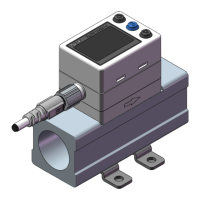

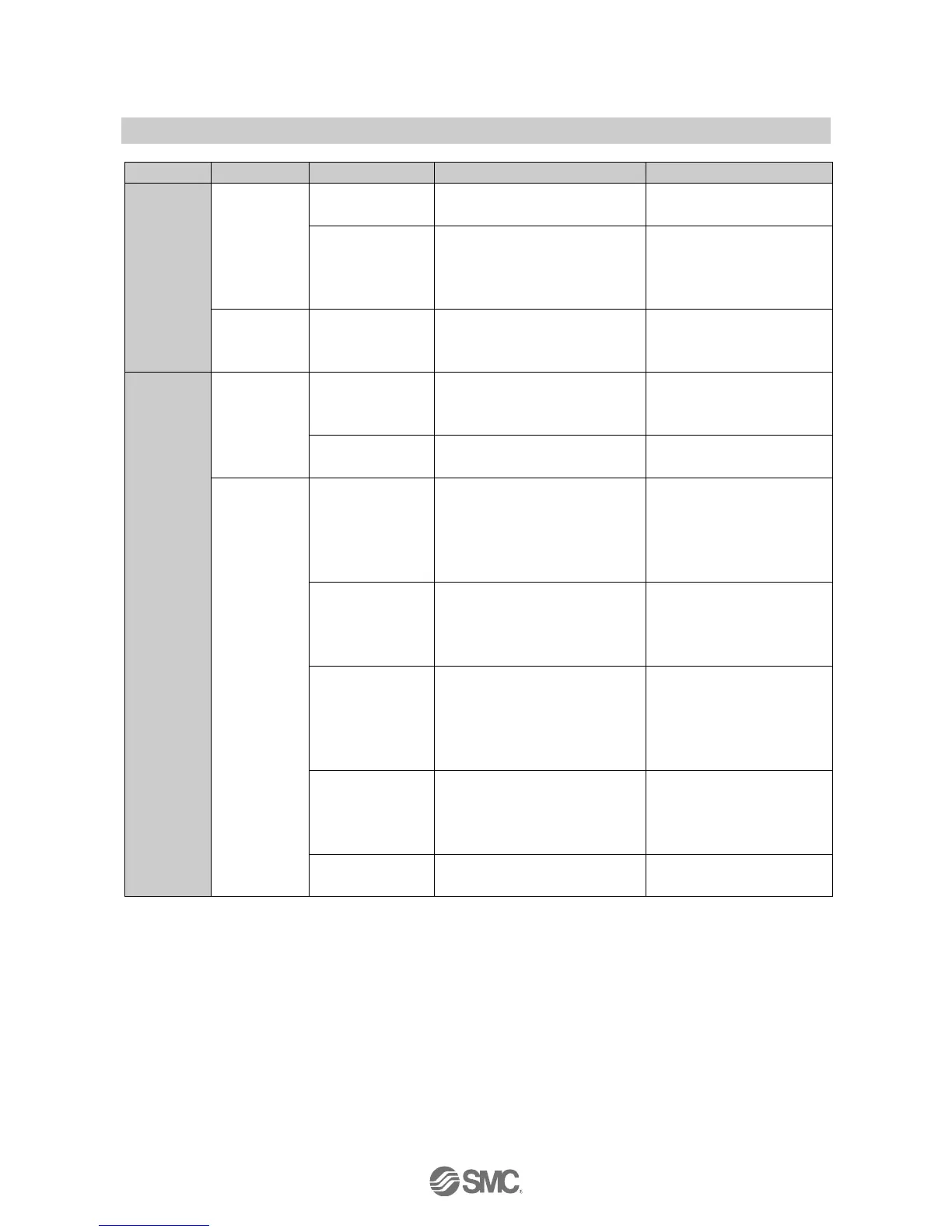

Incorrect flow

range selected

Check the flow range of the model

used.

Select a model with the

appropriate flow range.

Check for air leakage due to loose

piping or insufficient sealant, etc.

Reconnect the piping with the

specified tightening torque

and re-apply the sealant

tape.

The flow

adjustment valve

is closed

Check the flow adjustment valve.

Open the flow adjustment

valve and adjust the flow.

Check that the brown, blue, black

and white wires are connected

correctly.

Connector is

disconnected

Correct the connector wiring.

Foreign matter has

entered the flow

passage or

adhered to the

sensor

(1) Check if any foreign matter

has entered the flow passage.

(2) Check if there is foreign matter

on the mesh.

Install a filter or mist

separator on the IN side.

Piping in the

reverse direction

Check that the fluid flow is in the

same direction as marked on the

product body.

Ensure the product is

mounted so that the fluid flow

matches the direction marked

on the product body.

Check if there is any supply

pressure fluctuation or pressure

pulsation due to the

characteristics of the source

compressor (or pump).

Install an accumulator tank to

reduce the pressure

fluctuation.

Change the pressure source

to one that has less pulsation.

Check for air leakage due to loose

piping or insufficient sealant, etc.

Reconnect the piping with the

specified tightening torque

and re-apply the sealant

tape.

Check the hysteresis set value.

Increase the hysteresis set

value.

Loading...

Loading...