Copyright 12/14 63 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

BELT/CHAIN TENSION

GENERAL RULES FOR TENSIONING

1. Check tensioning during the first 2-48 hours of run-in operation.

2. Over tensioning shortens belt and bearing life.

3. Keep belts free from foreign materials that may cause the belt to slip.

4. Make V-drive inspection on a periodical basis. Never use belt dressing as this will damage

the belt and cause early failure.

5. Belts should never be forced over the sheave. Allow enough room for belts to slip on.

6. Always make sure sheaves are aligned properly.

TENSIONING PROCEDURE

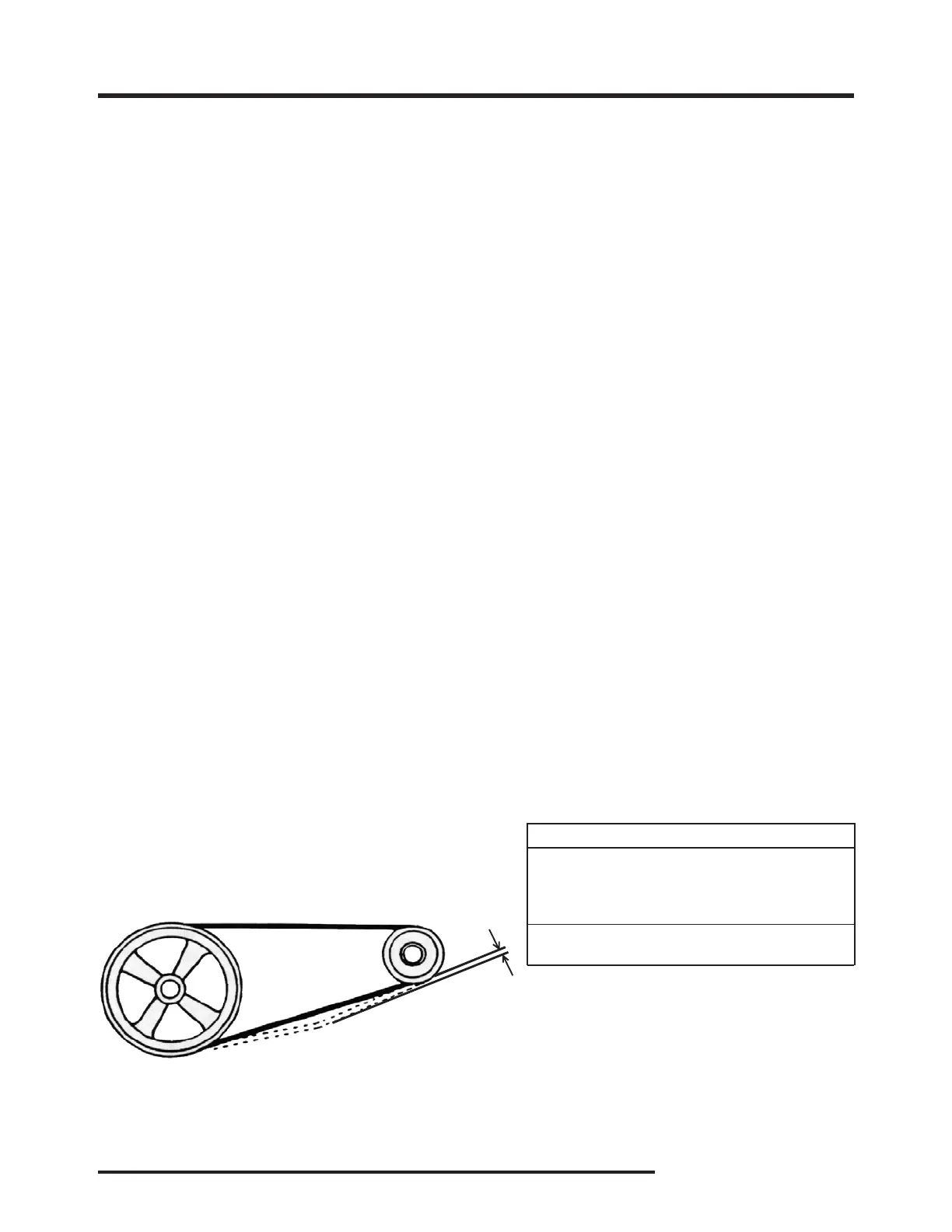

Main Drive Belts (8V or 5V Kevlar Banded Belts)

Locate the center of the belt span between the sheaves. Push or pull on the belt until the belt has deflected 7/8”

(22.2 mm) to 1” (25.4 mm). Record the push or pull force. For a new belt the force should be 19-22 lbs./belt (8.6-

10.0 kg/belt) for the 5V belts, and 35-39 lbs./belt (15.9-17.7 kg/belt) for the 8V belts. After the break in period the

normal force should be 14-20 lbs./belt (6.4-9.1 kg/belt) for the 5V belts, and 25-32 lbs./belt (11.3-14.5 kg/belt) for

the 8V belts.

NOTE: lbs./belt (kg/belt) is per 1 belt. For a 5 groove banded belt lbs./belt (kg/belt) must be

multiplied by 5.

NOTE: It is a good practice to rotate the belts during tensioning. Then recheck deflections.

The belts may need to be tightened again.

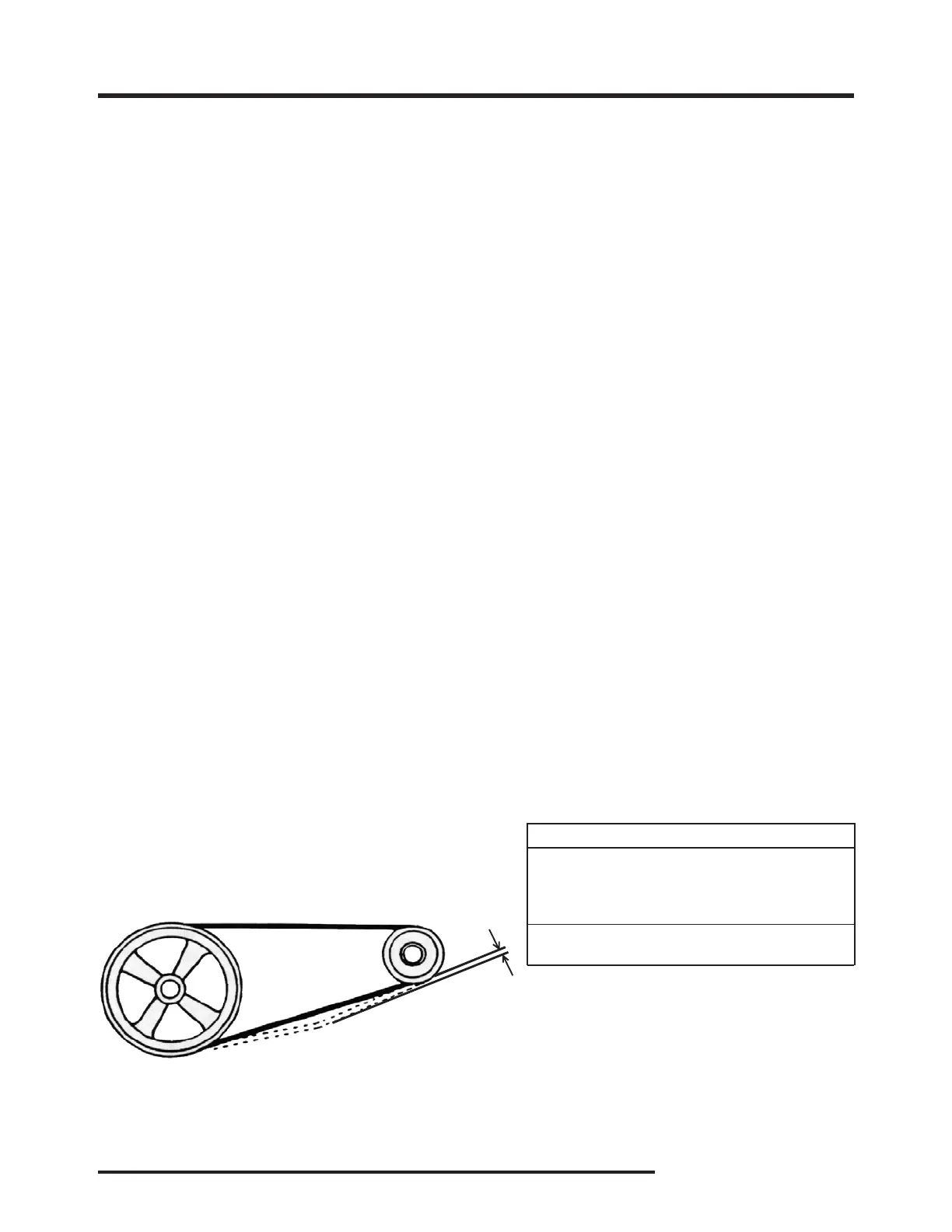

Pump Drive Belts (If Equipped)

Locate the center of the span between sheaves. Push or pull down on the belt until the belt has deflected 1/4”

(6.4mm). Record the push or pull down force. For a new belt the force should be 14-17 lbs (6.4-7.7 kg). After the

break-in period the normal force should be 10-15 lbs (4.5-6.8 kg). Adjust the belt tension if the force falls outside of

this range.

DO NOT IGNORE THIS MAINTENANCE RULE!

New belts stretch very soon and must be adjusted several times in the first few hours of

operation. Adjust after one hour of operation, then every four hours until the belts quit stretching.

Failure to do this will cause the belts to burn and fly off. THIS FAILURE IS NOT COVERED BY

WARRANTY!

BELT/CHAIN SECTION

DEFLECTION

CHAIN TENSION

Chains should be installed fairly tight with only a small amount of slack. New chains will loosen up slightly as the

joints seat themselves. After the first several weeks of operation, adjust the centers to give a small amount of

slack. With adequate lubrication the chains should not need any further adjustment.

Location Deflection Load

Main Drive 7/8”-1” 5V 19-22 lbs.

(22.2-25.4mm) (8.6-10.0 kg)

(Kevlar Banded) 8V 35-39 lbs.

(15.9-17.7 kg)

Pump 1/4” 14-17 lbs.

(6.4mm) (6.4-7.7 kg)

Loading...

Loading...