To start the engine the first time, use the main jet slider. Start with a low value and increase it until

the engine start. If it starts adjust the main jet so that it can idle. Always go for the leanest position

(bottom) on the slider not to over fuel the engine. Check the timing with a timing light to ensure

that your spark setup is correct. Now you can concentrate on the fuel again. Let the engine heat to

normal temperatures. First cancel all the compensation fields to zero and use the main jet slider.

Use the lambda sensor as an indicator to see if you are more or less correct with the fuel. Now

follow the guidelines below.

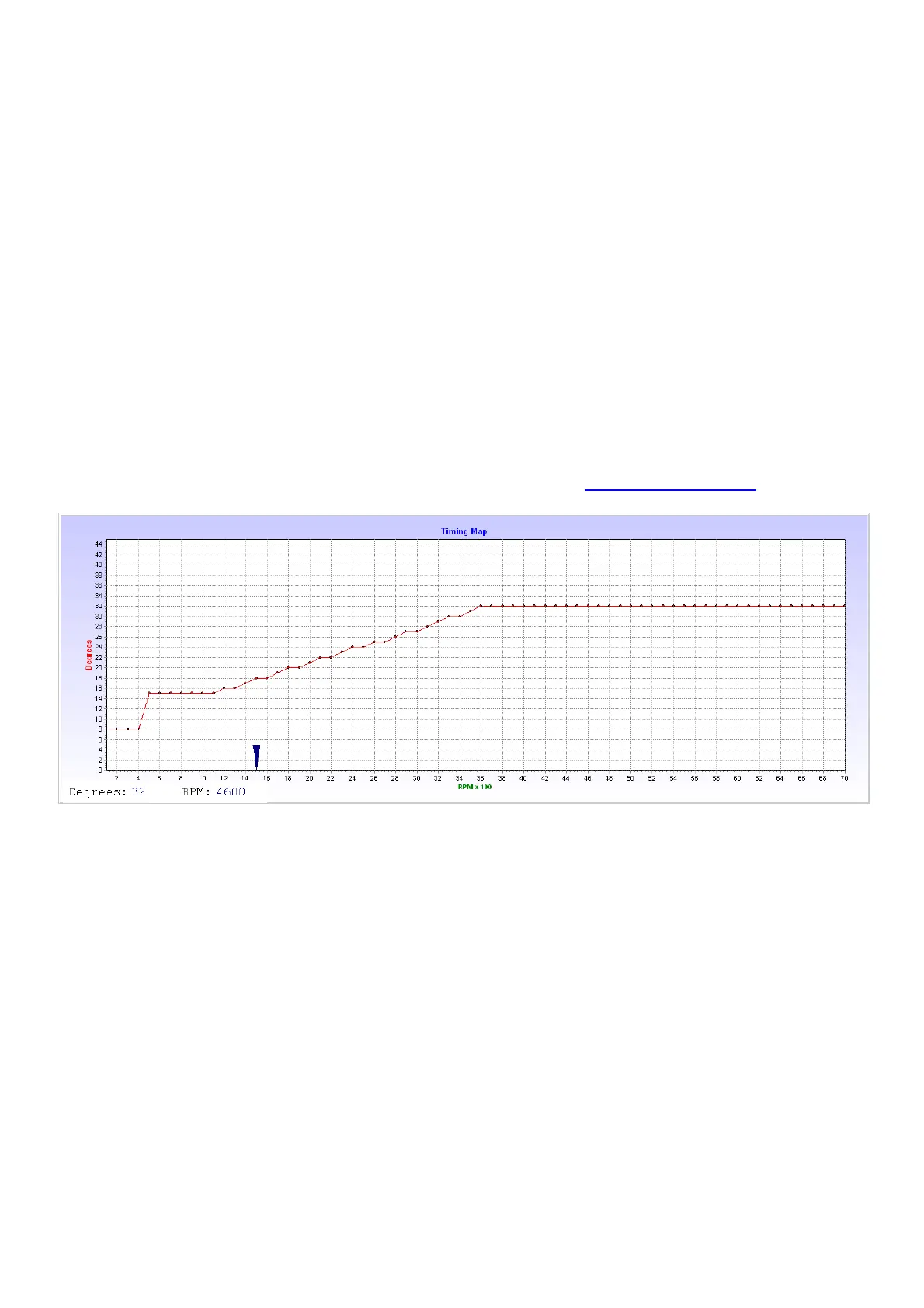

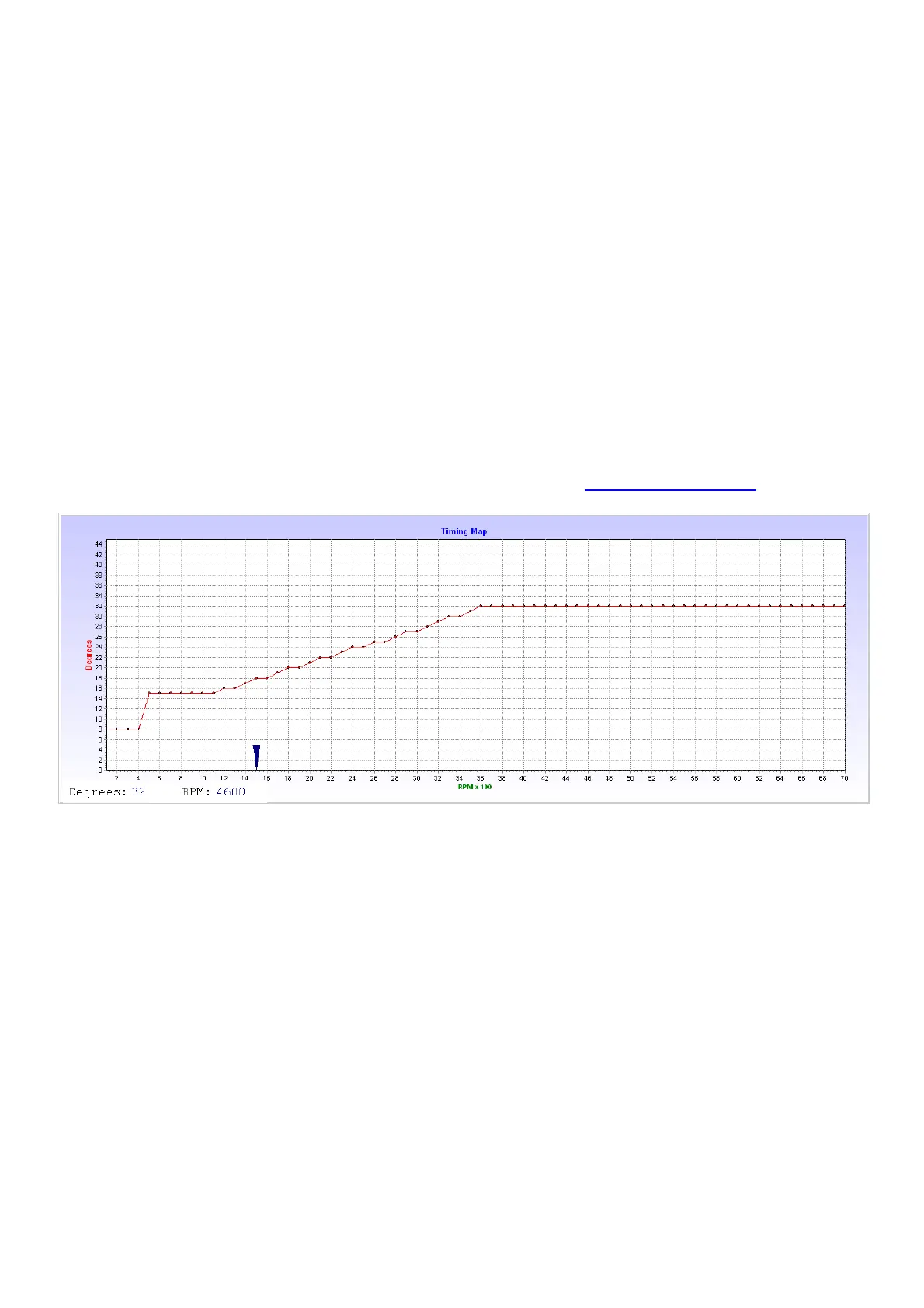

9.3 Ignition Timing Tuning

Most of the ECU’s will come with a fixed setup for a specific engine. Especially where crank

triggers are used. Then you don’t have to do anything except maybe fine tuning on the timing

maps. If you do not have a setup for your engine, then work through this part. First make the

vacuum timing graph zero. Only adjust the dynamic timing on the Timing Map. Make cranking

timing about 8° BTDC and idling timing at about 15° BTDC. As you increase RPM’s increase the

timing up to about 3500RPM. Normally here is the maximum timing which should be around 32°

BTDC. Keep it flat for the rest of the RPM range. This is a basic curve if you do not have any

specs for the engine. See graph below. When the engine is started and idling, ensure that the

software timing is the same as the timing light. If not, adjust the Timing Configuration on the Setup

Page.

On the vacuum timing, keep the graph from the left zero till after the right side of the vacuum bar

at idling RPM. Now increase the timing to around 8° BTDC. Reduce this to the right till 0° BTDC at

WOT vacuum. If you have a turbo, let the graph cross the zero timing at around atmospheric

pressure which is 1Bar. Then keep on reducing the timing to -8° BTDC at full boost pressure.

Turbo engines normally peak at 22-24° BTDC during WOT. If you cannot hear pinging, rather start

off with a slow time and increase small amounts at a time. On a Dyno the optimum timing is

normally were no power is gained by increasing the value. If you have access to a knock sensor

instrument, it should be easy to tune the timing correct. As you get to the optimum fuel mixture you

may start to hear pinging again. Immediately lower the timing curve in that region. Timing should

be 2 to 4 degrees below detonation.

9.4 Air / Fuel Ratio Tuning

Again if you ECU is pre loaded for a specific application, you can give the paragraph a glance-

over. If not, work through it. This is not easy in the beginning as you work in two dimensions with

vacuum versus RPM. Firstly you need to see if your lambda sensor is working correctly. Get the

engine at normal operating temperatures. Ensure that all the compensation graphs are zero.

Adjust the idle jet leaner till you can hear the engine loosing RPM’s or you see the vacuum bar

moving to the right of the vacuum fuel map. The lambda should now read on the lean side. If the

idle jet does not seem to make a difference it means the main jet setting is too large. Decrease it

slightly. Look at the millisecond injector bar. The value must decrease when the slider is

Loading...

Loading...