1.6

Service

Each new machine is supplied with a serv-

ice book. The service log should be

stamped at every service carried out by an

authorised workshop. The service book is

part of an active aftermarket program and

must be stored in a safe place during the

lifetime of the machine. The service book

must accompany the machine if it is sold as

used.

The service points are given in the table

below. Descriptions of how the proce-

dures are to be carried out are given after

the table.

WORKSHOP MANUAL

TITAN

Chapter

1 - General instructions

EDITION

2018

Page

9

Service point

Hours of operation/Calendar

months

See the

instructions

1st time Interval

Water separator, check 50/-

in the

instructions for

use paragraph

maintenance

Filter in water separator, cleaning

Fuel filter, replace 400/-

Tyre pressure, check, adjust

Engine oil, filter, change 50/12 200/12

Hydraulic oil, change/clean 400/12

Wheel motors , change oil 50/12 200/12

Belt transmissions, check 50 200/-

Cooling system, change coolant 1000/24

Battery, check 50/-

Air filter, clean pre-filter 200/-

Air filter, change inner filter 200/-

Lubrication 50/-

Tightening / control of hydraulic cou-

plings and hydraulic tubes

50 50/-

Adjusting valves 1000/-

Grinding valves 2000/-

Tank venting valve, change/ clean 1000/24

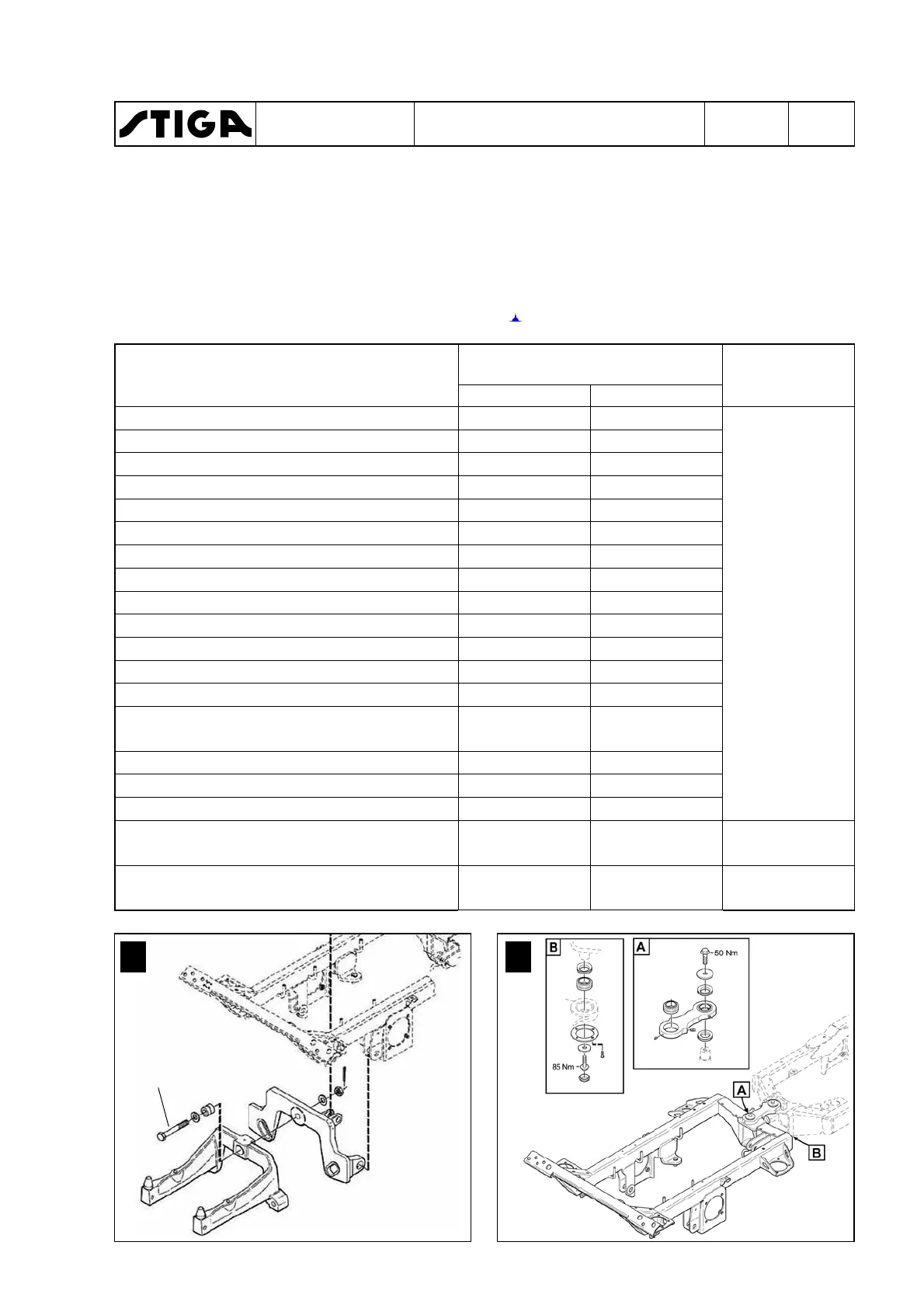

Check the correct tightening of the fix

screw of the lift arms support

50/12 400/12

See the

drawing (1)

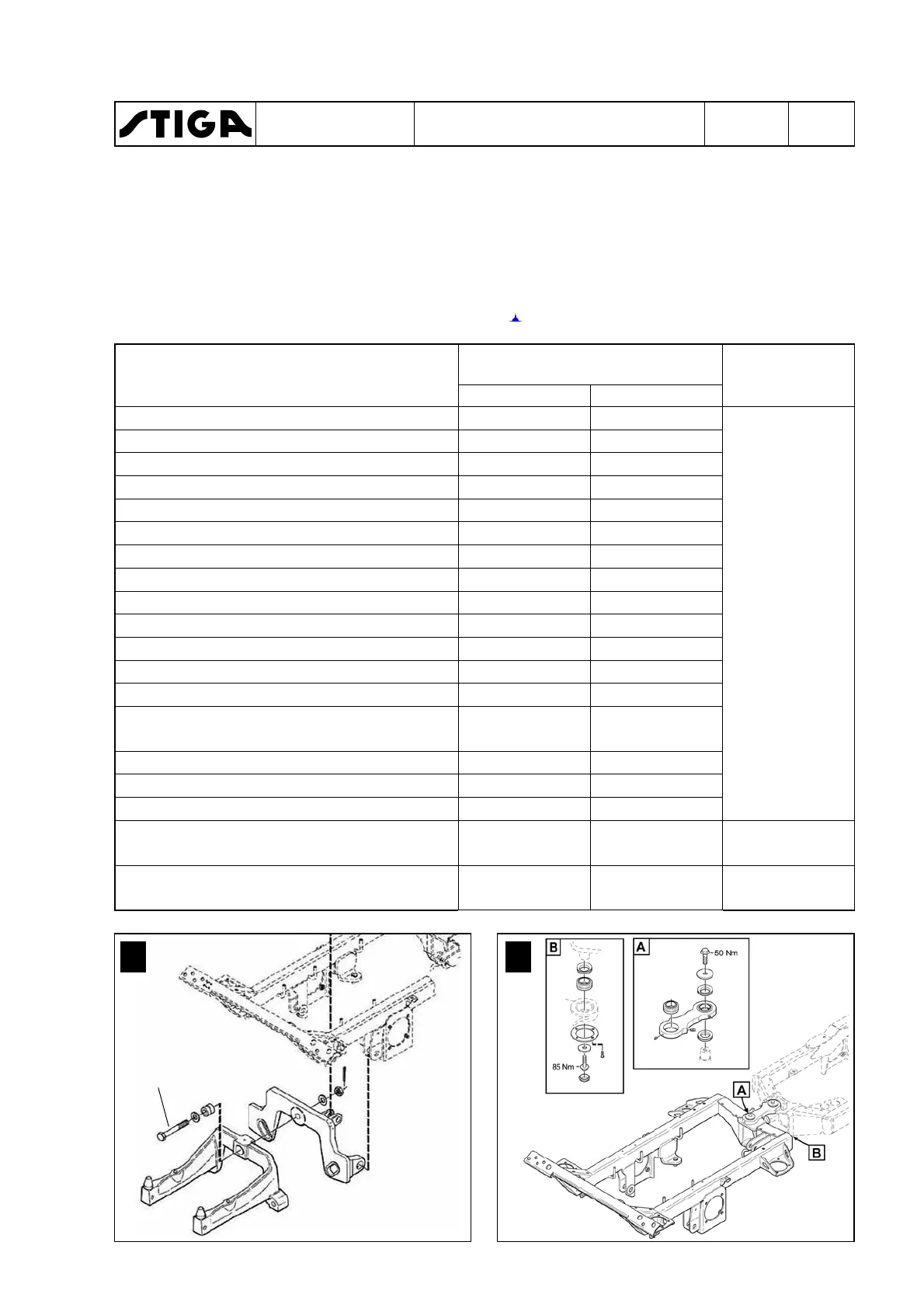

Check the tightening torque of the

screws (A) and (B) of the joint.

50/12 400/12

See the

drawing (2)

1 2

ATTENTION

Correct torque

385 Nm

Loading...

Loading...