Use and maintenance manual FP560 - FP560A - FP870A

25

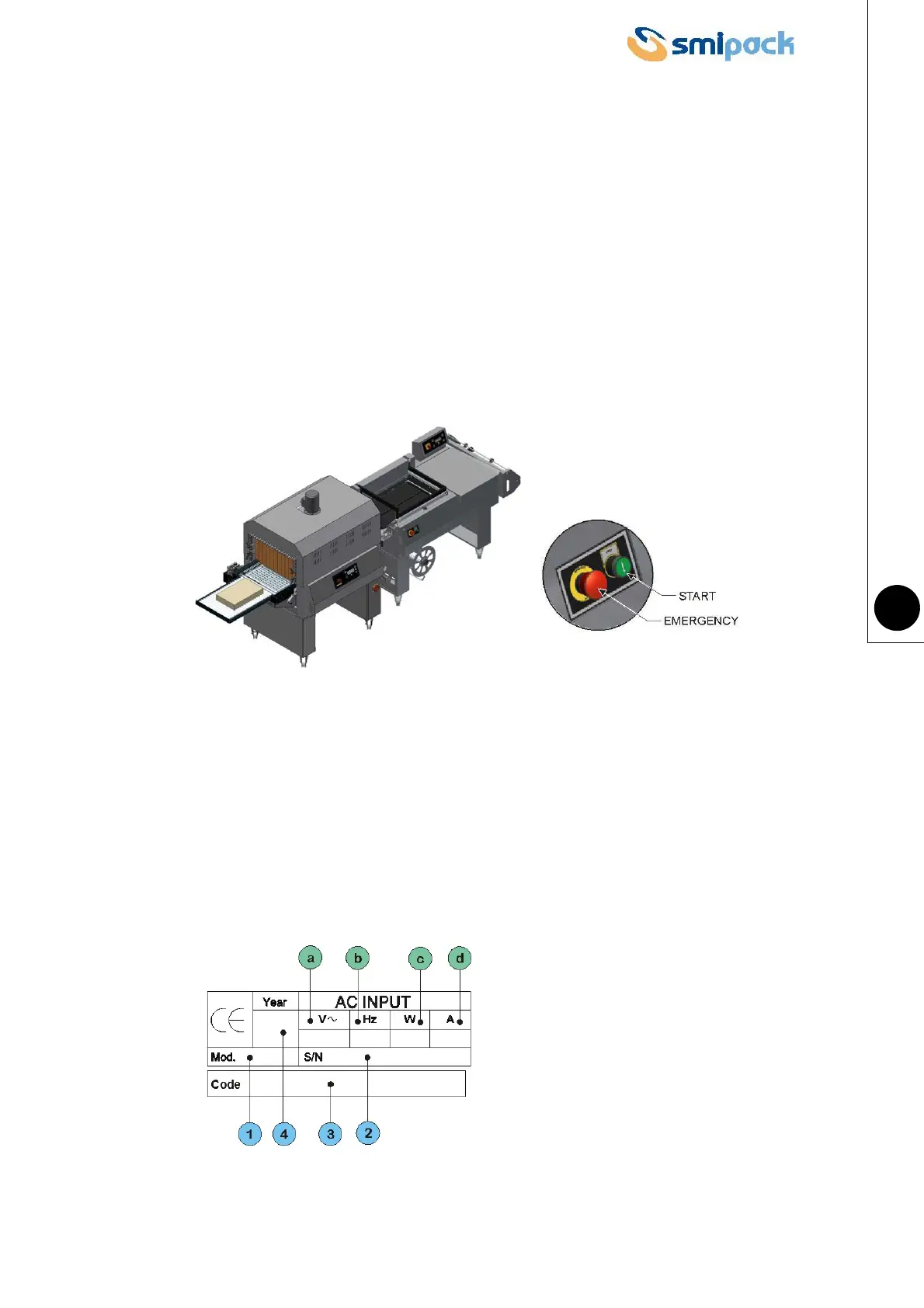

3.3 AUTOMATED OPERATION OF MACHINES

The FP560A - FP870A models have an automated system which, when the START button is

pressed, makes it possible to close the sealing frame. At the end of the sealing cycle, the

sealing frame returns automatically and independently to its starting position, while the product

is transported out of the area.

During the initial work phase, a motor controls the descent and ascent of the frame. Press any

button on the operator panel to stop the packaging cycle.

The software enables electronic control of the operating times of the frame and modification of

the sealing pressure. The final phase, "product evacuation", involves the use of a conveyor belt

that does not require the intervention of the operator. This automatism reduces the packaging

cycle time and increases the hourly productivity.

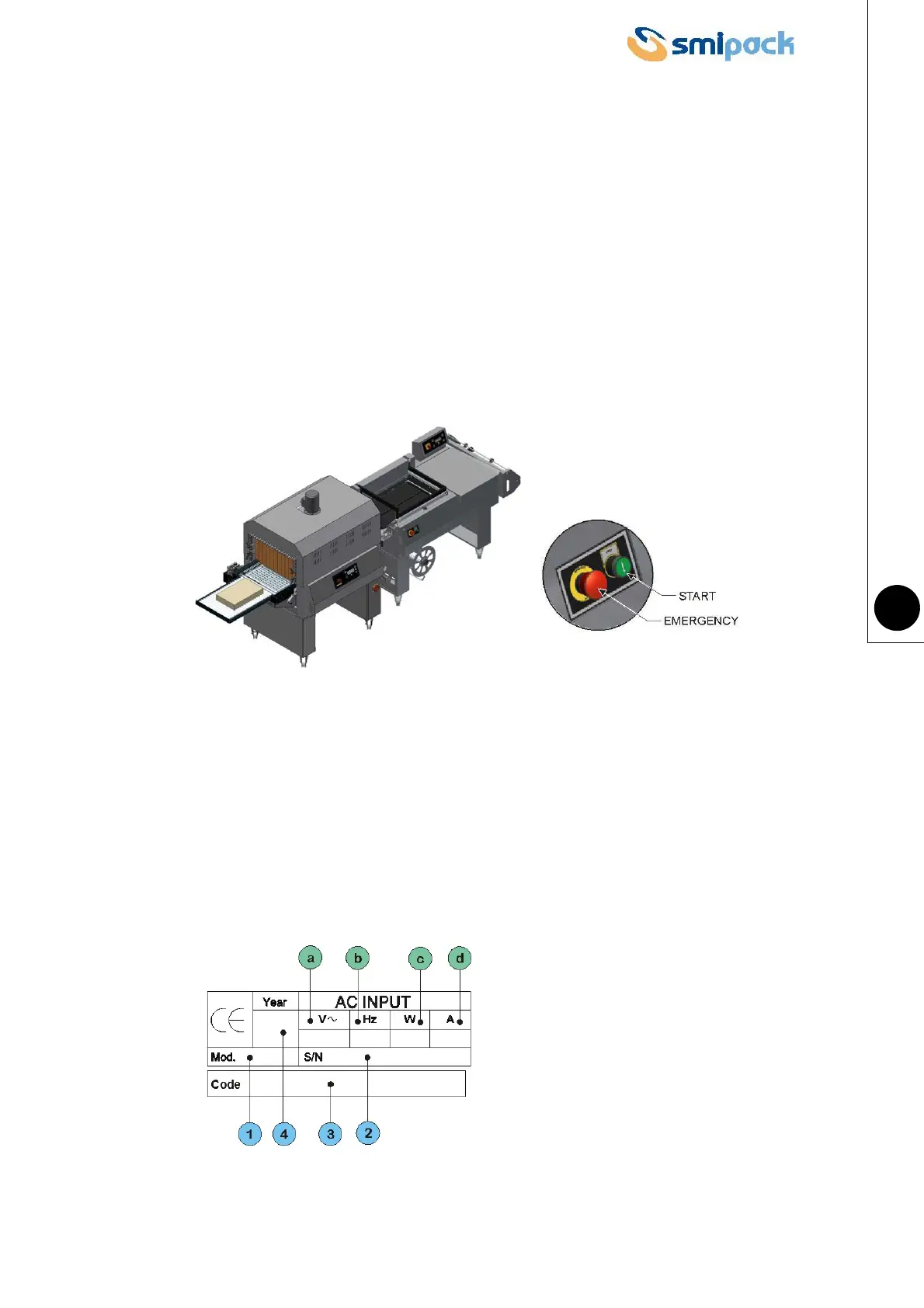

3.4 IDENTIFICATION DATA AND TECHNICAL DATA OF THE

MACHINE

Each machine is provided with a plate where it is easy to recover data which must be

communicated to the manufacturer in case of problems or when requesting spare parts etc.

(ref. 1-2-3-4). This plate also carries electrical technical data for installation of the machine (ref.

a-b-c-d).

1 - Model

2 - Serial number

3 - Machine code

4 - Year of manufacture

a - Nominal voltage

b - Nominal frequency

c - Nominal power

d - Nominal current

ATTENTION! Before performing connections to the electrical mains, make sure that the power

supply voltage is compatible with that shown on the plate.

Loading...

Loading...