WORKSHOP MANUAL

4 - MAINTENANCE

EDITION

PAGE

20 /37

4. The blade locking

device has been trig-

gered with the blades still

rotating

• Malfunction of the lock-

ing devices

Replacement of the locking device and

adjustment of the cable

Cable breakage

5. The blades rotate in

the maintenance/wash

position

Cable not adjusted Replacement of the locking device and

adjustment of the cable

Cable breakage

6. Abnormal vibration

and / or irregular cutting

Loose parts. Tighten all fastening devices

Tightening torque

Damaged cutting means. Sharpening and balancing the blades

Check the alignment of the blade shafts

7. No cutting height ad-

justment

Electric motor malfunc-

tion

Check electric connection

Replace the electric motor

Damaged tie rods Replacement and adjustment of the tie

rods

Tie rods not adjusted

8. Swivel wheels locked Worn parts Replace worn parts

Impacts with foreign

parts

Replacement of bushings

Replace damaged parts

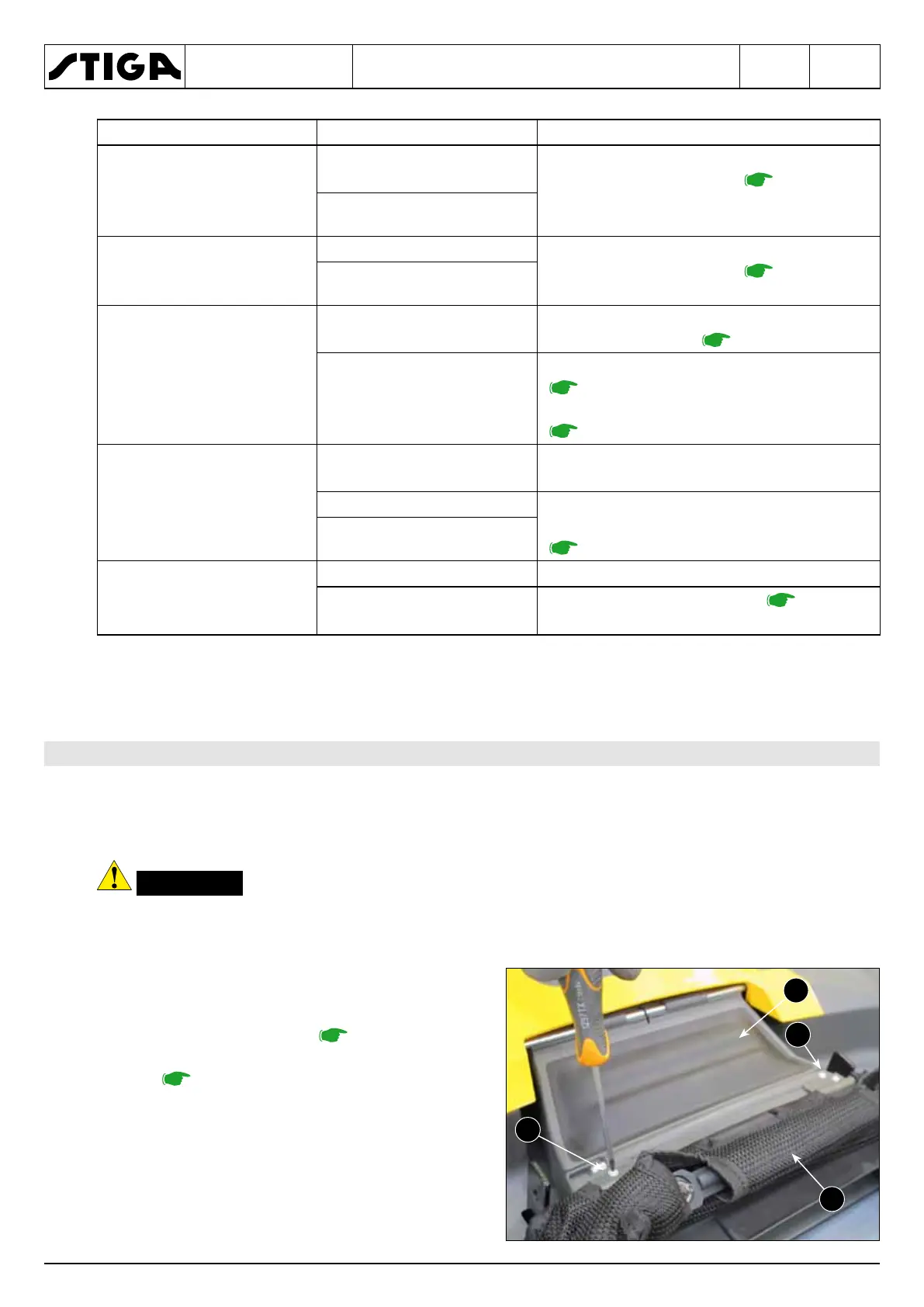

- The integrity of the belt guard canvas is an essential condition for the

safety of the machine and equipment. Always replace the canvas at the first signs of wear

or tear.

Remove the cutting deck from the machine, fol-

lowing the following procedures in reverse order:

• Disconnect the PTO belt.

from 3 to 1.

• Remove all mechanical and electrical connec-

tions.

from 8 to 1.

1. Undo the two screws (1) that fasten the canvas

belt guard (2) to the intermediate guard (3).

Loading...

Loading...