Maintenance

Before performing any maintenance to the crane, consider the following:

• Only qualified service personnel are to perform maintenance on the

crane. Never modify or alter any of the equipment, whether mechanical, electrical, or

hydraulic, without explicit approval from Stellar Industries.

• Position the crane where it will be out of the way of other operations or vehicles in the

area.

• Lower the boom fully or stow in the cradle to prevent uncontrolled movement.

• Place all controls in the off position and secure operating features from inadvertent

motion.

• Before any service or repair is performed, shut off the engine.

• Before performing any maintenance on electrical components, disconnect the power

source.

• Before performing any maintenance on hydraulic components, relieve hydraulic oil

pressure from all hydraulic circuits. Move pedals and control levers repeatedly through

their operating positions to relieve all pressures.

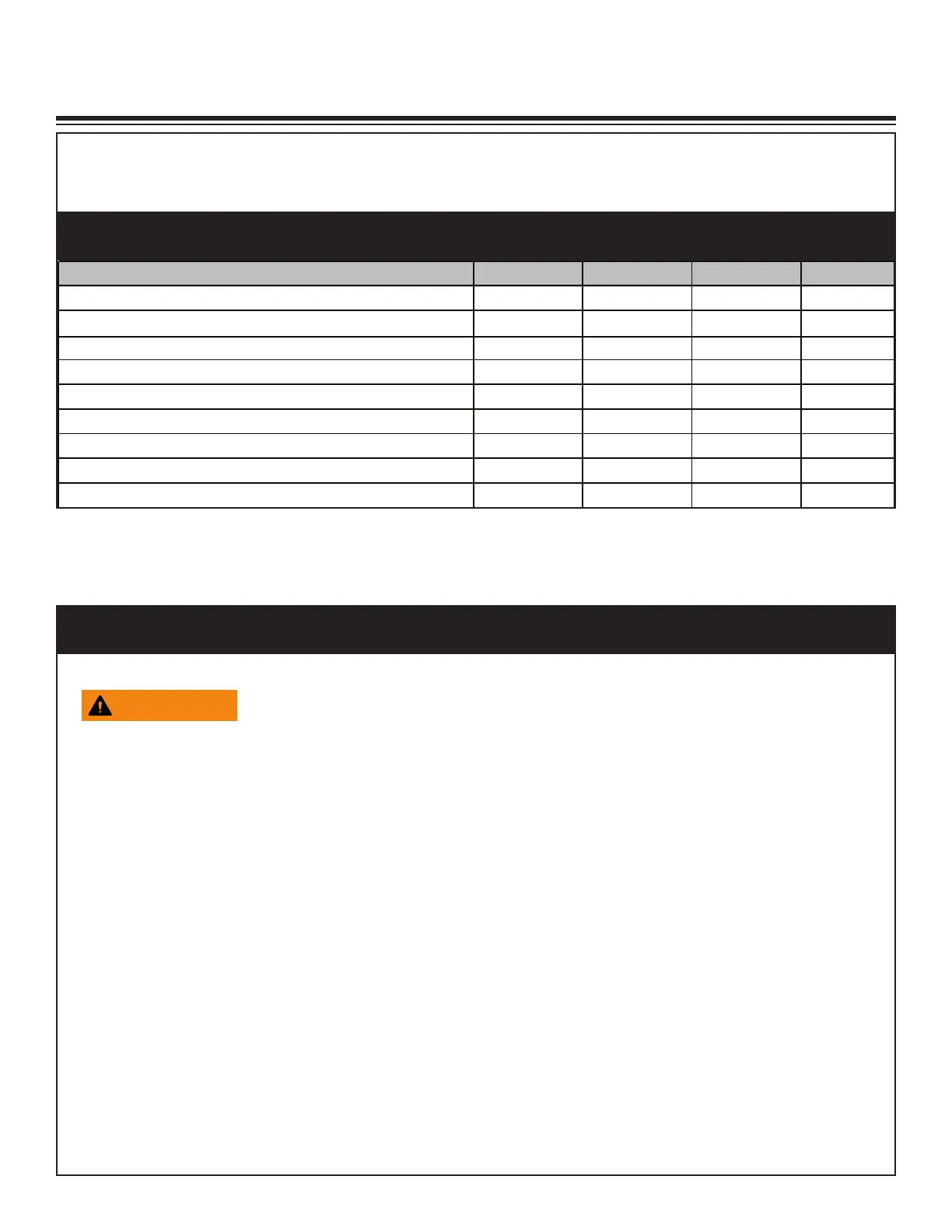

Chapter 2 - Maintenance

General Maintenance Guidelines

Maintenance Operation Daily Weekly Monthly Hourly

Check hydraulic reservoir oil level. X

Grease rotation gear inner race bearings. X

Grease rotation gear worm drive bearings. 3 months

Grease rotation gear open gear teeth. X

Grease all cylinder pivot points. X

Lubricate extension booms. X

Check winch gear grease level. X

Drain and replace hydraulic oil. 6500

Tighten all hydraulic lines. 6 months

* For a more detailed outline of scheduled inspection points, refer to the Stellar® Crane Inspection Log. The

Stellar® Crane Inspection Log is an essential guide for the daily, monthly, quarterly and annual inspection

tasks that will help maintain the quality of your Stellar product.

Maintenance is an important part of extending the life of any Stellar

®

Telescopic Crane.

Performing key maintenance items on a scheduled program will prevent unnecessary

downtime.

Basic Crane Maintenance Schedule*

Loading...

Loading...