stewmac.com

12

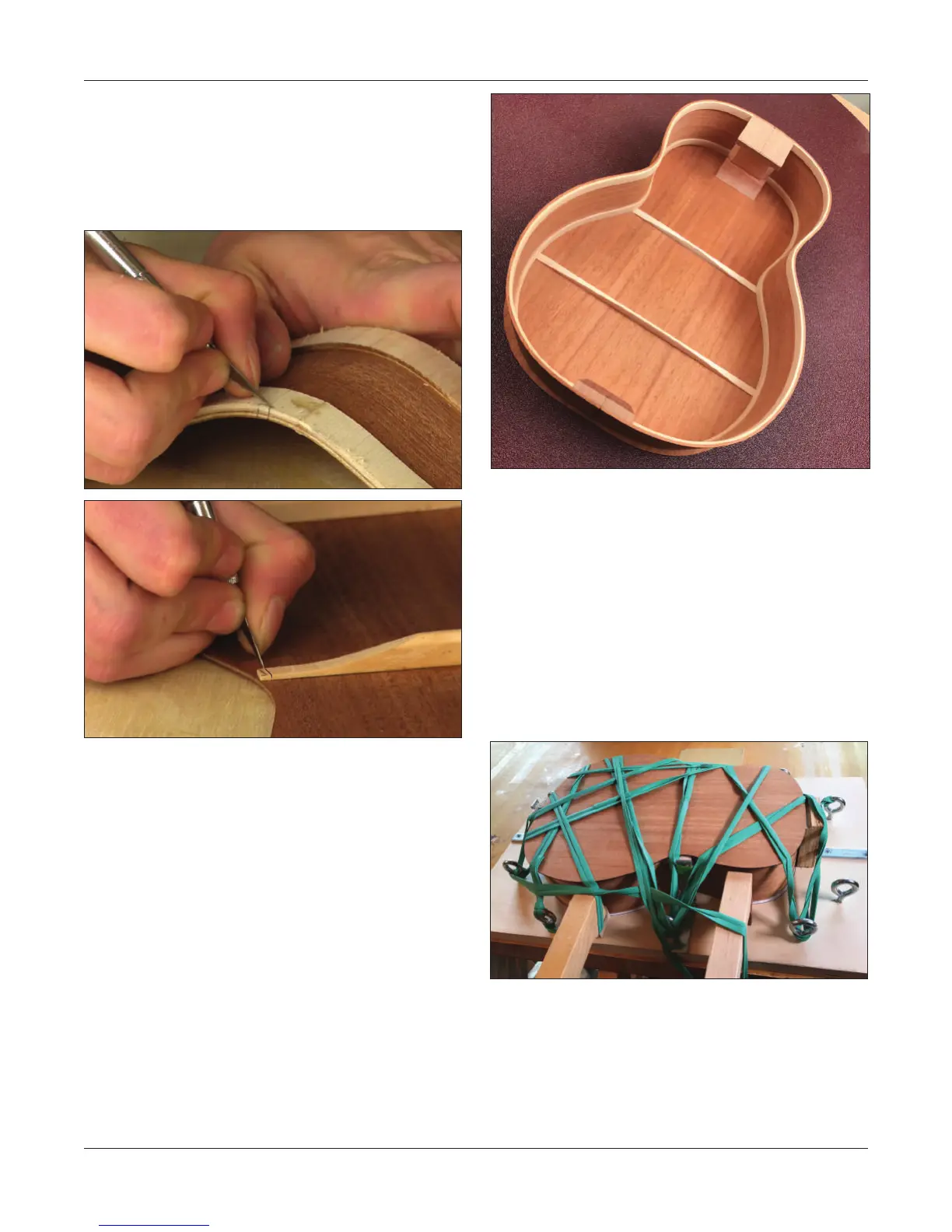

With a sharp razor knife, cut notches in the linings for the

braces. A small chisel is helpful for chipping out the notch.

Trim the ends of the braces so they t within the sides,

dropping into the notches. Scrape the trimmed brace ends

o the back. When you’re done, the back ts at onto the

sides, with the braces keyed into the notches.

The top and back are slightly oversize, with edges that hang

over the sides. This overhang will be removed after gluing.

Glue the back on the rim

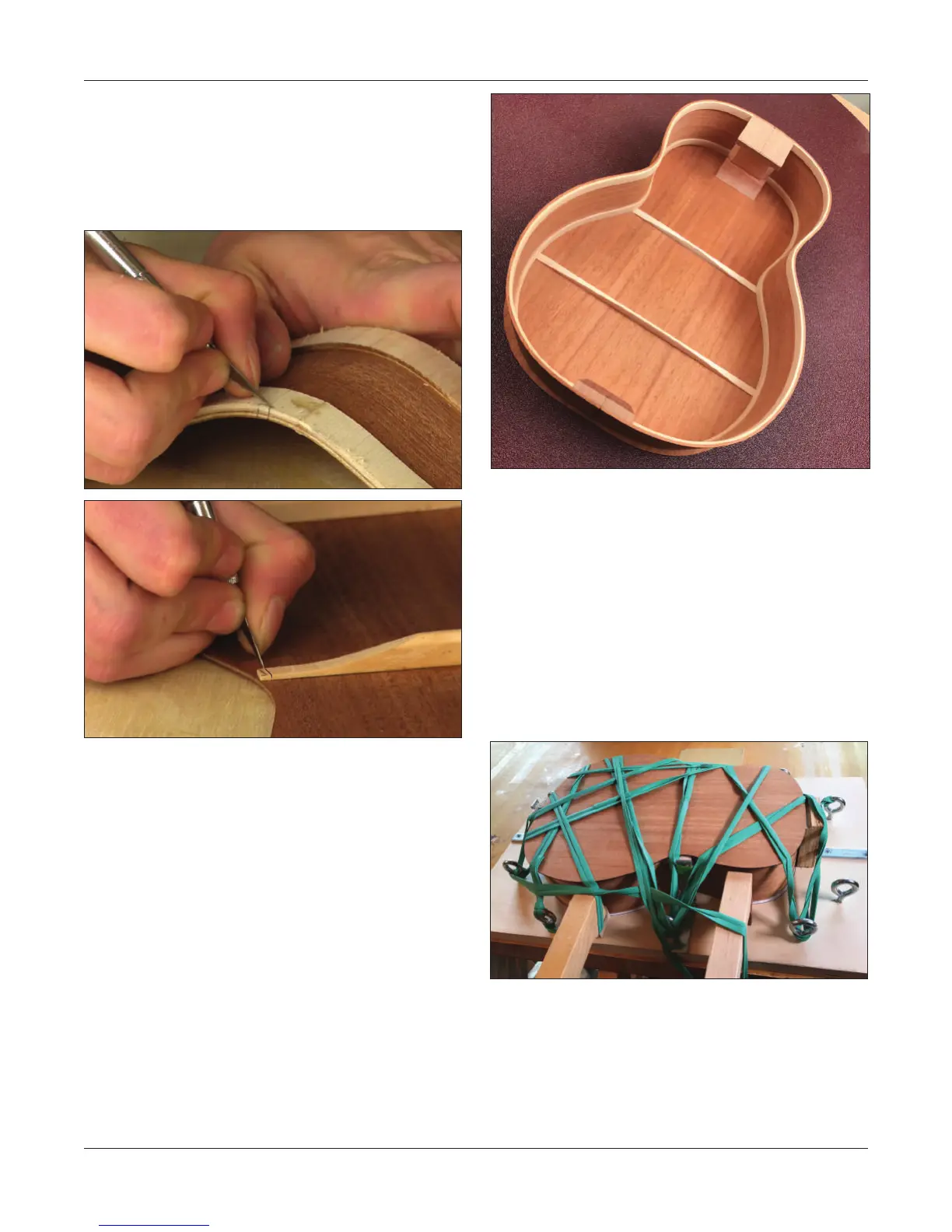

To get good clamping pressure all around the back, the

body mold is now put to use again. By adding screw eyes

or hooks around the edges of the of the plywood, you can

ax the rubber clamping bands included with your kit. If

your clamping band is an unbroken loop, cut it to make it

one long strip.

Tie the end of the clamping band and stretch it tightly over

the body to the opposite corner. Continue strapping from

corner to corner until the back is clamped under a web of

rubber bands. Tie o the end to one of the screw eyes. Try

this as a dry run.

When you’re ready for glue, apply it to the edge of the side

and lining, and to the end of the neck and tail blocks. Put the

back in position and wrap with the rubber clamping band.

Let the glue dry for 2 hours, then remove the body from

the mold. Clean away any dripped glue, especially where it

can be seen through the soundhole of the assembled body.

Loading...

Loading...