CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor

ormoderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which,

ifnot avoided, may result in property damage.

Improper operation or maintenance of this product could result in serious injury and property damage.

Read and understand all warnings and operating instructions before using this equipment. When using

power tools, basic safety precautions must always be followed to reduce the risk of personal injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING:

• DO NOT use outside the design intent of Placing STANLEY Engineered Fastening Blind Rivets.

• Use only parts, fasteners, and accessories recommended by the manufacturer.

• DO NOT modify the tool in any way. Any modication to the tool is undertaken by the customer and will

be the customer’s entire responsibility and void any applicable warranties.

• Prior to use, check for misalignment or binding of moving parts, breakage of parts, and any other

condition that aects the tool’s operation. If damaged, have the tool serviced before using. Remove any

adjusting key or wrench before use.

• The tool must be maintained in a safe working condition at all times and examined at regular intervals

for damage and function by trained personnel. Any dismantling procedure will be undertaken only by

trained personnel. Do not dismantle this tool without prior reference to the maintenance instructions.

• The operating supply air must not exceed 7 bar (100 PSI).

• Operators and others in work area must wear approved safety glasses with side shields. Always wear

safety glasses and ear protection during operation.

• Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

• DO NOT operate a tool that is directed towards any person(s).

• DO NOT operate tool with the nose casing removed.

• Adopt a rm footing or a stable position before operating the tool.

• Prior to use, inspect airlines for damage, all connections must be secure. Do not drop heavy objects on

Hoses. A sharp impact may cause internal damage and lead to premature hose failure.

• DO NOT lift the placing tool by the hose. Always use the placing tool handle.

• Vent holes must not become blocked or covered.

• Disconnect the air hose from the tool before performing any maintenance, attempting to adjust, t or

remove a nose assembly.

• Keep tool handles dry, clean, and free from oil and grease.

• When carrying the tool from place to place keep hands away from the trigger to avoid inadvertent

activation.

• Never leave operating tool unattended. Disconnect air hose when tool is not in use.

• Adequate clearance is required for the tool operator’s hands before proceeding.

• DO NOT abuse the tool by dropping or using it as a hammer.

• Keep dirt and foreign matter out of the hydraulic system of the tool as this will cause the tool to

malfunction.

• Care should be taken to ensure that spent mandrels do not create a hazard.

• The mandrel collector must be emptied when approximately half full.

• DO NOT use the tool without mandrel collector installed.

• DO NOT let air exhaust opening on the mandrel collector face in the direction of the operator or other

persons.

• Contact with hydraulic uid should be avoided. To minimise the possibility of rashes, care should be taken

to wash thoroughly if contact occurs.

• Material Safety Data Sheets data for all hydraulic oils and lubricants is available on request from your tool

supplier.

STANLEY Engineered Fastening policy is one of continuous product development and improvement

and we reserve the right to change the specication of any product without prior notice.

2. SPECIFICATIONS

The ProSet® XT1 & XT2 are hydro-pneumatic tools designed to place Stanley Engineered Fastening blind rivets

at high speed

The tools feature a vacuum system for rivet retention and trouble free collection of the spent mandrels

regardless of tool orientation.

When coupled to the relevant nose equipment the ProSet®XT1 & XT2 can be used to place blind rivets in the

range of Ø2.4mm to Ø4.8mm. Refer to the table on page 7 for a list of all rivets that can be placed.

The safety warnings on pages 4 & 5 must be followed at all times.

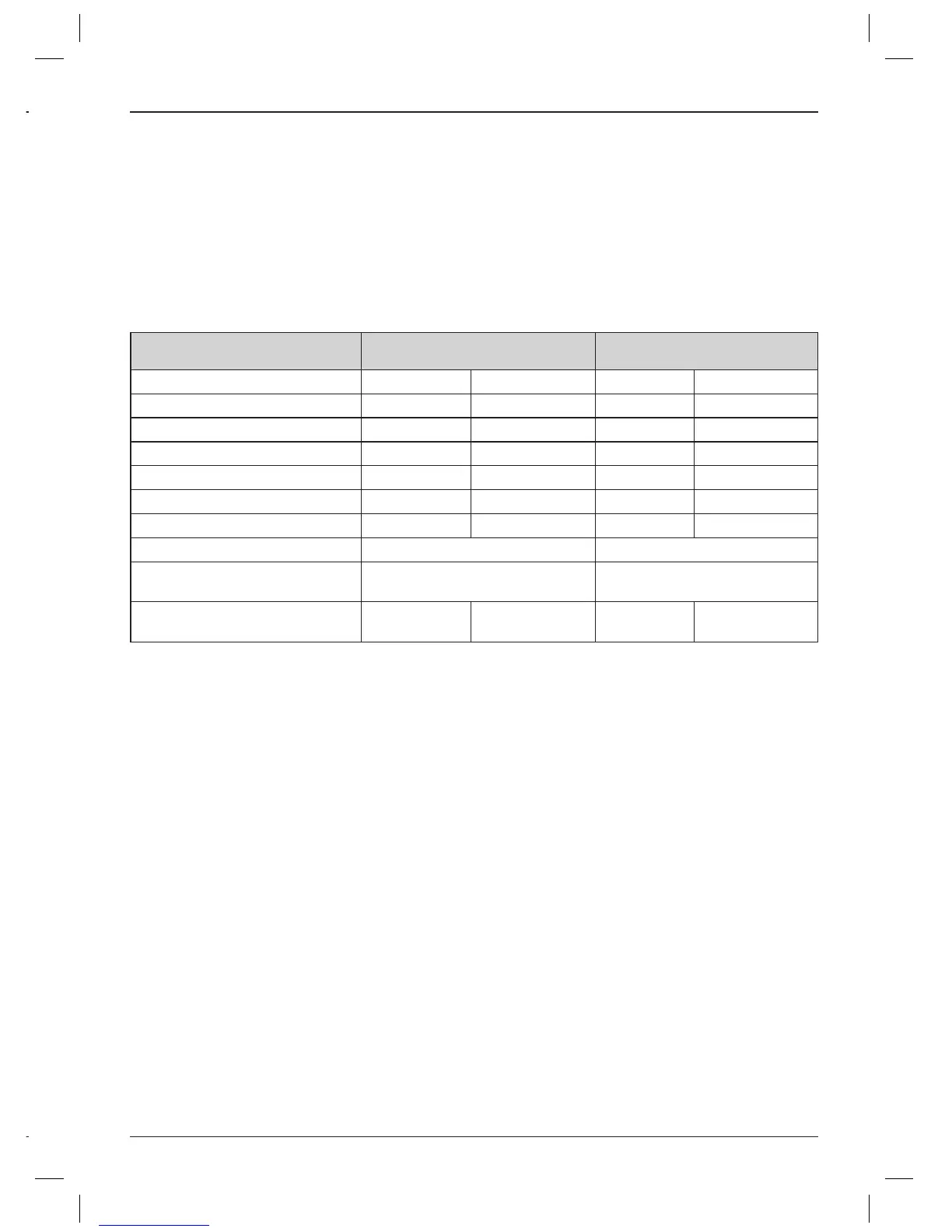

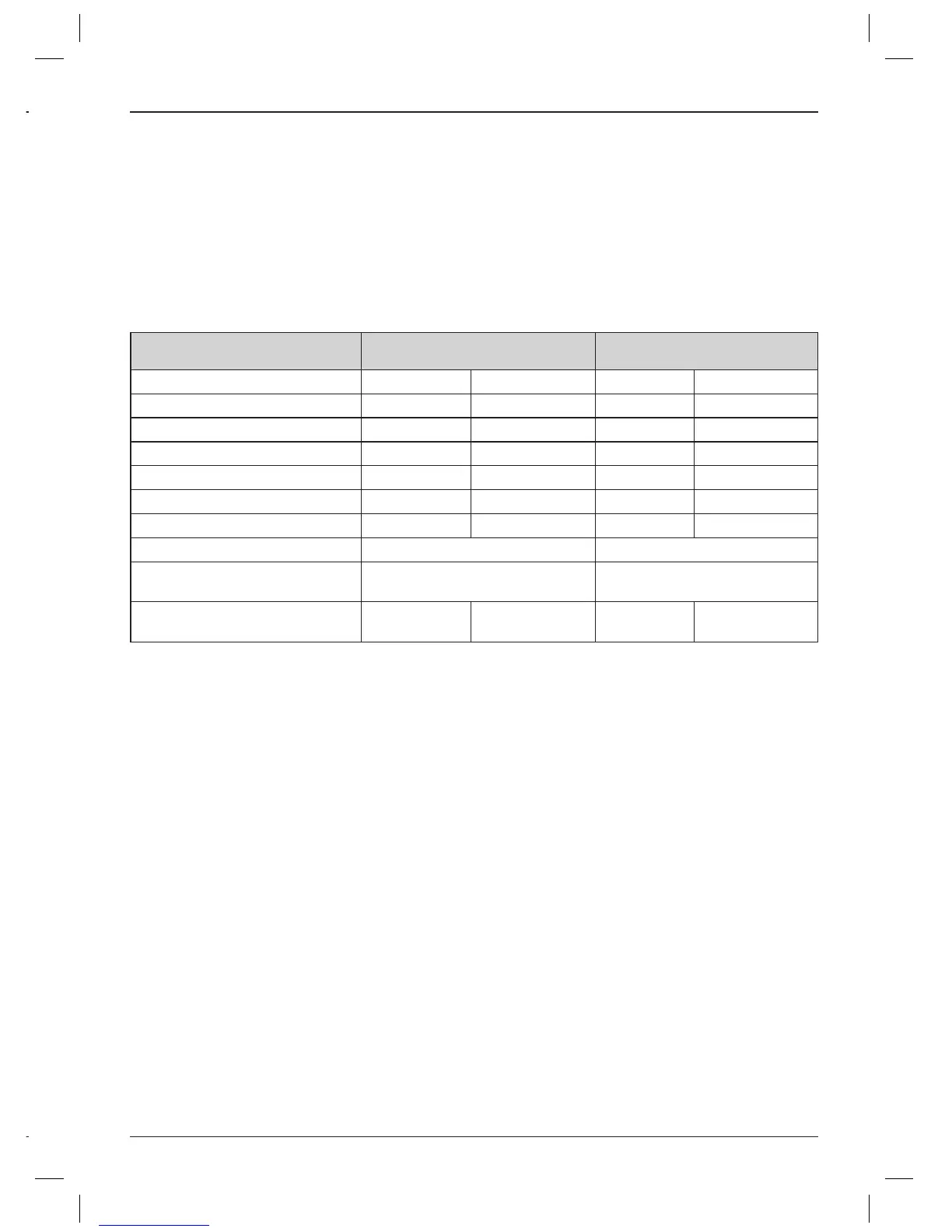

2.1. TOOL SPECIFICATIONS

XT1 XT2

Pull-Force: @5.5 bar 6.5 kN 1461 lbf 8.9 kN 2001 lbf

Air Supply Pressure: Min. to Max. 5.0 – 7.0 bar 72.5 – 101.5 lbf/in

2

5.0 – 7.0 bar 72.5 – 101.5 lbf/in

2

Oil Pressure: Pull @ 5.5 bar 160 bar 2320 lbf/in

2

210 bar 3045 lbf/in²

Stroke: Minimum Piston Stroke 17.8 mm 0.7 in. 19.8 mm 0.79in.

Weight: Incl. nose equipment 1.17 kg 2.58 lb 1.26 kg 2.78 lb

Weight: without nose equipment 1.07 kg 2.36 lb 1.15 kg 2.54 lb

Free Air Volume: @ 5.5 bar 1.5 ltr 91.5 in

3

2.2 ltr 134.2 in³

Cycle Time: Approximate 0.4 seconds 0.6 seconds

Noise Level:

Uncertainty noise: k = 3db(A)

77.95 dB(A) 77.1 dB(A)

Vibration Level: Uncertainty

vibration: k = 0.1 m/s

2

<2.5 m/s

2

<8.2 ft/s

2

<2.5 m/s

2

<8.2 ft/s

2

Loading...

Loading...