38

BOC Smootharc 180 Multiprocess operating manual

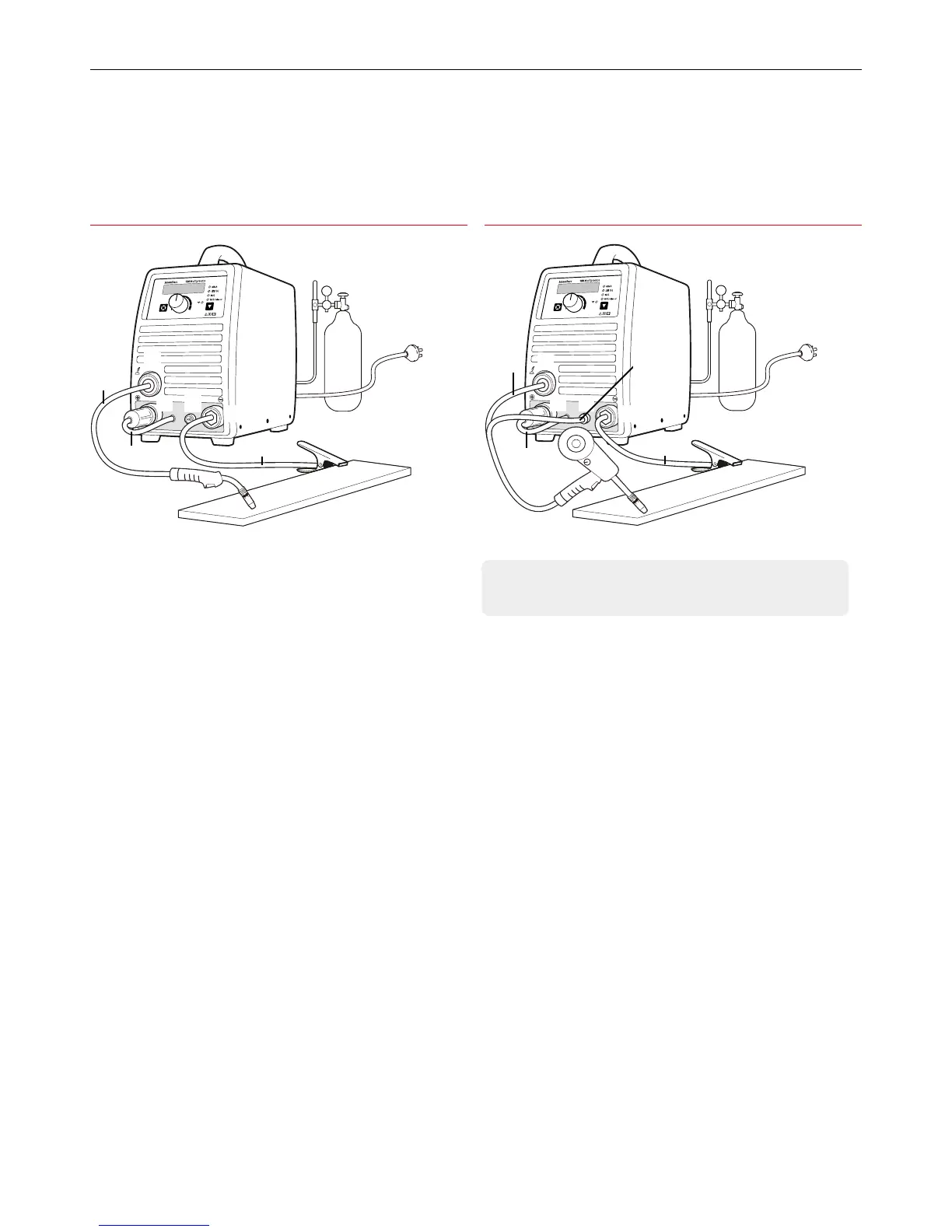

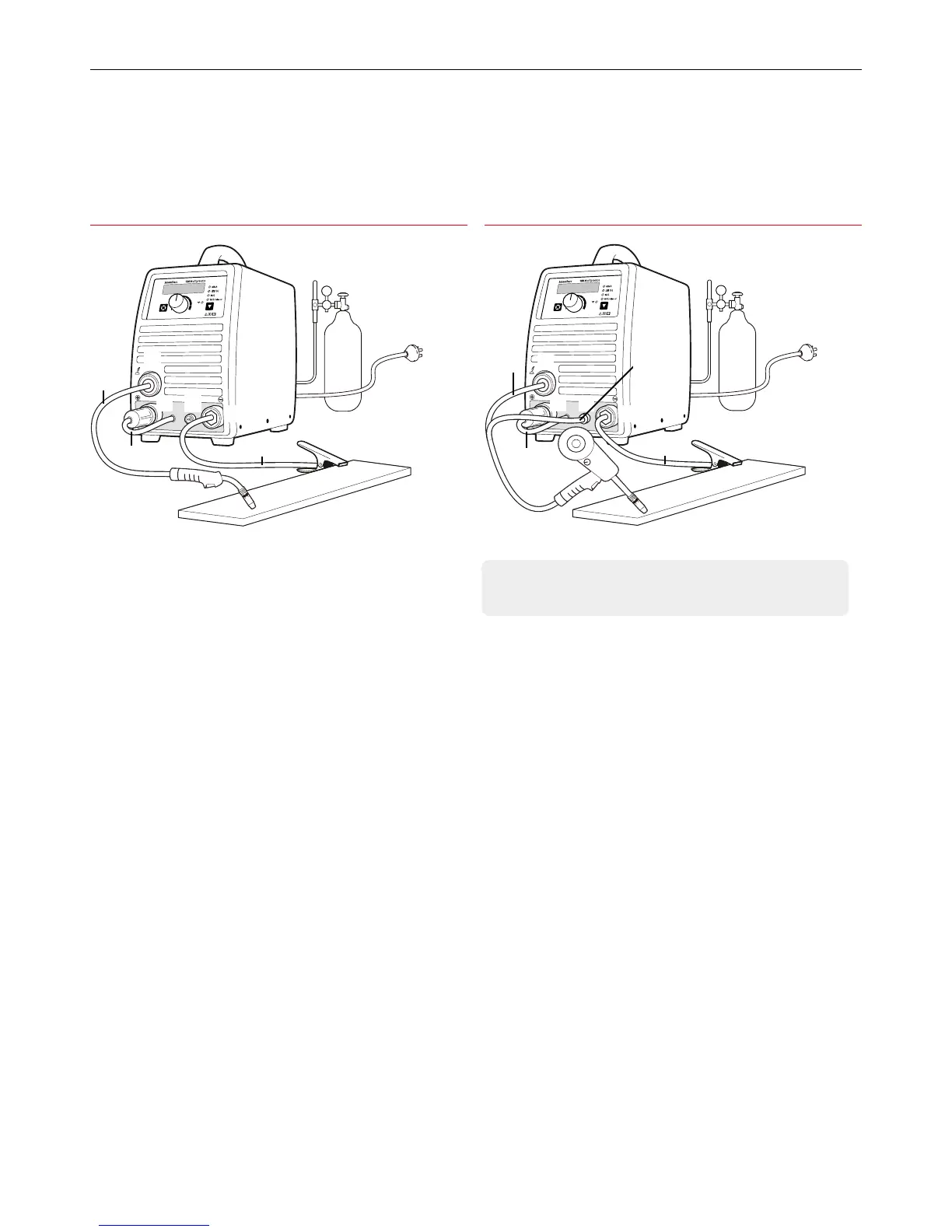

Installation for MIG/MAG process Installation for MIG/MAG set up with OPTIONAL spool gun

8.1 Installation for MIG/MAG process

1 Connect the gas cylinder to the regulator. Select correct shielding gas

for the application.

2 Fit the wire spool to the machine. Select correct welding wire for

application.

3 Select the appropriate feed roller to suit the wire being used

- This machine comes complete with two types of wire feed rollers

- V groove for use with solid carbon manganese and stainless steels

- U groove for use with soft wires such as aluminium

4 Loosen the wire feed tension screws and insert the wire. Ret and

tension rollers ensuring the wire is gripped suciently so as not

to slip but avoid over tightening as this can aect feed quality and

cause wire feed components to wear rapidly.

5 Fit and tighten the A torch on the 10 euro output connection. Ensure

correct torch liner and contact tip are selected.

6 Select the correct polarity for the type of wire used as indicated on

the consumable packaging. This is achieved by swapping the polarity

terminal wires. For most solid wires the terminal should be set as

torch positive.

7 For torch positive, plug the 12 short mechanical connector (link

plug) on the front panel into the 11 positive (+) terminal and the

Bwork return lead into the 14 negative (-) terminal.

8 For torch negative, plug the 12 short mechanical connector (link

plug) into the 14 negative (-) terminal, and the B work return lead

into the 11 positive (+) terminal.

8.2 Installation for MIG/MAG set up

with OPTIONAL spool gun

1 Connect the gas cylinder to the regulator. Select correct shielding gas

for the application.

2 Plug S1 spool gun euro connection into 10 euro output connection.

3 Plug S2 spool gun control cable into 13 control connection.

4 Fit wire spool to the spool gun

- Lift cover up

- Remove retaining screw by turning clockwise.

- Slide mini spool in

- Adjust spool tension using knurled ring on the spool shaft

- Feed wire through front of the torch

- Close cover

5 Select the correct polarity for the type of wire used as indicated on

the consumable packaging. This is achieved by swapping the polarity

terminal wires. For most solid wires the terminal should be set as

torch positive.

6 For torch positive, plug the 12 short mechanical connector (link

plug) on the front panel into the 11 positive (+) terminal and the

Bwork return lead into the 14 negative (-) terminal.

7 For torch negative, plug the 12 short mechanical connector (link

plug) into the 14 negative (-) terminal , and the B work return lead

into the 11 positive (+) terminal.

8 Turn machine on.

9 The 4 Spool gun indicator light will illuminate. (Please note MIG

Pulse Al function is not avaliable with the spool gun).

10 Please note wire feed speed is only active from the spool gun .

11 The MIG spool gun only takes the 100 mm mini spool of wire.

8.0 Installation

1010

Optional spool gun purchased separately (not part of this package)

WARNING Ensure that all power to machine is turned o

before connecting the spool gun

12

12

1111

1313

1414

B

B

A

S1

S2

Loading...

Loading...