Copyright 12/14 51 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 CUTTERHEAD SECTION

CUTTERBODY

The Cutterbody used in the Beast has a leading edge

referred to as the “raker”. The raker is designed to

control the depth of cut that the Cuttertooth will take.

As the Raker wear it allows the Cuttertooth to take larger

and larger cuts. If using a small hole screen taking

large cuts means that the material has to beat around

inside the Cutterhead housing until small enough to exit

through the screen. This robs horsepower that could

be used at the Cuttertooth. Also, taking bigger cuts

puts undue stress on the Cutterhead shaft leading to

possible shaft failure.

When new, the Cutterbody has a hard surface weld

applied to the raker area. It is imperative that this area

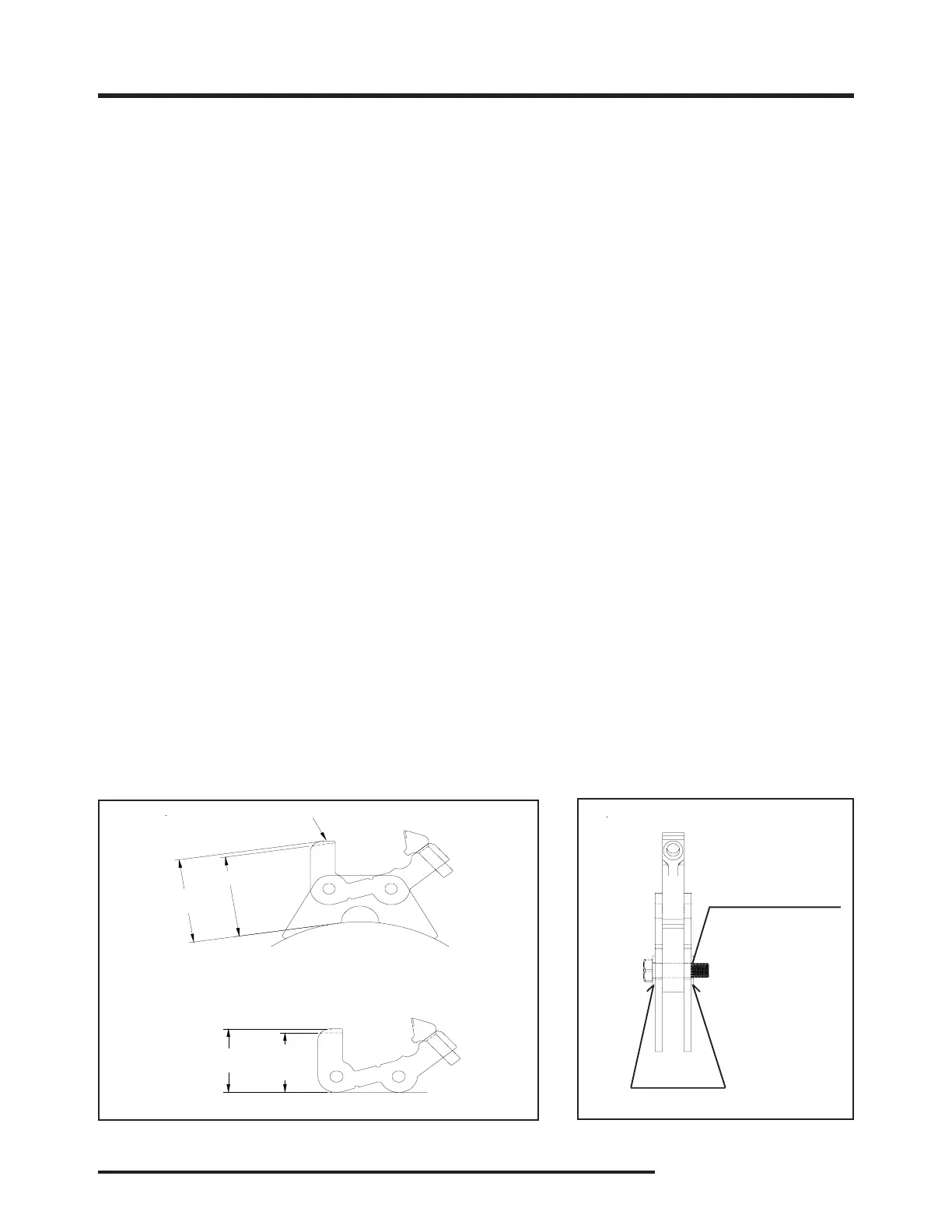

be maintained. The diagrams below show the height of

the raker area when new and the maximum allowable

wear. While in the machine these measurements are

taken from the face of the Cutterhead drum. When worn,

remove the Cutterbody from the Cutterhead and build

up the raker area with a hard surface weld using the

dimensions below as a guide. You could also lay a

worn Cutterbody on a new one to see the amount of

buildup necessary. If using a wire feed welder it is

suggested using a Lincoln Lincore 60-0 or a Stoody

101HC wire. In a stick rod try the Lincoln Wearshield

60 or the Stoody Stoodite 2134. If you have excessive

wear it is recommended that the Cutterbody be replaced

with a new one. Be careful not to buildup above the

height as when it was new as this will affect how the

machine feeds.

Never weld on the Cutterbodies while in the

machine, as there is the potential for fire. It pays to

have several extra Cutterbodies as replacements and

weld up worn ones at your leisure.

CUTTERBODY BOLTS

The Cutterhead of the Beast uses a replaceable

Cutterbody that is designed to fail should something

foreign get into the machine. They take an enormous

amount of abuse with the bolts that hold the Cutterbody

in place being one of the critical components. During

the initial design and testing of this machine a bolt was

developed that is made special for Smoracy, LLC just

for this application. The tolerances and the length of

the shank make it unique to any other bolt on the

market. Maintaining the proper torque of 700 ft.-lbs.

(949 Nm) on this bolt is also extremely critical. Using

the wrong bolts or not keeping them tight allows for

movement between the Cutterbody and the Support

Arms which in turn leads to fatigue and failure. Once

the Cutterbody is allowed to run loose the integrity of

the hole in the Support Arm is lost and must be replaced.

Other wise the bolt will never be able to keep tight again.

If using an air wrench, check it to make sure that it is

capable of reaching the proper torque.

A few customers have had Cutterbodies break loose

from the Cutterhead. In every case it was because they

were not using the proper bolt. A lot of lost time and

money will occur if there is a failure due to using inferior

parts. Any warranty claims will be denied if the

Cutterhead was run with anything other than parts

supplied by Smoracy, LLC.

When ordering new Cutterbodies new bolts must be

ordered as well. Order extra to have on hand for future

use.

NOTE: Take measurement from a flat surface.

Raker Area

Needs Rebuilt

or Replaced

Minimum

Dimension

NOTE: Take measurement from the face of the drum.

Standard Cutterbody

7 1/2” (191 mm)

7 7/8” (200 mm)

NEW

5 5/8” (143 mm)

MAXIMUM

WEAR

6” (152 mm)

NEW

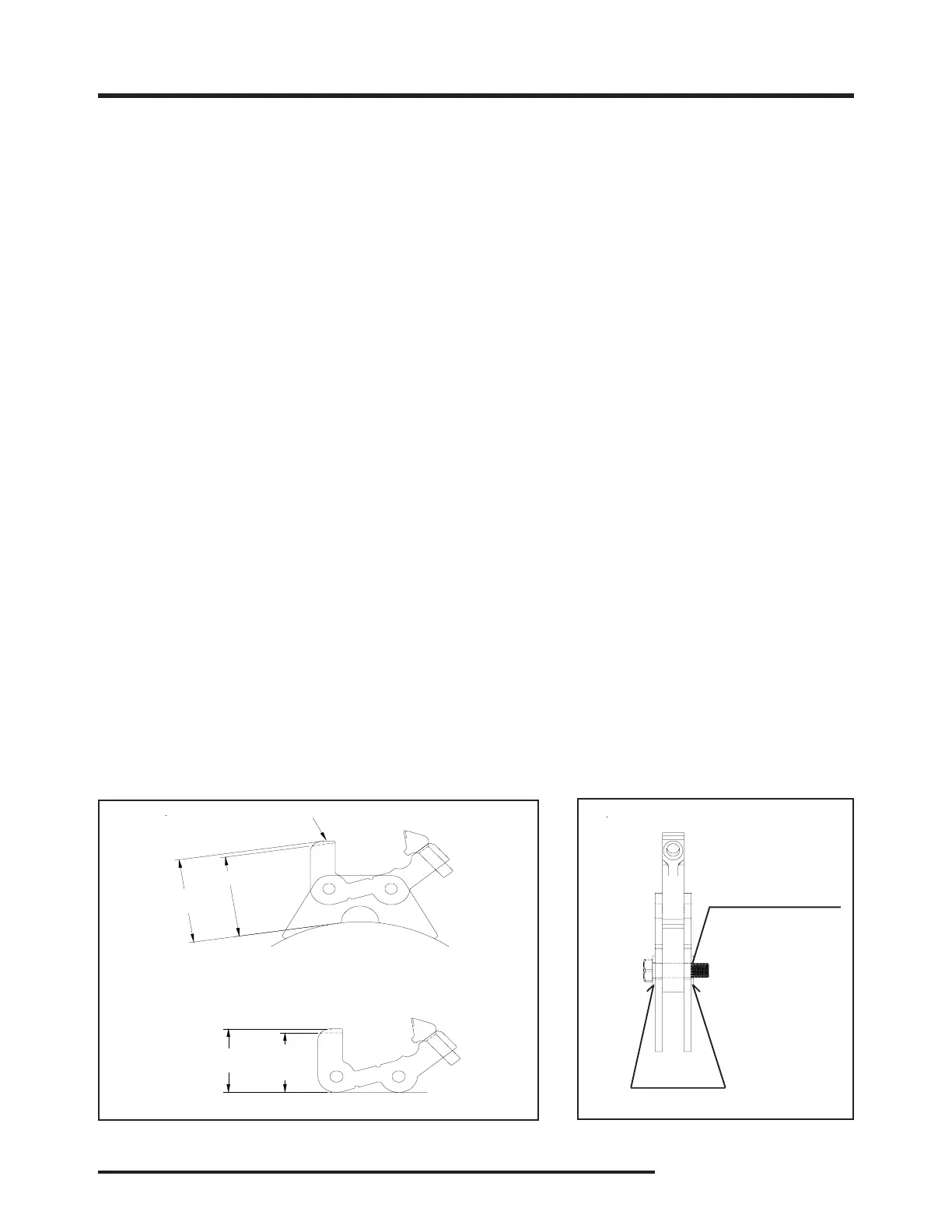

Washers

Approximateley 1/8”

(3.2 mm)

Loading...

Loading...