■

Lubricants

Specific lubricants as recommended by Snorkel,

should be used in maintaining your unit. If in doubt

regarding the use of lubricants other than those

listed, contact Snorkel.

❑ Pressure gun application

Service all fittings as indicated in the Maintenance

Schedule and lubrication drawing. Wipe away all

excess lubricant from exposed surfaces. Over

lubrication can collect dirt and foreign matter which

acts as an abrasive. Lubrication of accessory

equipment should be in accordance with the

manufacturer’s recommendations.

NOTE

Any time the work platform is elevated to perform

maintenance work, properly position the safety bar

as outlined on the safety prop decal.

DO NOT reach through scissors mechanism

unless the safety prop is properly

positioned.

INJURY or DEATH could occur if the

platform is not supported by the safety prop

and should suddenly drop onto personnel

performing maintenance work under the

raised platform.

❑ Lubrication

Refer to the above lubrication drawing for location

of the following item numbers.

❑ King pins (Item 1)

King pin bearings are self lubricating. Check for

signs of damage and excessive wear as outlined in

the maintenance schedule.

DO NOT lubricate

❑ Tie rods (Item 2)

Tie rod bearings are self lubricating. Check for

damage and excessive wear as outlined in the

maintenance schedule.

DO NOT lubricate

❑ Steer cylinder end (Item 3)

Steer cylinder ends are self lubricating. Check for

damage and excessive wear as outlined in the

maintenance schedule.

DO NOT lubricate

❑ Wheel bearings

Drive wheels (Item 4)

Wheel bearings used on drive wheels are sealed

bearings and do not require lubrication.

SR3370 & SR2770 – 13184B Rev D page 11

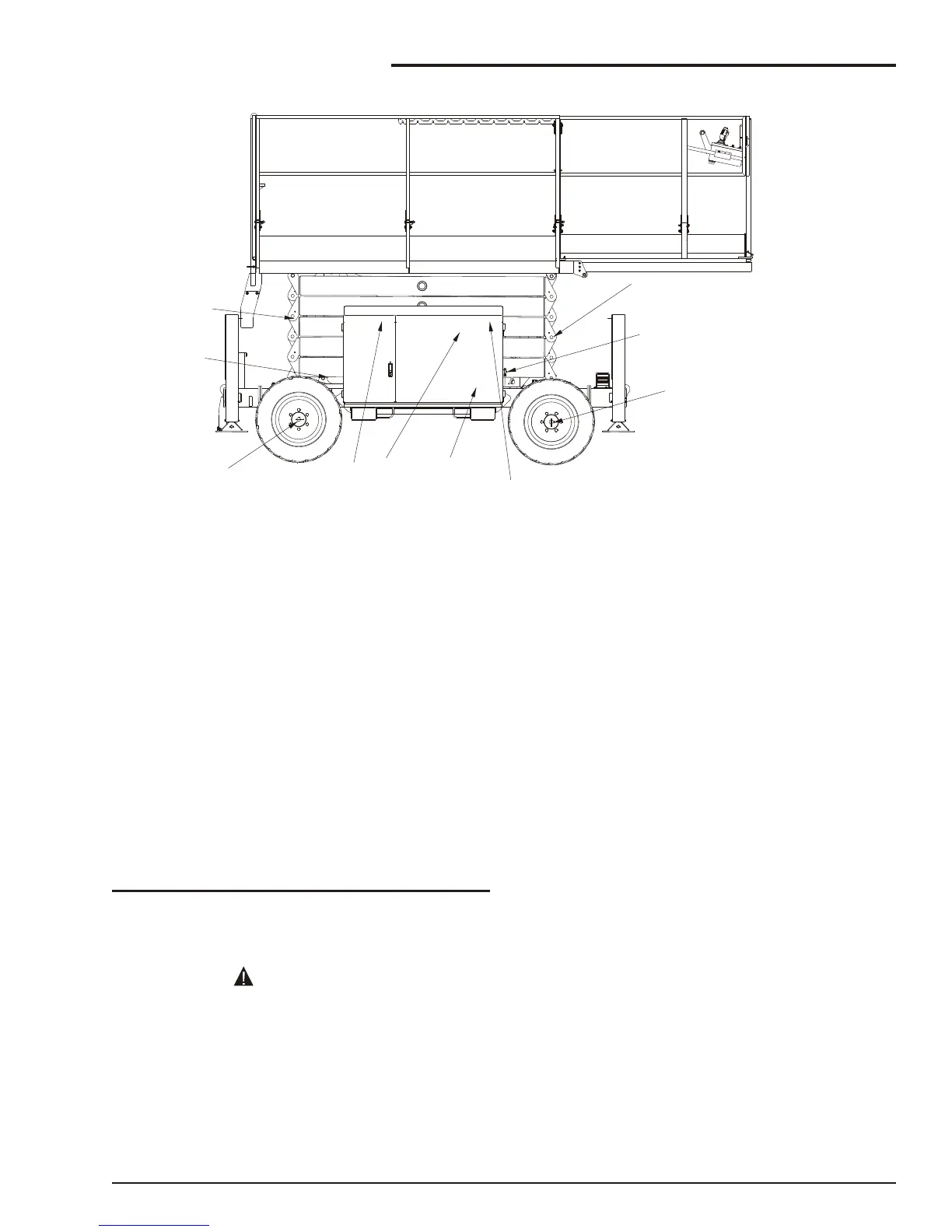

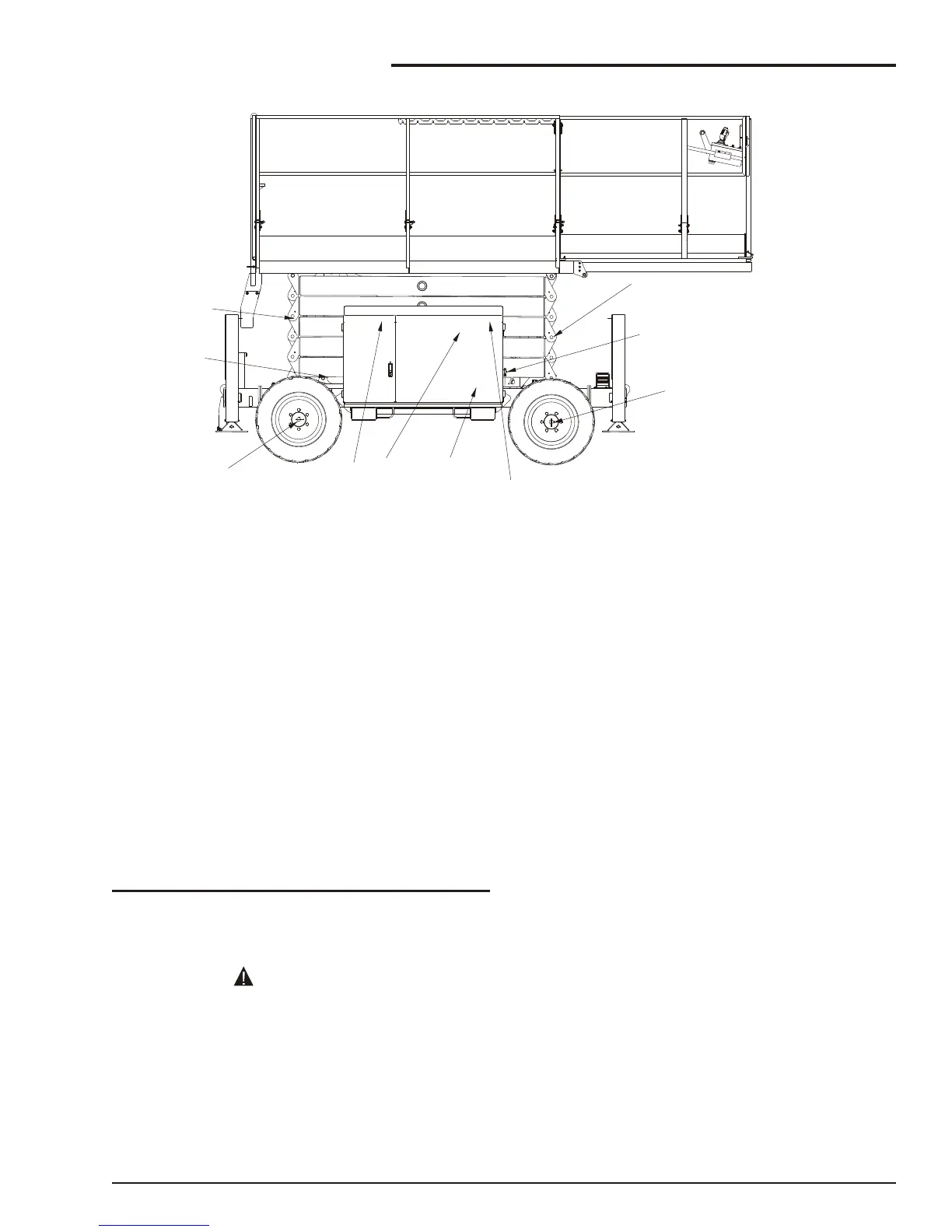

Maintenance Information

10

10

5

11

6

8

1,2,3,4

Includes center

pivot pins

Inside compartment

Inside

cabinet

Inside

engine

cabinet

Inside

compartment

7

4

9

The drawing locates the lubrication points of the SR

Loading...

Loading...