Page 3 - 19TL49J

LOCKING PEG

Each shaft is secured with a locking peg. If a peg is broken or the

bolt and peg is missing then this could be down to a seized shaft

as a result of no lubrication. If a seized shaft is suspected, check

that the x-drilling for the locking peg lines up with the bolt for the

locking peg. Fit a new peg. Carefully operate the boom to deter-

mine if the shaft is trying to turn.

If a grease nipple is tted, apply grease. If the shaft has seized, it

is recommended to drive the shaft 1/2 way out. Clean and apply

new grease. If the shaft is badly worn or scoured, replace both

shaft and the bush. Depending on which shaft is causing the prob-

lem, the structure might need support to prevent jamming when

extracting the shaft.

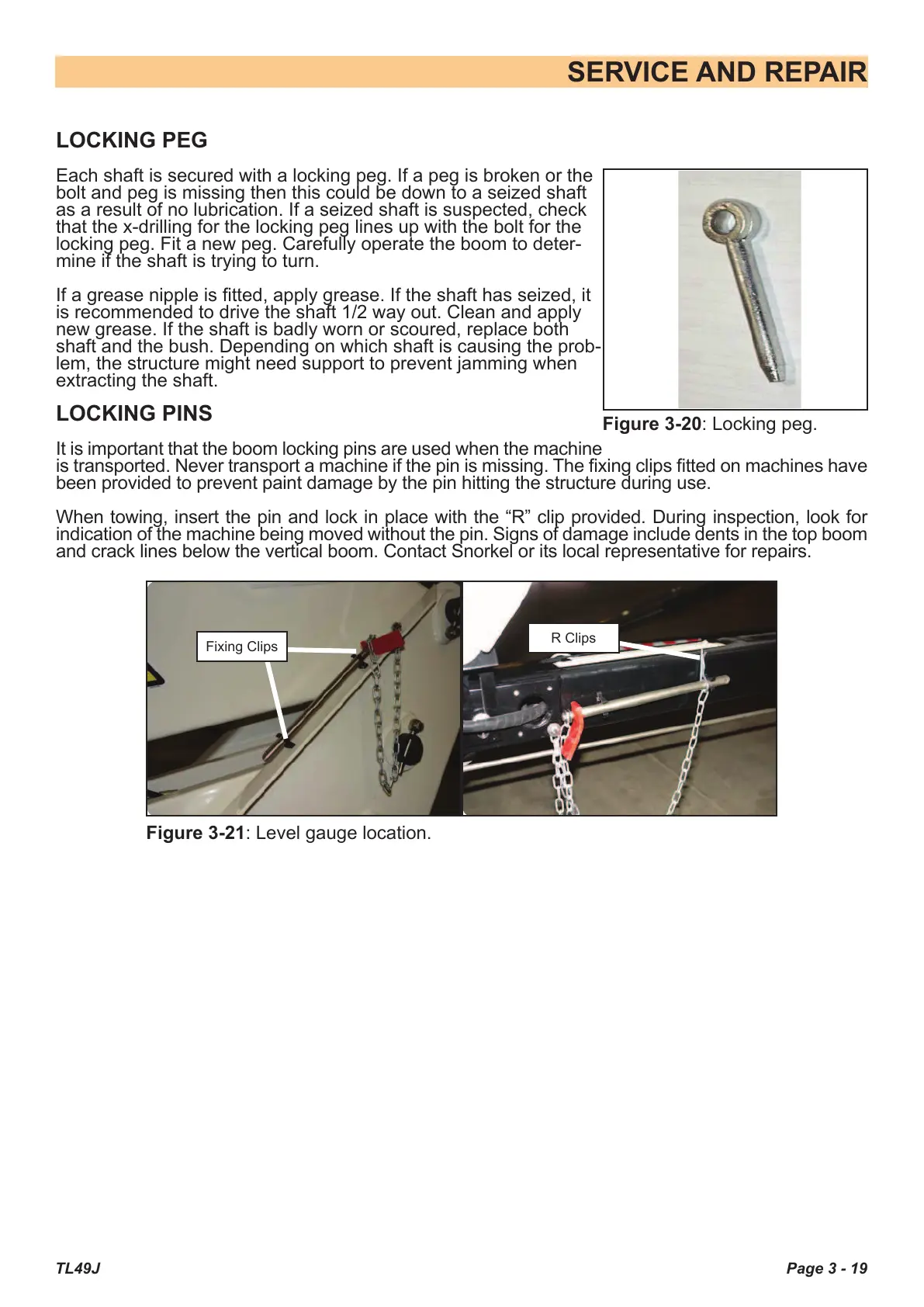

LOCKING PINS

It is important that the boom locking pins are used when the machine

is transported. Never transport a machine if the pin is missing. The xing clips tted on machines have

been provided to prevent paint damage by the pin hitting the structure during use.

When towing, insert the pin and lock in place with the “R” clip provided. During inspection, look for

indication of the machine being moved without the pin. Signs of damage include dents in the top boom

and crack lines below the vertical boom. Contact Snorkel or its local representative for repairs.

SERVICE AND REPAIR

Figure 3-20: Locking peg.

Figure 3-21: Level gauge location.

Fixing Clips

R Clips

Courtesy of Crane.Market

Loading...

Loading...