specied leg length has a throat thickness in excess of the eective

measurement.

Concave Fillet Weld

A llet in which the contour of the weld is below a straight line joining

the toes of the weld. It should be noted that a concave llet weld of

a specied leg length has a throat thickness less than the eective

throat thickness for that size llet. This means that when a concave llet

weld is used, the throat thickness must not be less than theeective

measurement. This entails an increase in leg length beyond the

speciedmeasurement.

The size of a llet weld is aected by the electrode size, welding speed

or run length, welding current and electrode angle. Welding speed and

run length have an important eect on the size and shape of the llet,

and on the tendency to undercut.

Insucient speed causes the molten metal to pile up behind the arc

and eventually to collapse. Conversely, excessive speed will produce

a narrow irregular run having poor penetration, and where larger

electrodes and high currents are used, undercut is

likely to occur.

Fillet Weld Data

Nominal

Fillet Size (mm)

Minimum Throat

Thickness (mm)

Plate Thickness

(mm)

Electrode Size

(mm)

5.0 3.5 5.0–6.3 3.2

6.3 4.5 6.3–12 4.0

8.0 5.5 8.0–12 & over 4.0

10.0 7.0 10 & over 4.0

Selection of welding current is important. If it is too high the weld

surface will be attened, and undercut accompanied by excessive

spatter is likely to occur. Alternatively, a current which is too low will

produce a rounded narrow bead with poor penetration at the root.

The rst run in the corner of a joint requires a suitably high current

to achieve maximum penetration at the root. A short arc length is

recommended for llet welding. The maximum size llet which should

be attempted with one pass of a large electrode is 8.0 mm. Eorts to

obtain larger leg lengths usually result in collapse of the metal at the

vertical plate and serious undercutting. For large leg lengths multiple

run llets are necessary. These are built up as shown below. The angle

of the electrode for various runs in a downhand llet weld is shown

below.

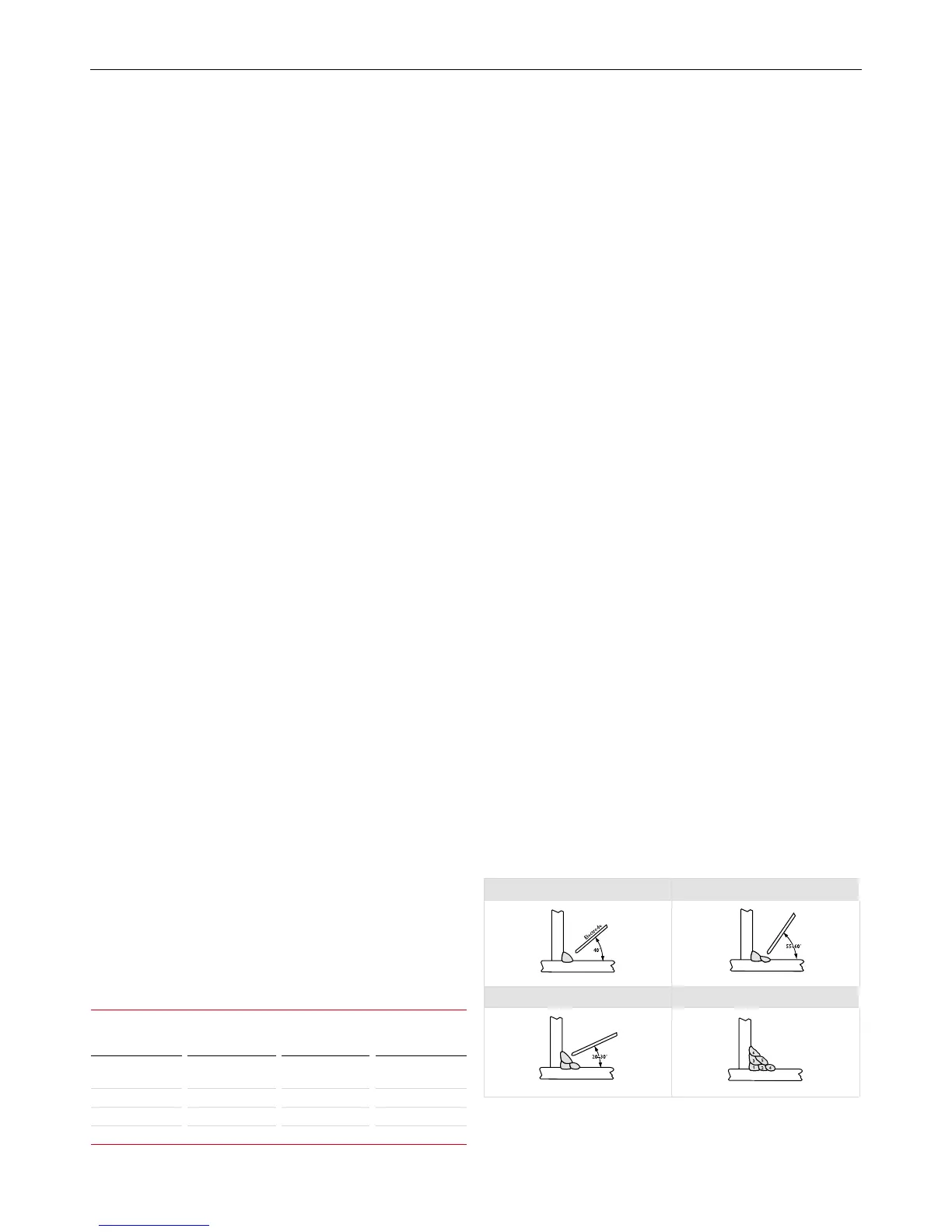

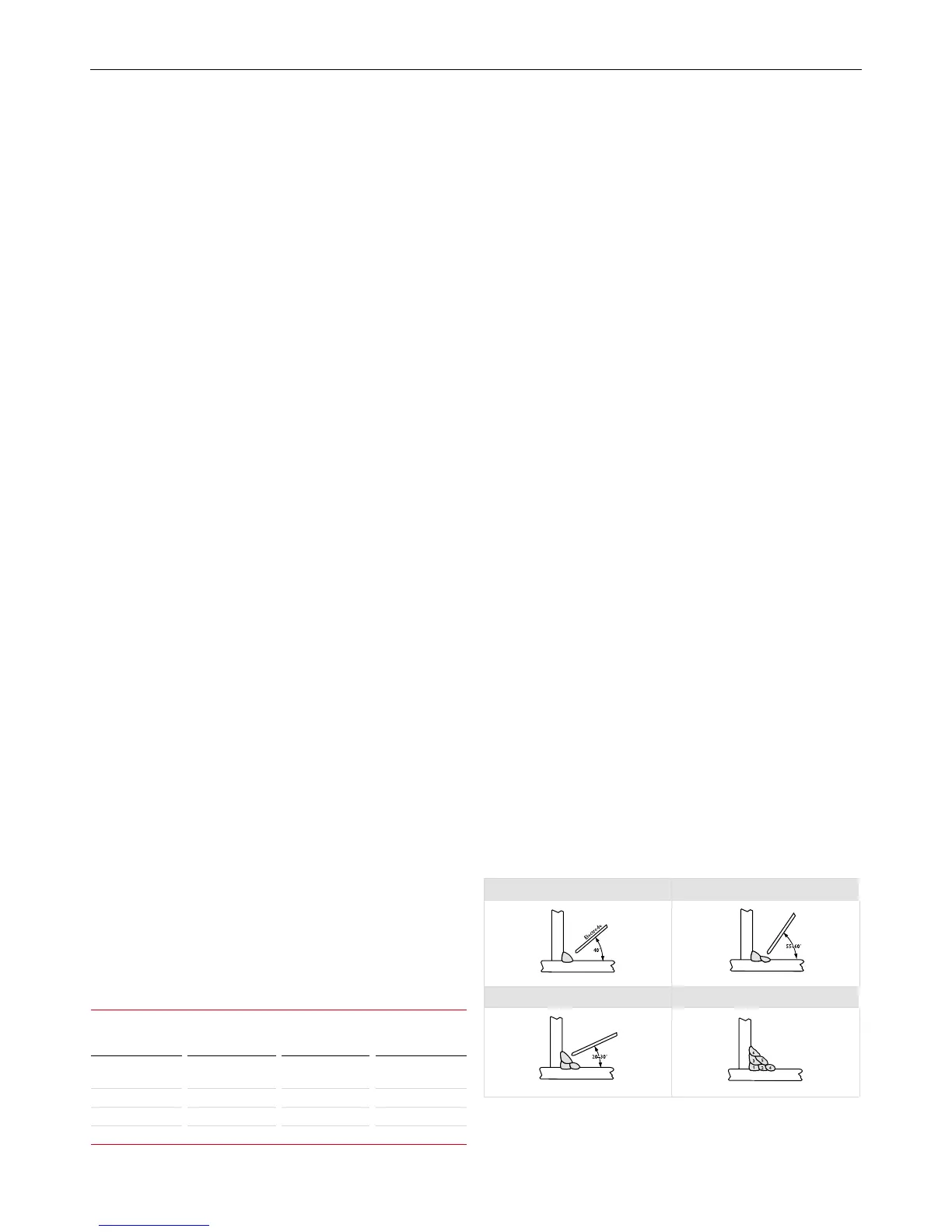

Recommended Electrode Angles for Fillet Welds

1st Run 2nd Run

3rd Run Multi-run Fillet

Multi-run horizontal llets have each run made using the same run

lengths (run length per electrode table). Each run is made in the same

direction, and care should be taken with the shape of each, so that it

31BOC Smootharc 180 Multiprocess operating manual

Loading...

Loading...