included) multiply by 2 divide by the no of cylinders. This means that a 60-2 gear for a 6 cylinder

engine is 60*2/6=20.

If the teeth between the sensor and slot is ex 25 then you set it at 5 (teeth – pitch) and change the

coil wires in sequence. Coil 1 connects to driver 2, coil 2 connects to driver 3 and coil 3 connects

to driver 1.

If the teeth between the sensor and slot is ex 47 then you set it at 7 (teeth – 2*pitch) and change

the coil wires in sequence. Coil 1 connects to driver 3, coil 2 connects to driver 1 and coil 3

connects to driver 2. For more info in this please see the drawings supplied on CD.

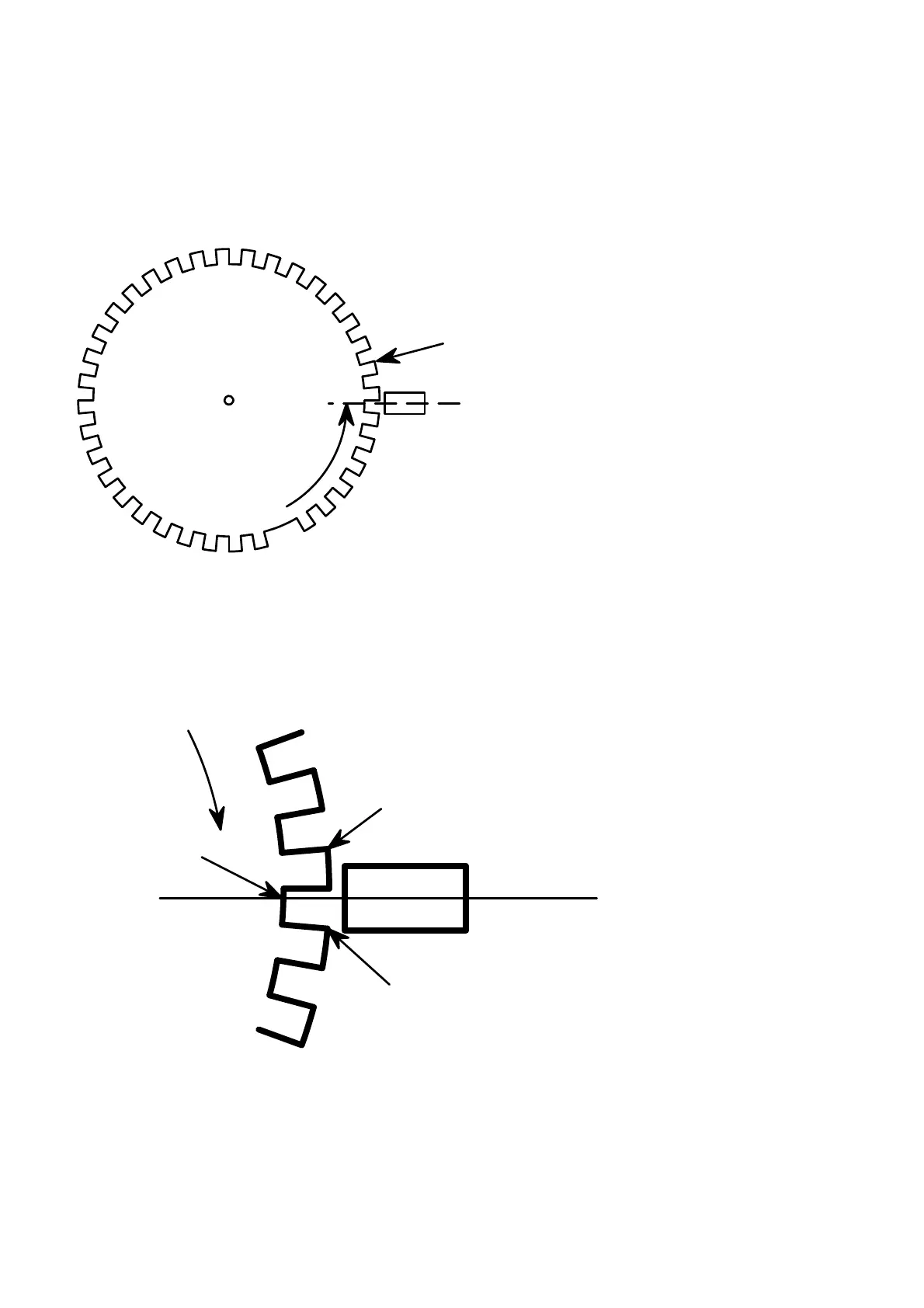

Count anti clockwise from the

slot to the pickup. If the centre of

the pick up sensor is past the last

edge of a tooth, count the next tooth

as well. Put this number in the Gear

teeth block on the Setup page.

last edge of a tooth

centre of the pick up sensor

Example

7 teeth

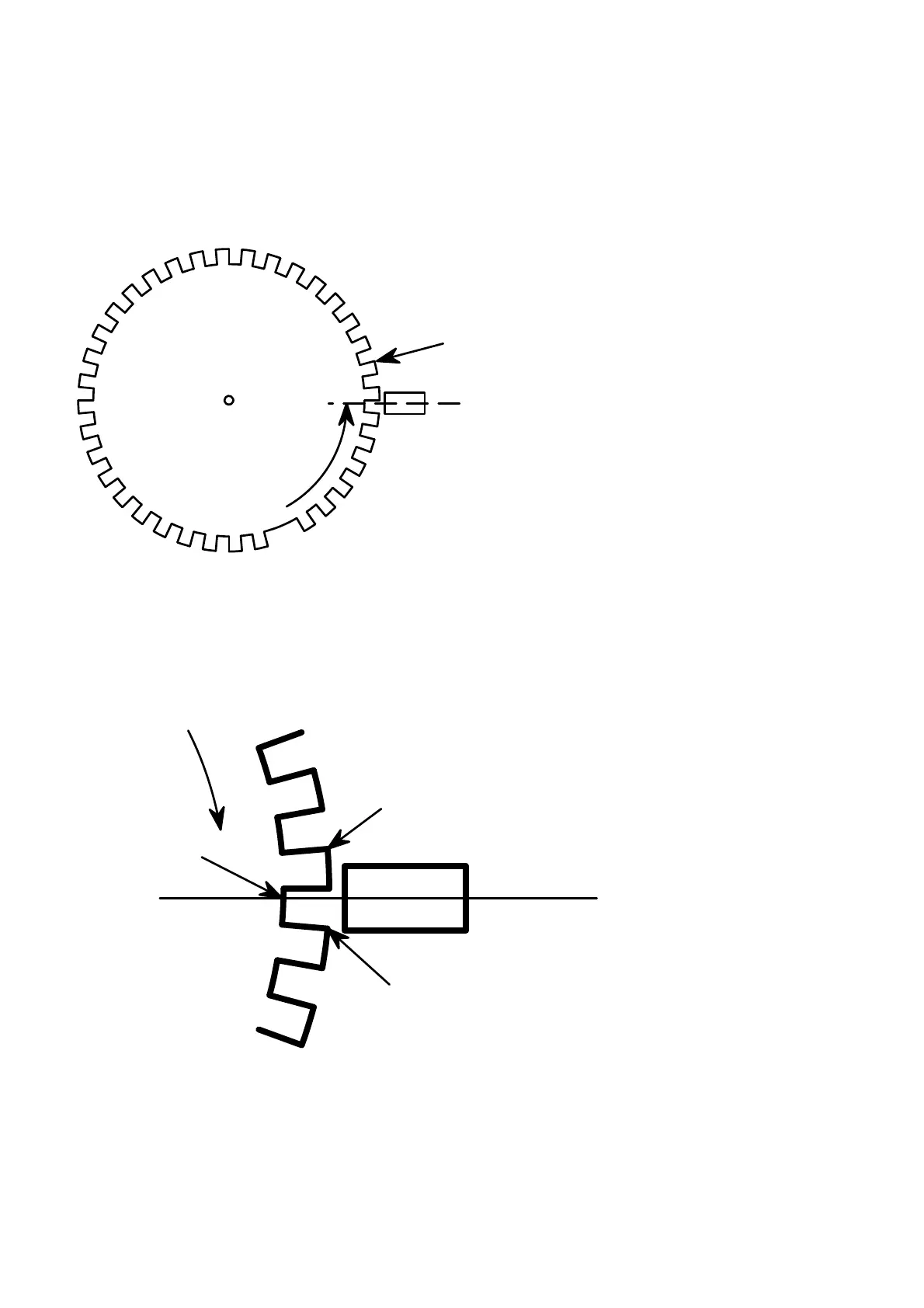

The trigger point of the sensor is the centre of the sensor to the last edge of the tooth or trigger

plate (Trigger Edge 0°). On a 36-1 gear the pitch is 10 degrees. To ajust the Timing BTDC block

you can guess a setting for the centre of the pickup between the trigger edges of the adjacent

teeth. See the sketch below. When the engine is running, adjust it till the software correlates with

the timing light.

Centre of the pick up sensor

Trigger Edge 0°

Trigger Edge 10° or 0° next tooth

Trigger Edge 6°

Crank Rotation

Loading...

Loading...