Copyright 12/14 48 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

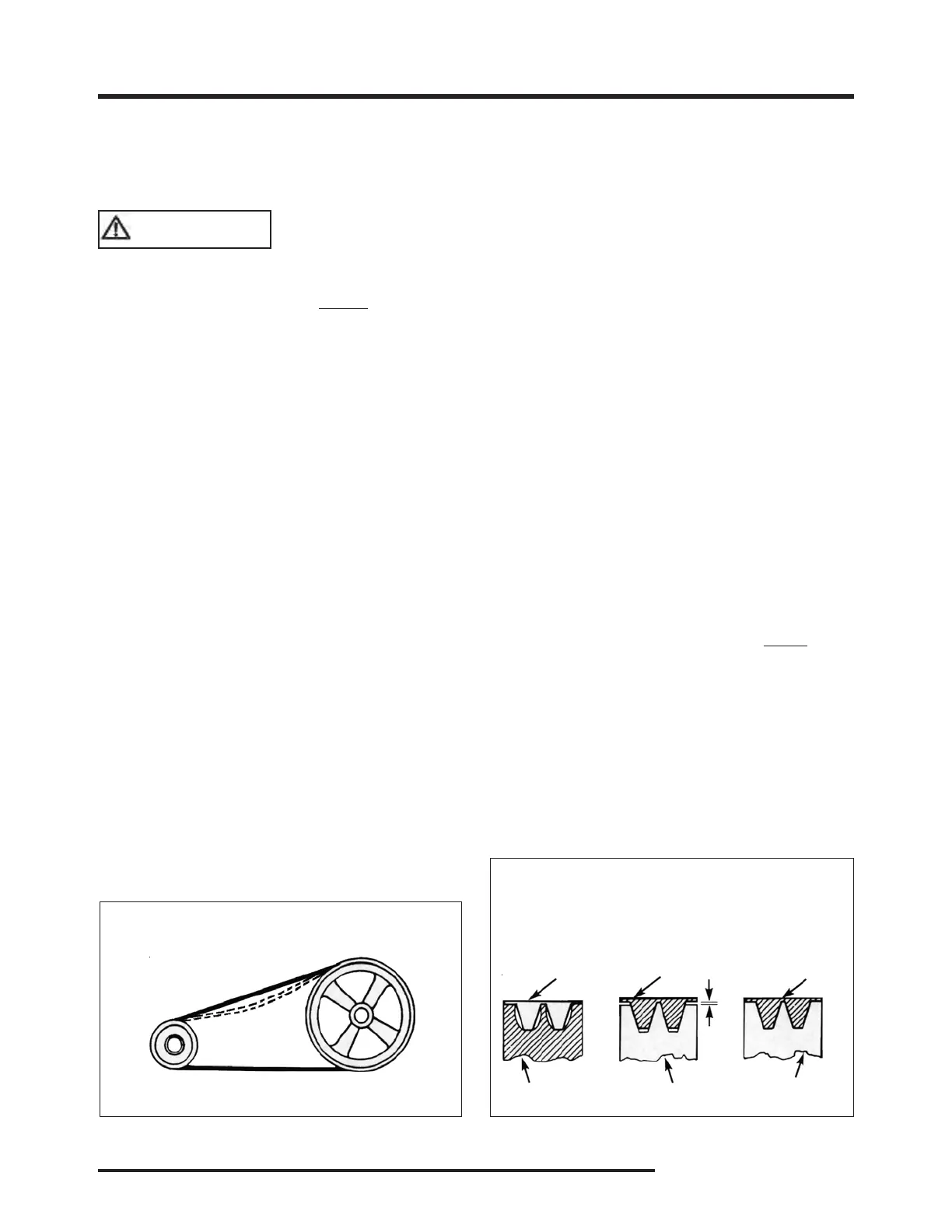

Worn or misaligned belts and sheaves in the power train

causes belt slippage, thus power loss. Keep the power

train working for you, not against you, by checking for

needed adjustment or replacement.

WORN BELT

WORN SHEAVE

GOOD BELT

BELT BELT

SHEAVE SHEAVE

SHEAVE

SPACE

BELT

MAINTENANCE SECTION

RECYCLER BELTS

See”Belt/Chain Section” for the correct specfied

amount of deflection and load per belt.

MAINTENANCE

The Beast Recycler is a very simple machine to maintain. If you will follow a regular scheduled

preventative maintenance program you should have years of trouble free operation.

DANGER

Do not attempt any type of maintenance without first disengaging clutch, turning off engine,

waiting for the Cutterhead to come to a complete stop, turning Battery Disconnect Switch off, and you

must have the ignition key in YOUR possession.

DAILY MAINTENANCE

1) Check the safety decals and engine gauges:

Replace if missing or damaged. Check the engine

manufacturer’s manual to make sure your engine is

running properly.

2) Check all shields and guards:

Check to ensure all shields and guards are securely in

place.

3) Check entire machine for loose bolts, nuts,

parts, or components:

Look for, find and tighten anything that has

loosened up.

4) Check Cutterhead Assembly:

Check for any damage and excessive wear. Check entire

Assembly for loose nuts and bolts

5) Check Cutterbody, Cutterteeth, and Raker

Inserts:

Look for, find and tighten anything that has

loosened up.

Check tooth clearances (3/4” or 19.1 mm min. on infeed

chain) (1/4” or 6.4 mm min. on screen, gate, and anvil)

6) Check and/or adjust the Cutterhead drive

belt tension:

The belts will need to be tightened several times in the

first few days of operation . A loose belt will slip and

then glaze over. Once they slip you must replace them.

See “Belt/Chain Section” for the specified deflection

and load per belt. Check hydraulic pump drive belts

also. (If equipped).

7) Check the hydraulic pump and motor drives:

They should be fully inserted, and fit tight on the pump

motor shaft. If the set screws are loose. Remove them

and apply RC-609 Loc-tite then retighten to the Proper

Torque.

8) Check air cleaner and pre-cleaner, clean or

replace as necessary:

Clean or replace element following engine manual

recommendations. Check and clean Vacutator Valve.

9) Check radiator, debris screen:

Check radiator and debris screen for contamination.

Thoroughly clean radiator and debris screen (if equipped).

10) Check engine oil and coolant levels:

Follow the engine manufacturer manual

recommendations for fluid levels. You MUST follow

specific ENGINE MFG. manual recommendations for

radiator coolant, additives, correct engine speed, ETC.

11) Check hydraulic oil level:

In the hydraulic oil reservoir tank the level should

always remain at 7/8 full.

Loading...

Loading...