Copyright 12/14 50 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

CUTTERHEAD SECTION

CUTTERHEAD SECTION

NEVER RUN THE MACHINE WITH THE FOLLOWING FAILURES. THIS WILL CAUSE SERIOUS

DAMAGE TO YOUR MACHINE AND POSSIBLE SERIOUS INJURY TO OPERATORS.

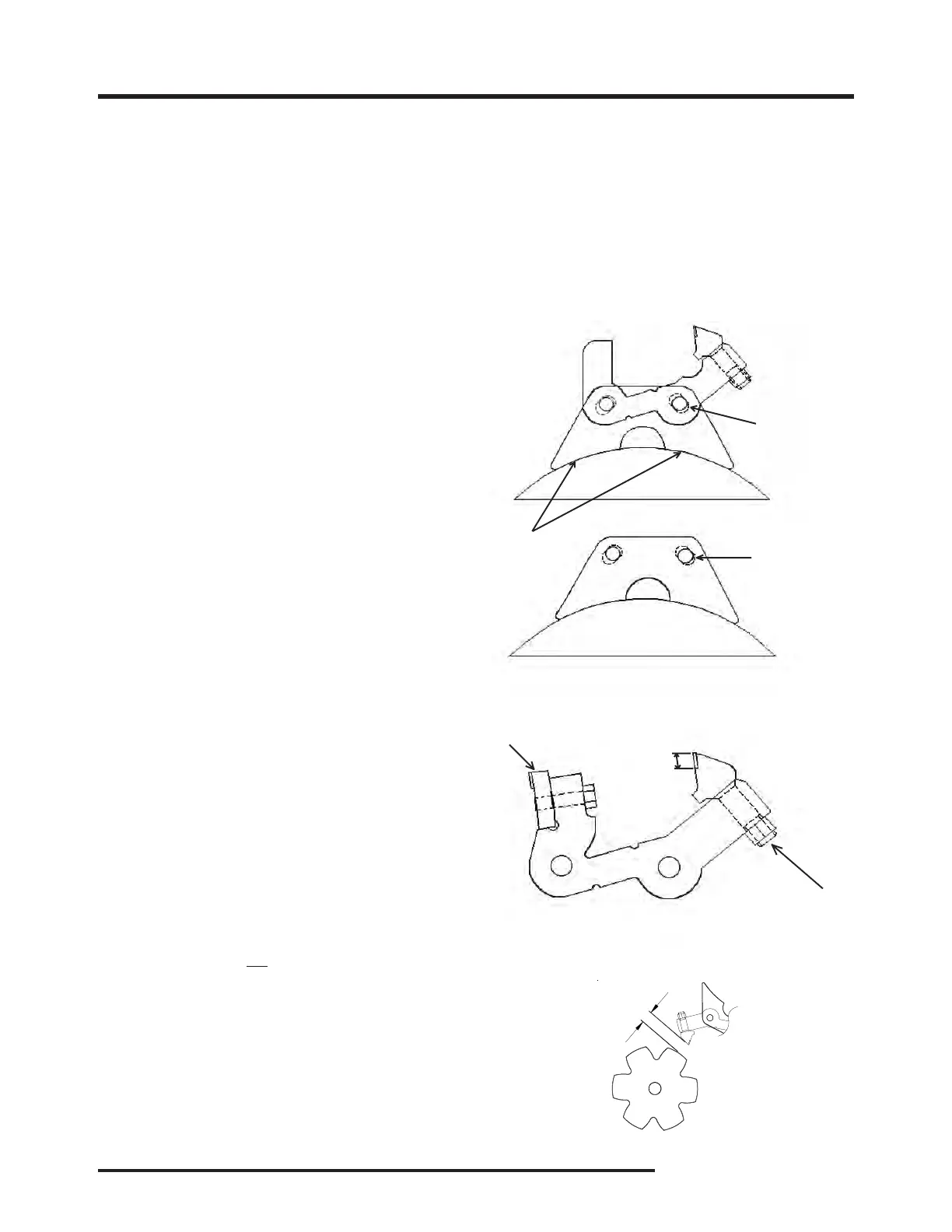

The single most important thing to understand is that

bolts will come loose due to the pounding and the

vibration of the machine. ALWAYS keep the

Cutterbody bolts tight (700 ft.-lbs. or 949 Nm). Failure

to do so will cause premature wear to the Cutterbody.

Loose bolts could also cause the holder arm to crack.

(See Figure 1)

Replace holder arms if the mounting holes measure

more than 1.042” (26.5 mm). (See Figure 2)

ALWAYS use Smoracy, LLC replacement parts. Using

parts not made for the machine could cause premature

damage to the machine.

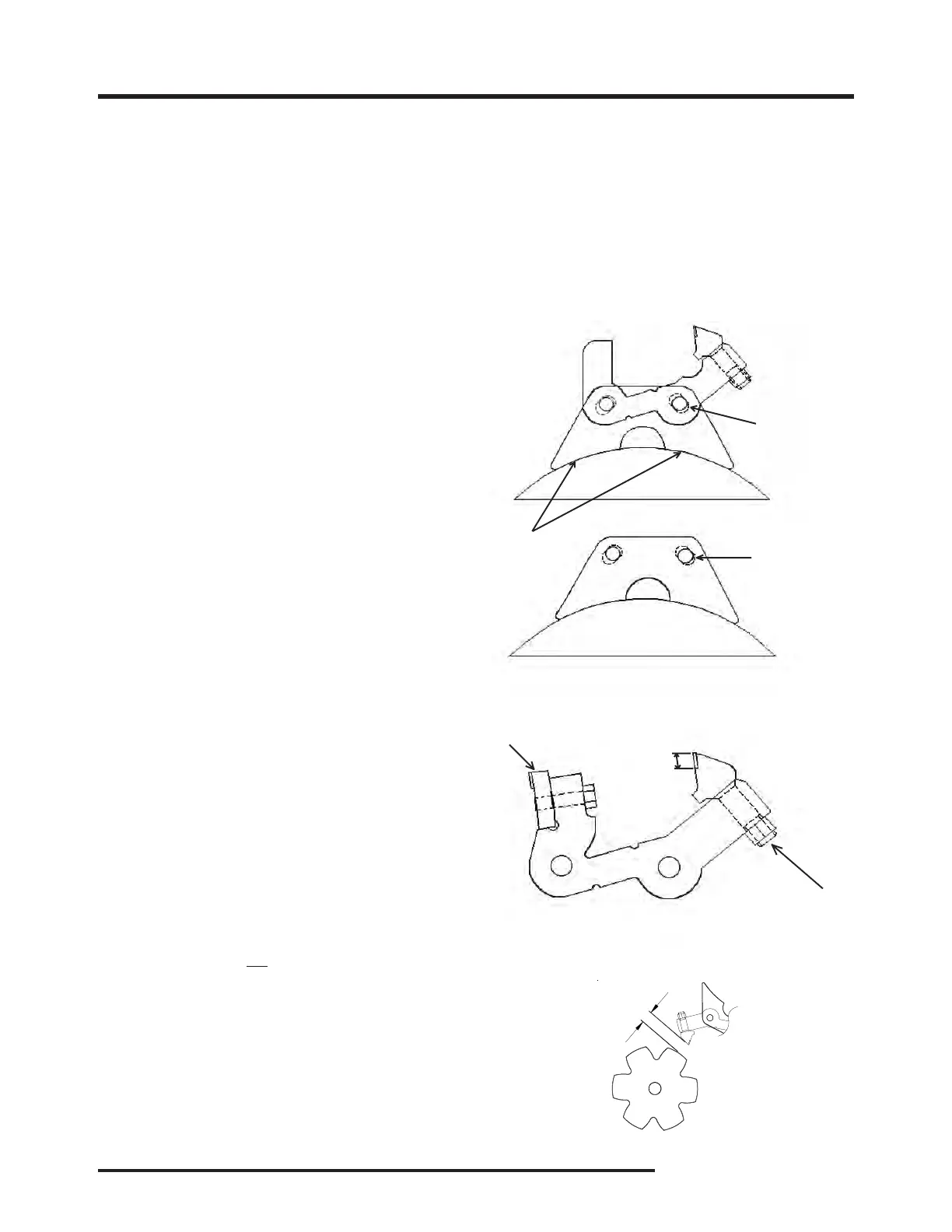

ALWAYS keep Cutterteeth tight. Torque to 500 ft.-lbs.

(678 Nm).

NEVER allow the Cuttertooth to fall below 1/8” (3.2 mm)

of carbide or wear material. Replace immediately. (See

Figure 3)

ALWAYS keep the optional Raker Inserts tight. Torque

to 376 ft.-lbs.(510 Nm).

The Cutterbody holder bolts should be 1/8” (3.2 mm)

from the edge of the arm. When clamping the Cutterbody

be sure the nut does not bottom out.

NOTE: It is a good practice to stop after 20 or 30

minutes of running new teeth and/or Cutterbodies in

order to retighten any loose nuts and bolts to their

specified torque.

Adjust the Infeed Conveyor Chain tension daily.

Incorrect adjustments will cause expensive Cutterhead

and Infeed Conveyor Chain damage. Always keep chain

tension so the chain link runs in the center of the

inspection window. The Infeed Conveyor Chain location

must be 3/4” (19.1 mm) from the tip of a new tooth.

Measure from the end sprockets of the chain head shaft

as shown (Figure 4).

The Cutter head is one of the most important components to keep a preventive maintenance schedule on. The

Cutterhead is the heart of your Recycler, it does most of the work. The Cutterhead MUST be maintained daily.

Watch your Cutterteeth patterns. Experiment with different styles of Cutterteeth, and patterns. Learn what

works best for you and your machine. We cannot stress enough how important it is to maintain your

Cutterhead.

Raker Insert

Torque to 376 FT.-LBS.

(510 Nm)

Figure 1

Figure 2

Figure 3

Mounting Holes

Check For

Cracks

Keep Bolts Torqued To

700 FT.-LBS. (949 Nm).

Oblong Holes Will Occur

Due To Loose Bolts.

Torque to 500 FT.-LBS.

(678 Nm)

Minimum 1/8”

(3.2 mm) Wear

On Carbide

3/4”

(19.1mm)

Figure 4

Loading...

Loading...