-21-

No. ZK2-OM00201

■Application and Operating Pressure Range

Ejector system Vacuum pump system

■Precautions

1. Insertion of the tube

(1) Cut the tube perpendicularly, being careful not to damage the external surface. Use SMC’s tube cutter

TK-1, 2 or 3 for cutting. Do not cut the tube with pliers, nippers, scissors, etc. If the tube is cut by any tools

other than a tube cutter, the cut surface of the tube will be slanted or flat, making it difficult to be connected

securely, causing the tube to come off or air leakage after the tube is connected. Also, allow a sufficient

margin of tube length.

(2) Hold the tube and push it in slowly, inserting it securely all the way into the fitting.

(3) After inserting the tubing, pull on it gently to confirm that it will not come out. If it is not installed securely all

the way into the fitting, problems such as leakage or disconnection of the tube can occur.

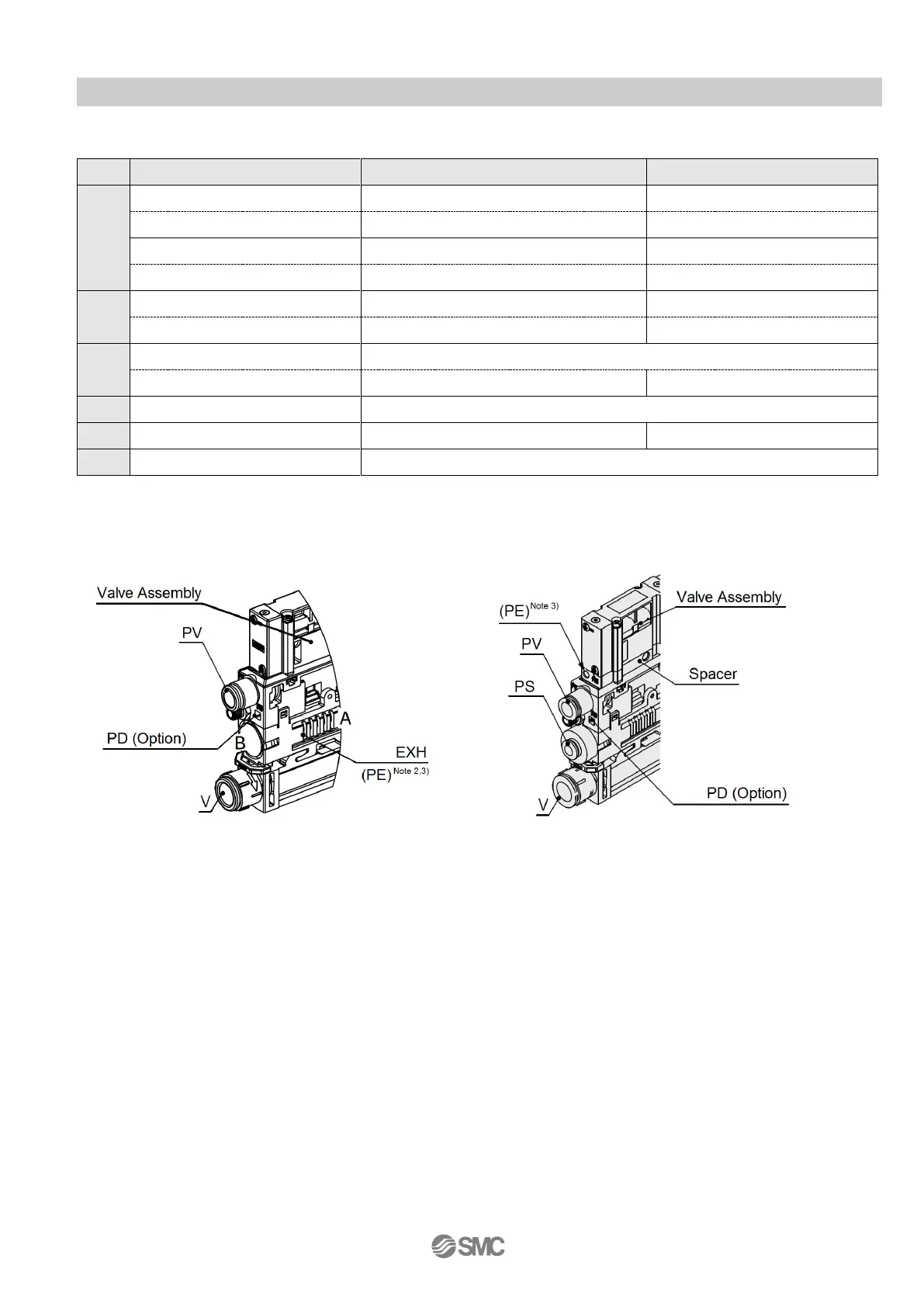

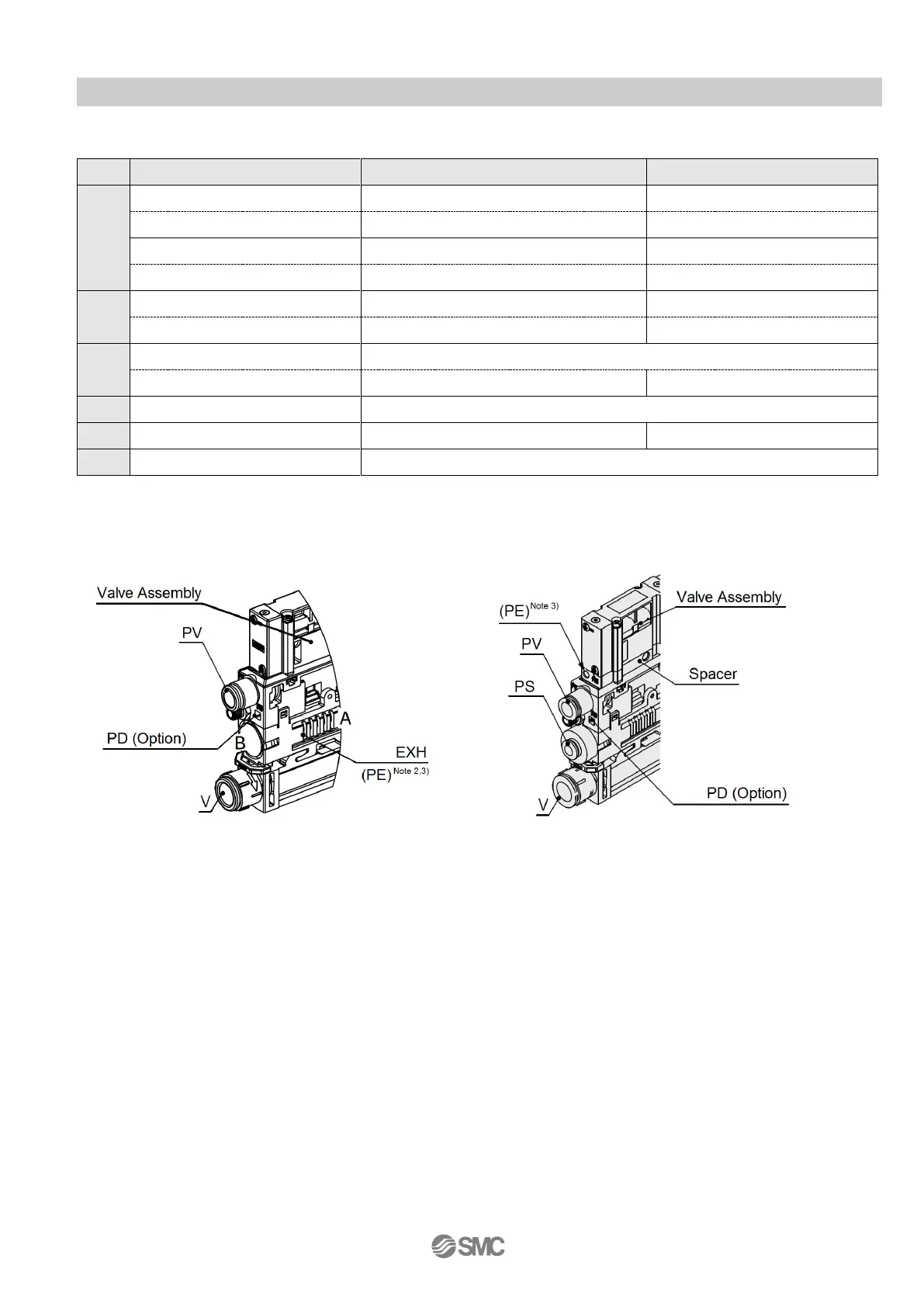

Compressed air supply for operating ejector

(Operating pressure range)

Vacuum pressure supply port

Vacuum source (vacuum pump)

(Operating pressure range)

Pilot pressure supply port

Compressed air supply for pilot valve

(Operating pressure range)

Individual release pressure supply port

Release pressure, Compressed air supply for individual setting (Option)

(Operating pressure range)

For connecting adsorption equipment including pad

Exhaust when ejector operates

Note 2)

Pilot pressure exhaust port

Exhaust when valve operates

Note 3)

Note 1) For models without valve, pressure can be 0.3 MPa or less.

Note 2) For ejectors with silencer, air exhausts from A (slit on both sides). For port exhaust type, air exhausts from B.

Note 3) Pilot pressure for ejectors is exhausted from the ejector and the common exhaust. Vacuum pump system exhausts air from

PE port on the spacer. (Female thread type (M3) is available by option “C” for PE port of the pump system.)

Loading...

Loading...