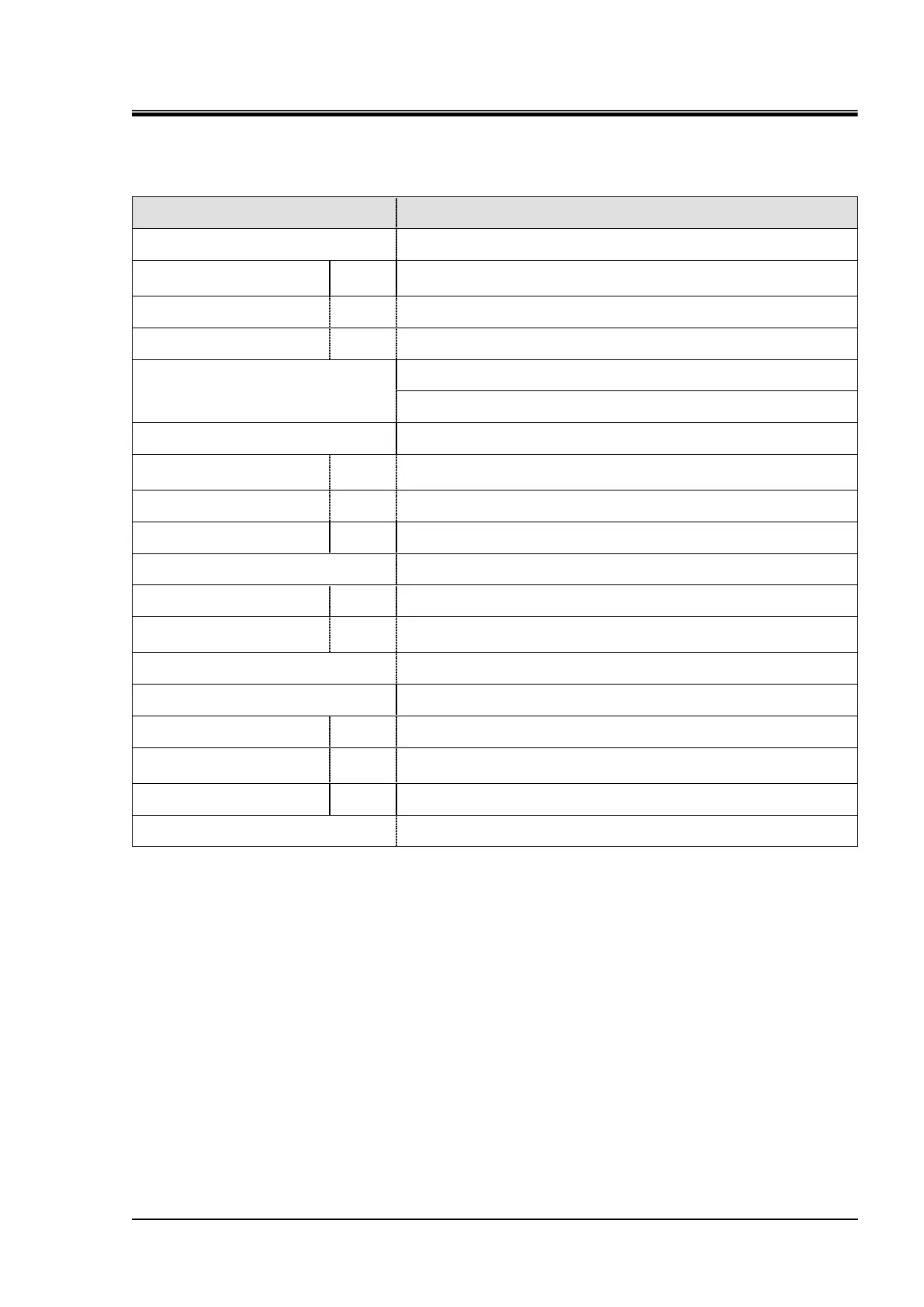

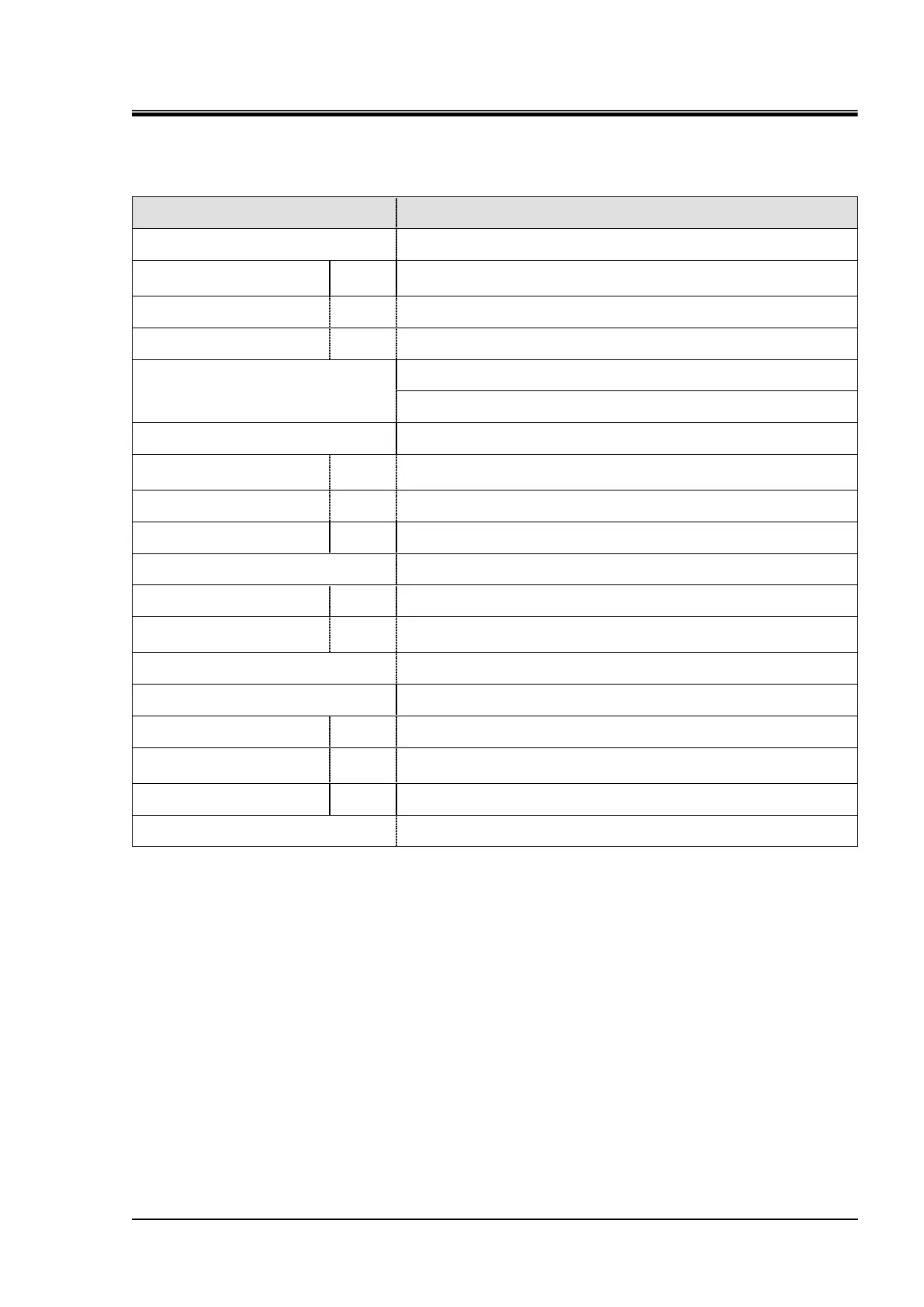

HRZ Series 8.1 Specification

Specification for ethylene glycol solution (low temperature with Inverter)

Table 8-9 Specification for ethylene glycol solution (low temperature with Inverter)

Cooling capacity

*1

(50Hz/60Hz)

Operating temperature range

Ethylene glycol aqueous solution 60%

*3

(No intrusion of foreign body)

R404A(HFC) (CFC Free),

(GWP:3922)

Pump capacity

*4

(50Hz/60Hz)

Max. 0.40 (At 20L/min)

(58[PSIG] At 5.3gal/min) with flow control function by VFD

10 to 30 / 0.3 to 0.7 (45 to 100 [PSIG])

Required flow of facility water

*9

(50Hz/60Hz)

3-phase 50/60Hz AC200/200 to 208V±10%

W380D870H950

(W14.96xD34.25xH37.40[inch])

Serial RS-485 (Dsub-9pin) , Contact signal (Dsub-25pin)

*1: The capacity is derived under the conditions that the facility water temp. is 25°C and that the circulating fluid flow

rate is obtained at a specified flow rate of pump capacity. Applied to 50 / 60Hz.

*2: This is a system output temperature, with flow rate defined in pump capacity secured, when stabilized with no

disturbance. Its upper limit may be violated if an insufficient amount of the circulating fluid is present or a

disturbance to flow rate is observed.

*3: Pure ethylene glycol needs dilution with fresh water before use.

Ethylene glycol with additives such as preservatives is NOT available.

*4: The capacity is derived at the Outlet of this system when the circulating fluid temp. is at 20°C.

*5: This is a minimum amount of the fluid for operation of the Thermo Chiller outfitted with internal piping and heat

exchanger in this system. Circulating fluid temp.: 20°C

*6: This is an auxiliary space with a main tank capacity excluded. Available for circulating fluid recovery from external

piping and backup supply.

*7: This is the dimensions of panels, which is derived without protrusions such as a breaker handle.

*8: This is the mass of the system when it contains no circulating fluid.

*9: Facility water temp. is 25°C. There is required flow when adding load described on cooling capacity.

Loading...

Loading...