Supported Instructions and File Types

QB Expert Alpha Controller

160

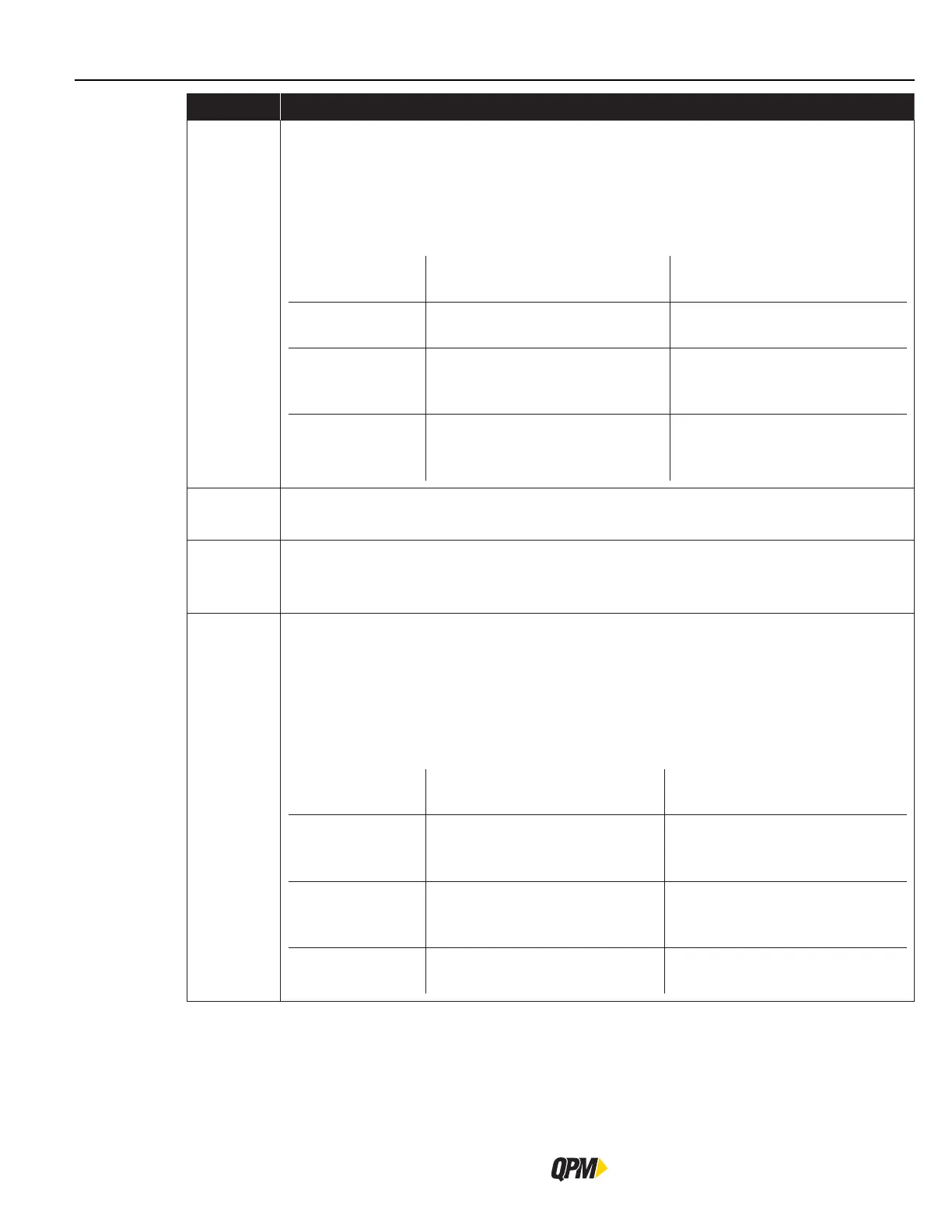

Instructions Description

RTO

Retentive Timer

Use the RTO instruction to turn an output on or off after its timer has been on for a preset time

interval. The RTO instruction is a retentive instruction that begins to count millisecond intervals

when rung conditions become true. The RTO instruction retains its accumulated value when the

rung conditions become false. The Time Base must be 10 msec. The timer will not work in any

other Time Base.

This Bit Is Set When

And Remains Set Until One of

the Following

Timer Done Bit DN

(Bit 13)

accumulated value is equal to or

greater than the preset value

the appropriate RES instruction is

enabled

Timer Timing Bit

TT (Bit 14)

rung conditions are true and the

accumulated value is less than the

preset value

Rung conditions go false or when

the done bit is set

Timer Enable Bit

EN (Bit 15)

rung conditions are true

rung conditions go false or if

the timer is reset with the RES

instruction

SOR

Start of Rung

Marks the beginning of a new rung.

SUB

Subtract

Use the SUB instruction to subtract one value (source B) from another (source A) and place the

result in the destination.

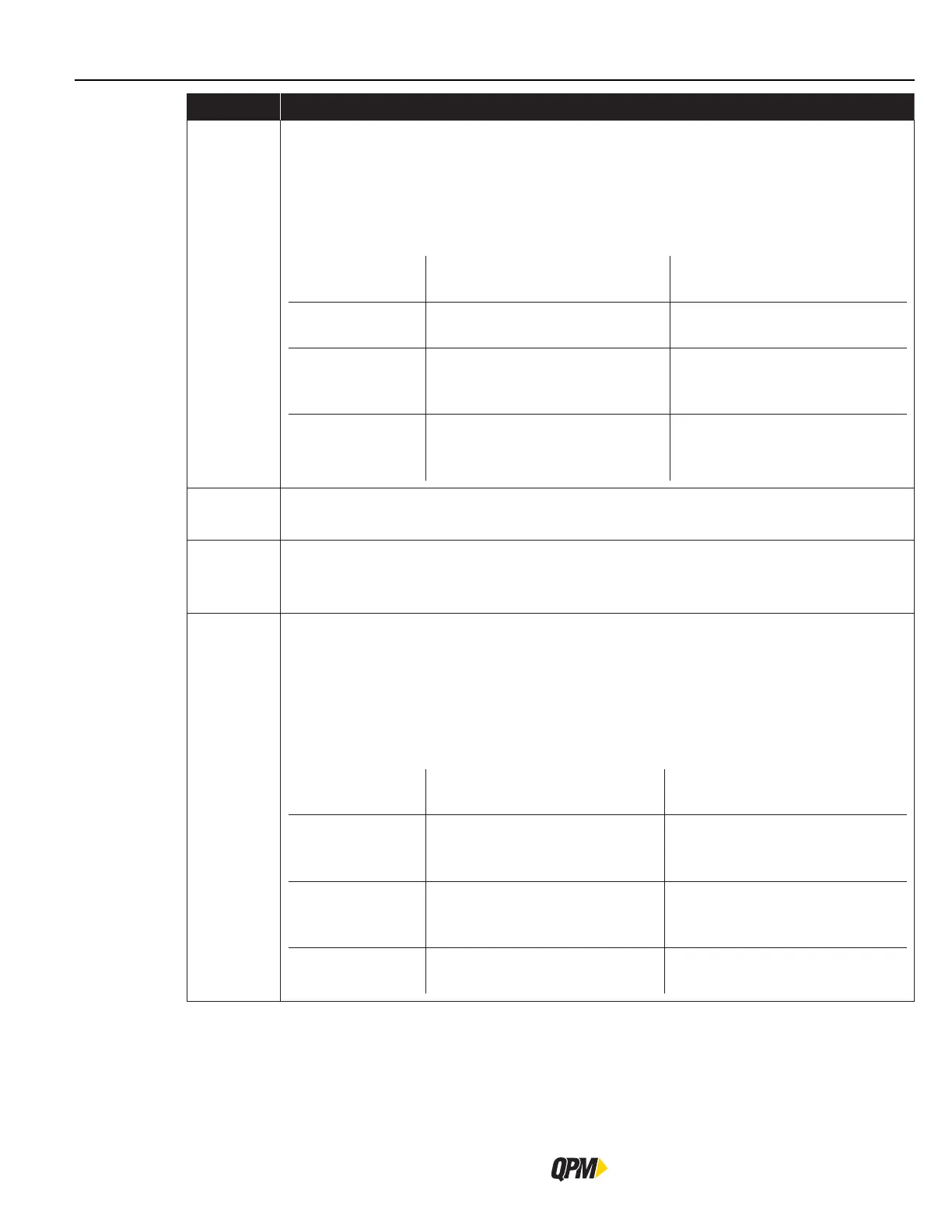

TOF

Timer Off Delay

Use the TOF instruction to turn an output on or off after its rung has been off for a preset

time interval. The TOF instruction begins to count millisecond intervals when the rung makes

a true-to-false transition. As long as rung conditions remain false, the timer increments

its accumulated value (ACC) each millisecond until it reaches the preset value (PRE). The

accumulated value is reset when rung conditions go true regardless of whether the timer has

timed out. The Time Base must be 10 msec. The timer will not work in any other Time Base.

This Bit Is Set When

And Remains Set Until One of

the Following

Timer Done Bit DN

(Bit 13)

rung conditions go false and the

accumulated value is greater than

or equal to the preset value

rung conditions are true

Timer Timing Bit

TT (Bit 14)

rung conditions are false and the

accumulated value is less than the

preset value

rung conditions go true or when

the done bit is set

Timer Enable Bit

EN (Bit 15)

rung conditions are false rung conditions go true

Loading...

Loading...