14

BOC Smootharc 180 Multiprocess operating manual

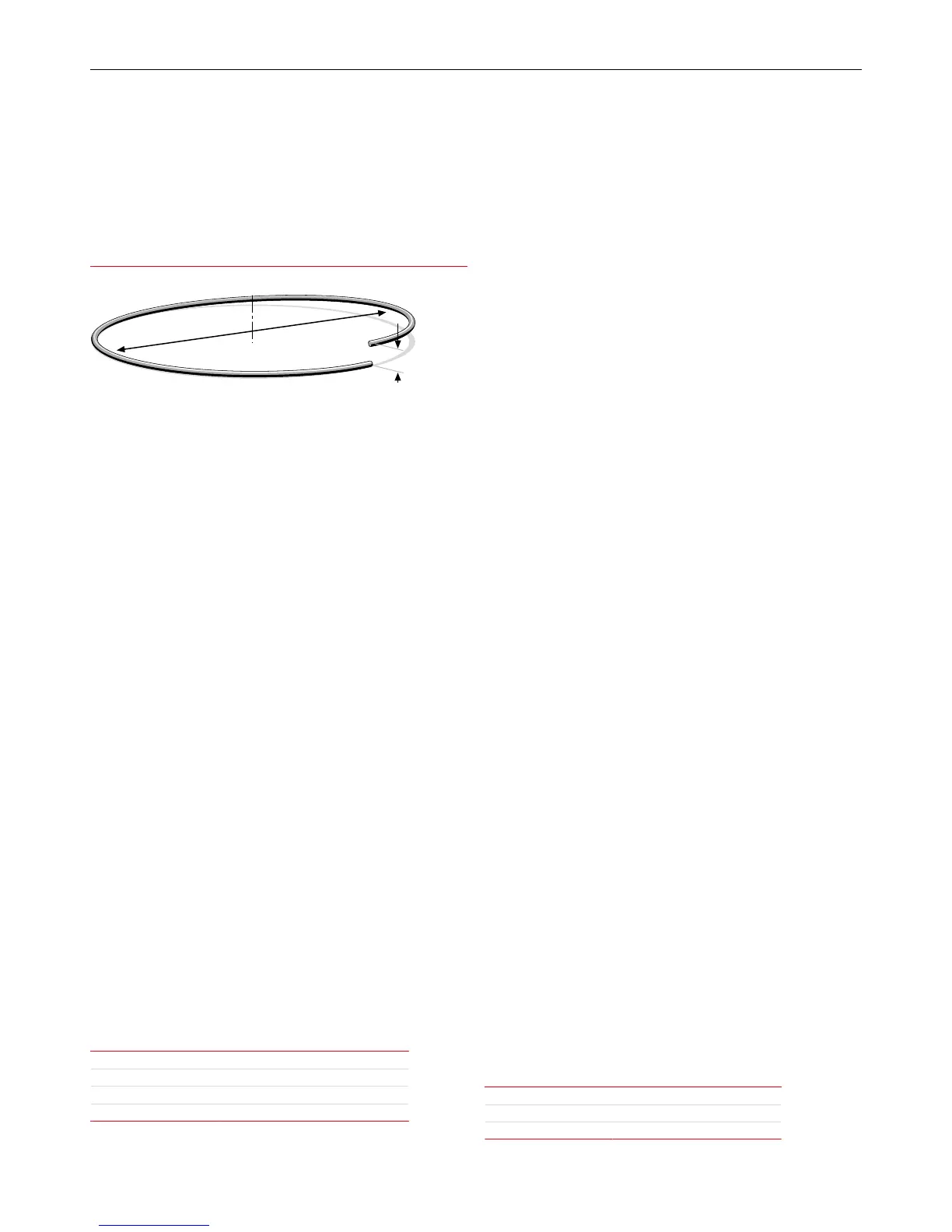

Cast

Helix

Cast – Diameter of the circle

Helix – Vertical height

Cast and Helix

black residue is found on the cloth the surface of the wire is not properly

cleaned.

Cast and Helix

The cast and helix of the wire has a major inuence on the feedability of

MIG/MAG wire.

If the cast is too large the wire will move in an upward direction from the

tip when welding and if too small the wire will dip down from the tip.

The result of this is excessive tip wear and increased wear in the liners.

If the helix is too large the wire will leave the tip with a corkscrew eect.

Selection of the Correct Power Source

Power sources for MIG/MAG welding is selected on a number of dierent

criteria, including:

1 Maximum output of the machine

2 Duty cycle

3 Output control (voltage selection, wire feed speed control)

4 Portability

The following table gives an indication of the operating amperage for

dierent size wires.

Wire Size Amperage Range (A)

0.8 mm 60–180

0.9 mm 70–250

1.0 mm 90–280

1.2 mm 120–340

Selection of the Correct Polarity on the Power Source

Many power sources are tted with an optional reverse polarity dinse

connector.

To achieve the optimum welding it is important to adhere to the

consumable manufacturer's instruction to select the polarity.

As a general rule all solid and metal cored wires are welded on electrode

positive. (Work return lead tted to the negative connector.)

Some grades of self shielded ux cored wires (i.e. E71T-11, E71T-GS etc)

needs to be welded on electrode negative. (Work return lead tted to

the positive connector.)

Selection of the Correct Shielding Gas

The selection of the shielding gas has a direct inuence on the

appearance and quality of the weldbead.

The thickness of the material to be welded will determine the type of

shielding gas that has to be selected. As a general rule the thicker the

material (C-Mn and Alloy steels) are the higher the percentage of CO

2

in

the shielding gas mixture.

Dierent grades of shielding are required for materials such as stainless

steel, aluminium and copper.

The following table gives an indication of the most common shielding

gases used for Carbon Manganese and alloy steel.

Material thickness Recommended shielding gas

1–8 mm Argoshield Light

5–12 mm Argoshield Universal

>12 mm Argoshield Heavy

Loading...

Loading...