42

BOC Smootharc 180 Multiprocess operating manual

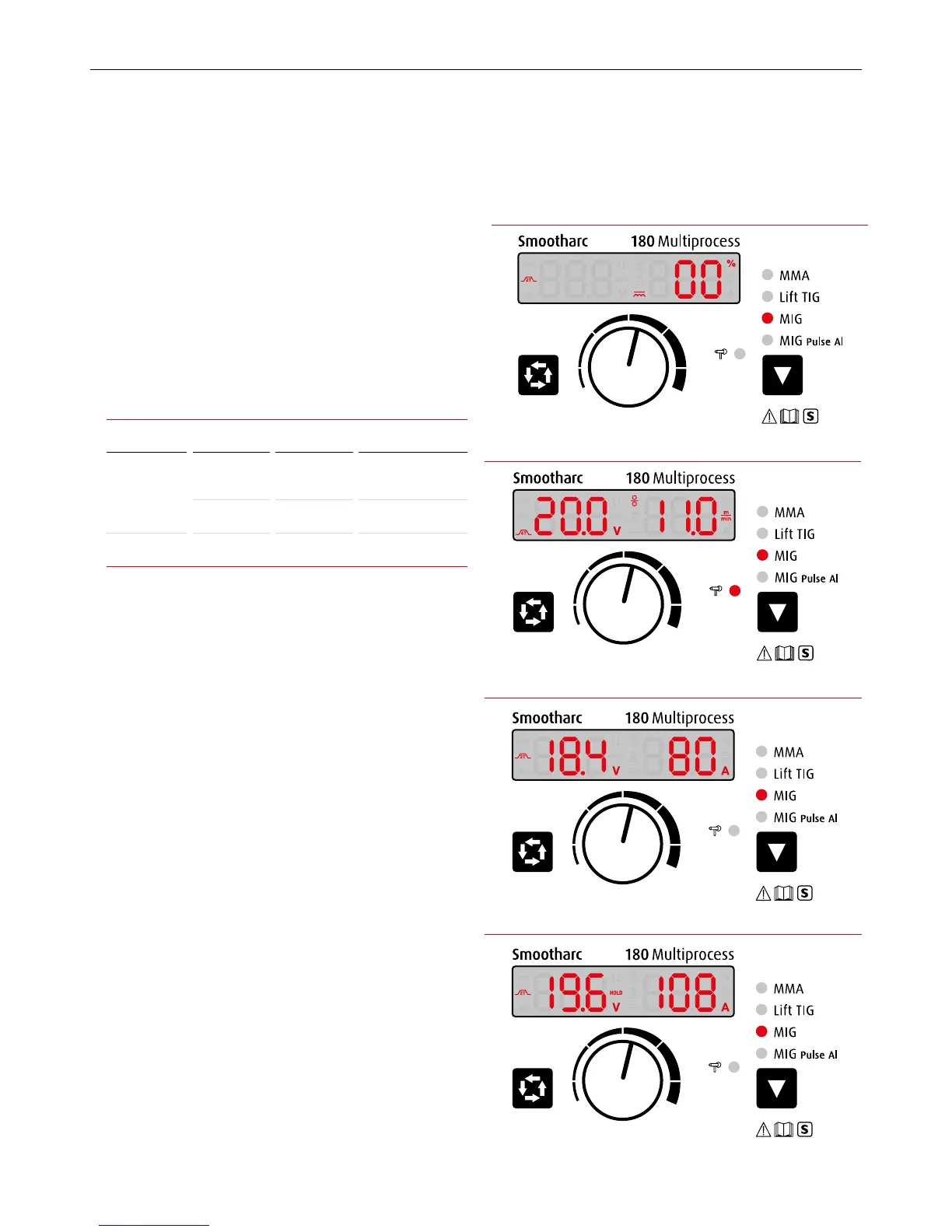

Illustration 8. MIG mode – When stopped welding

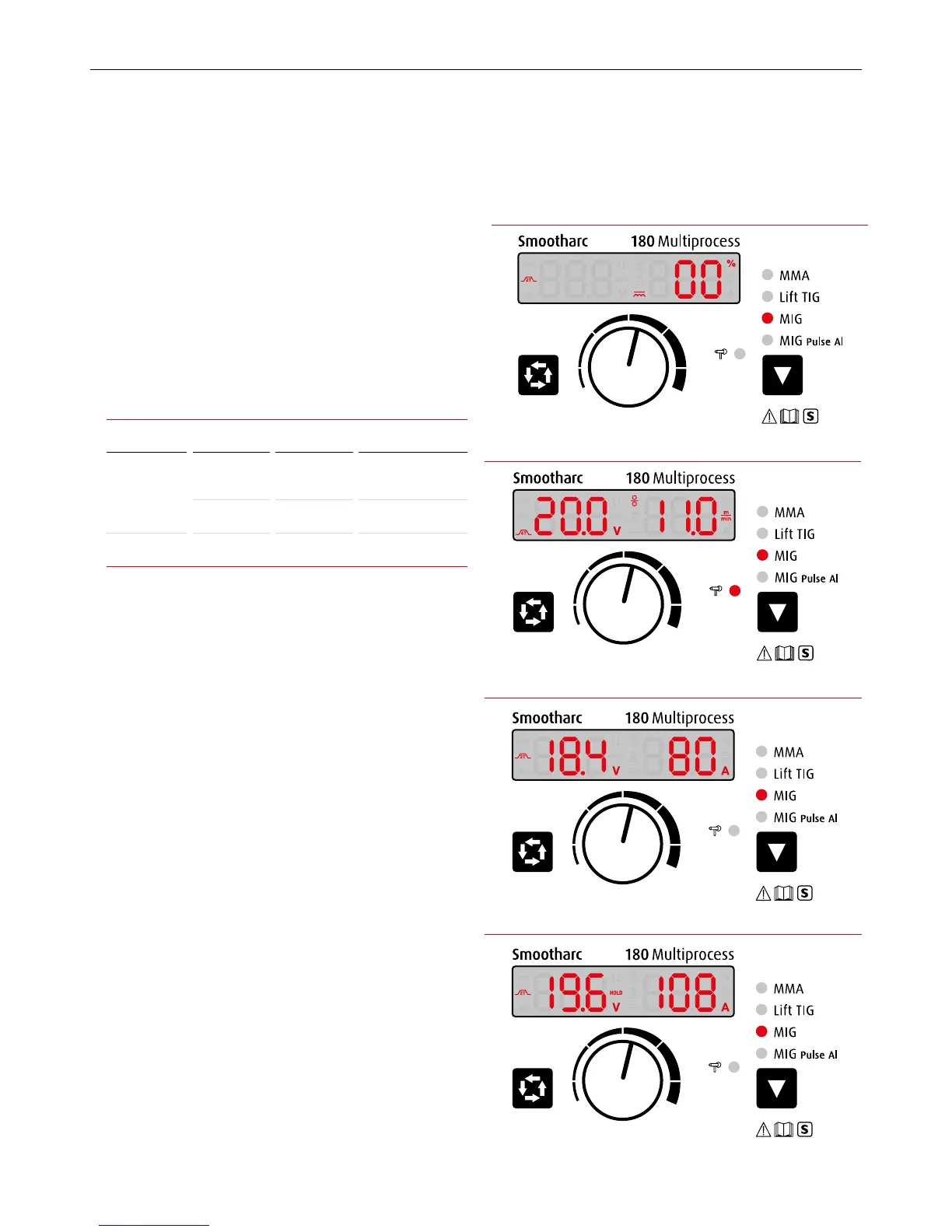

Illustration 6. MIG mode – Using optional spool gun

Illustration 5. MIG mode – Current preset

Press the 2 Data Selection Key twice. The 1 Multifunctional Data

Display is shown as Illustration 5, this allows inductance adjustment

in the range of ±10%

Without any operation after 5 seconds, the 1 Multifunctional Data

Display will revert back to the default setting. The settings will be

retained when the machine is turned o, and displayed when the

machinerestarts.

See the table below for detail of welding process parameters.

Welding process parameters

Mode Materials Wire dia. Wire feeding speed

MIG Carbon steel 0.8 mm 3-11 m/min

Carbon steel

/Aluminum

1.0 mm 3-7 m/min

MIG Pulse Al Aluminum 1.0 mm

(Recommend)

2-8 m/min

When welding aluminum, please t the dedicated wire feeding rolls

and replace the torch liner and contact tips with wear parts suitable

for aluminum.

Operation instruction under MIG mode using spool gun

1 The machine will go in to the spool gun welding mode when

connecting with the spool gun. The 4 spool gun indicator and 7 MIG

indicator lights up (Illustration 6).

Note: While connecting to the spool gun (optional), the wire feeding speed is

adjusted on the spool gun.

While connecting with the spool gun, the 7 Function Switch Key is not

adjustable.

2 The panel will display the data last used when restarting the

machine.

3 The panel displays as Illustration 7 when welding.

4 When releasing the torch switch and welding stops, the panel

displays as Illustration 8. Also, “HOLD” ashes for 3 seconds.

The 1 Multifunctional Data Display redisplays the preset current

after2Seconds.

Illustration 7. MIG mode – When welding

Loading...

Loading...