Maintenance

Rotation Gear Bearing Maintenance

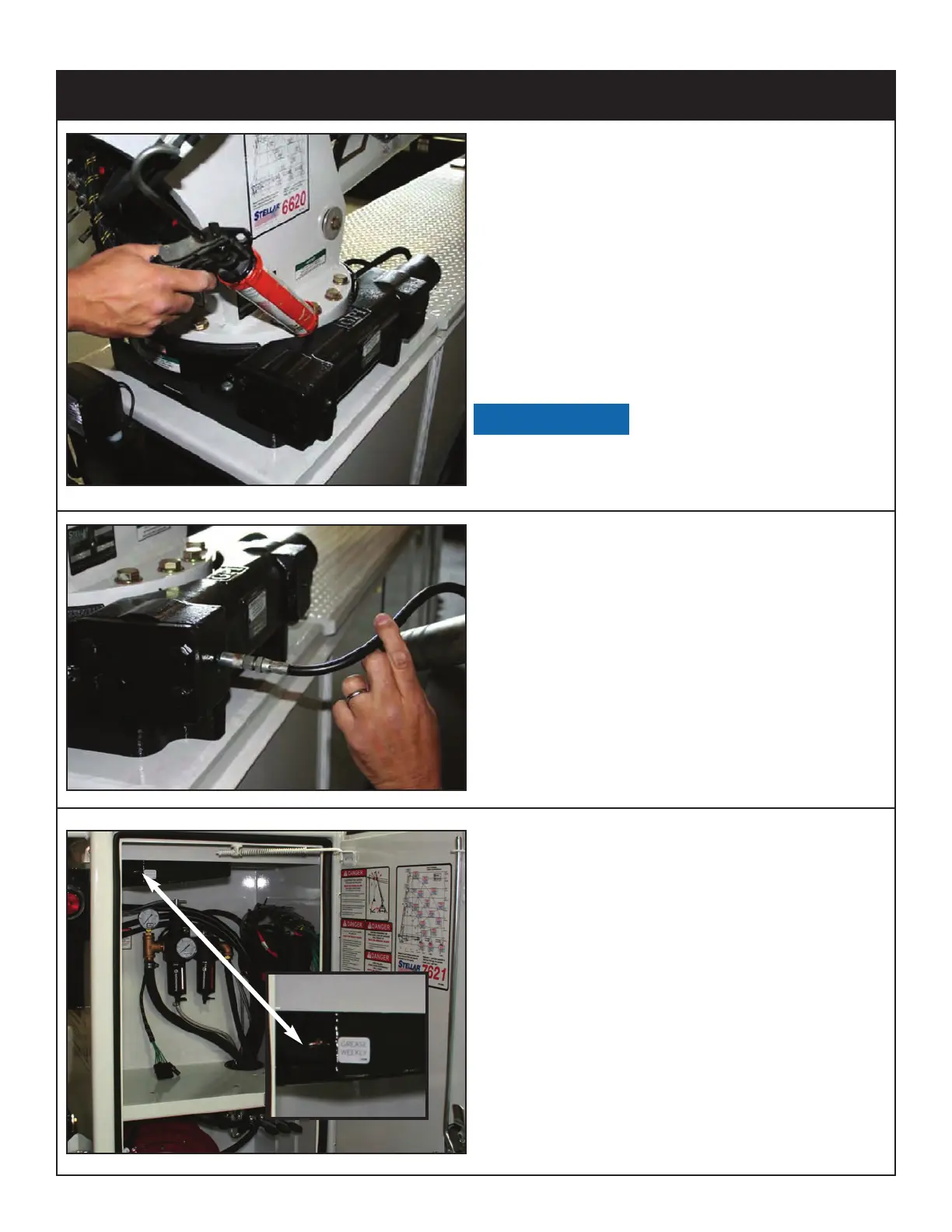

Rotation Worm Gear and Open Gear Teeth

Use a heavy Moly Lube grease (Stellar PN

4460) to lubricate the worm gear and open

gear teeth of the rotation bearing. Slowly

rotate the crane while pumping the grease

between the worm and rotation gear. This

should be greased every month or sooner

depending on the usage of the crane.

Another way of applying the grease would

be to remove the gear guard and brush the

Molube grease between the gear teeth of

the rotation bearing.

Do not lubricate the worm

and rotation gear teeth with EP2 grease. EP2

grease will wipe the Molube grease clean

causing excessive wear.

Worm Gear Bearings and Races

Apply three (3) pumps of EP2 grease to the

two grease zerks located on the side of the

Rotation Gear bearing; every three months.

After adding the EP2 grease, rotate the

crane fully.

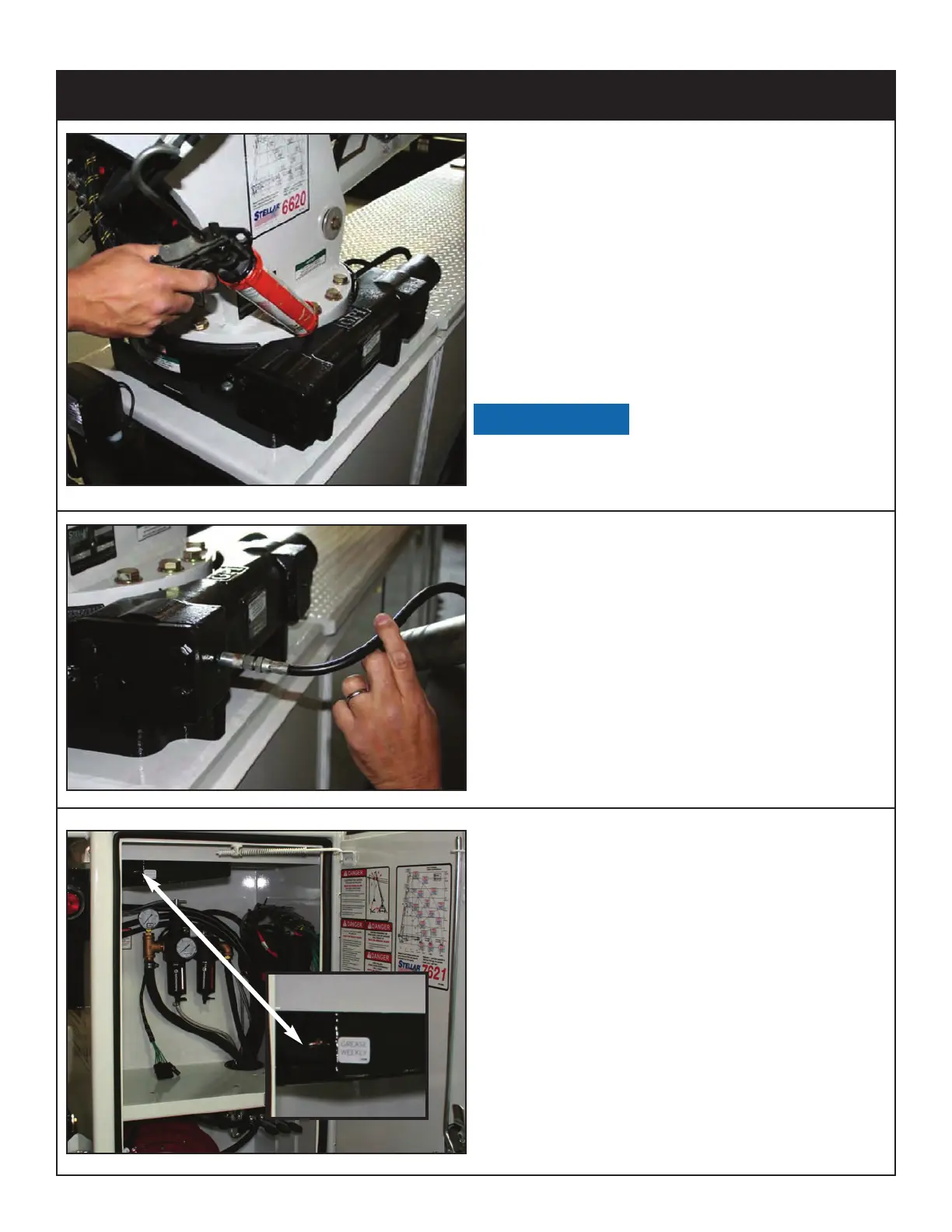

Inner Gear Bearing Race

To lubricate the inner race of the large rota-

tion gear bearing, open the compartment

door just below the crane. The grease zerk

for the inner race bearing is located on the

compartment drip tray. The inner race will

need to be lubricated with EP2 Grease

weekly. The first week grease the inner race

bearing at the one (1), three (3), five (5),

seven (7), nine (9), and eleven (11) o’clock

positions. The following week, grease the

inner race bearing in the two (2), four (4), six

(6), eight (8), ten (10) and twelve (12)

o’clock positions. Rotate lubrication points

every week.

Loading...

Loading...