37

6.3 Commissioning - Quick set-up

This section allows the user to carry out the minimum commissioning necessary to operate

the system.

It accepts the defaults set in the factory, so will only work if the original default settings have

not been altered - see the default settings in Section 10.

Settings can then be tailored to suit the individual requirements of the customer / application

if required.

Warning

It is essential that you comply with National / Local regulations and Guidance notes,

and the boiler manufacturers' recommendations. It is imperative that the settings

you have accepted will allow the boiler to operate in a safe manner.

Calibration water level:

-

Lower the water level to the lowest point required (water must still be visible in the gauge

glass for boiler applications) and ENTER INPUT LEVEL CAL MIN.

-

Raise the water level to the highest point required, and ENTER INPUT LEVEL CAL MAX.

Note: When in the INPUT-LEVEL-CAL menu, the display will show the voltage or

current being output by the level transducer.

ON / OFF control (pumping-in) using an LP20 or PA20.

From the menu select:

OUTPUTS DRIVE CONTROL ON-OFF

Modulating control (pumping in) using an LP20 and PA20 and EL5600 series actuator.

OUTPUTS DRIVE CONTROL PROP

Calibration feedback potentiometer on the EL5600:

Select INPUT POT CAL MIN.

-

The valve will automatically close. When fully closed (voltage will stop decreasing),

press

.

Select INPUT POT CAL MAX.

-

The valve will automatically

open. When fully

open (voltage will stop

increasing), press

OK

.

Test the system to ensure

that it is working correctly.

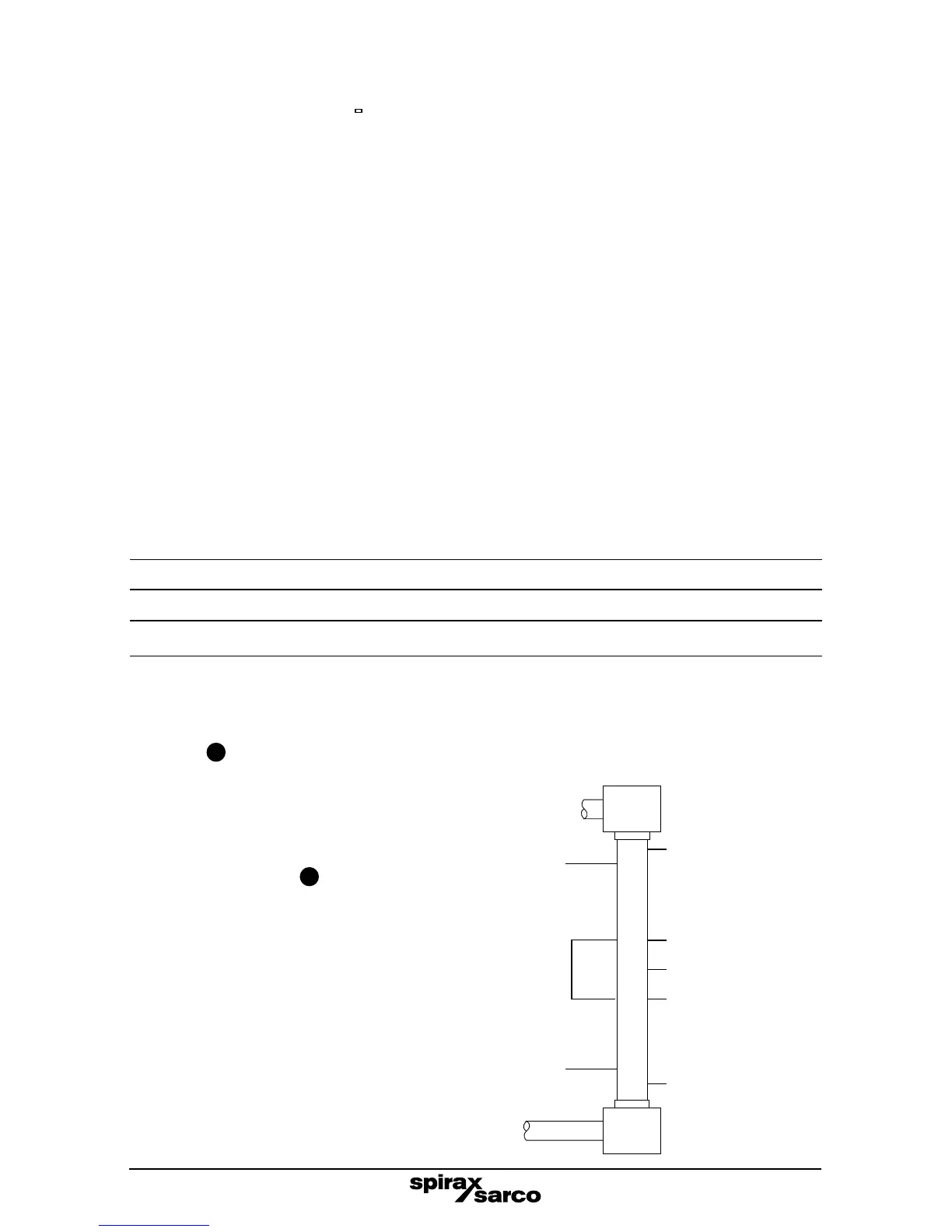

Fig. 24 Typical percentages of level

settings in a gauge glass

100%

Absolute maximum

safe water level

60%

40%

50% Set point

0%

Absolute minimum

water level

(water must always

be visible in glass)

High alarm 85%

Low alarm 20%

Control band 20%

(symmetrical

about set point)

Loading...

Loading...