Series 4180 Powerhead 27

N Start the engine and warm it up at varying speeds for

1 minute – if necessary, turn the idle speed

screw (LA) slowly clockwise until the engine runs

smoothly – the attachment must not run.

N With the engine idling, turn the low speed screw

L) (13) counterclockwise or clockwise until maximum

engine speed is obtained.

The maximum engine speed should be between 3,100

and 3,300 rpm.

N Use the idle speed screw (LA) (12) to set the engine

idle speed to 3,200 rpm.

N With the engine idling, turn the low speed screw (L)

(13) counterclockwise and set the engine speed to

2,800 rpm.

11.2.2 Adjusting Idle Speed

Engine stops while idling

N Start and warm up the engine.

N Turn the idle speed screw (LA) (12) clockwise until

the engine runs smoothly – the attachment must not

run.

Attachment runs while engine is idling

N Turn the idle speed screw (LA) (12) counterclockwise

until the attachment stops moving and then turn the

screw about another 1/2 to 3/4 turn in the same

direction.

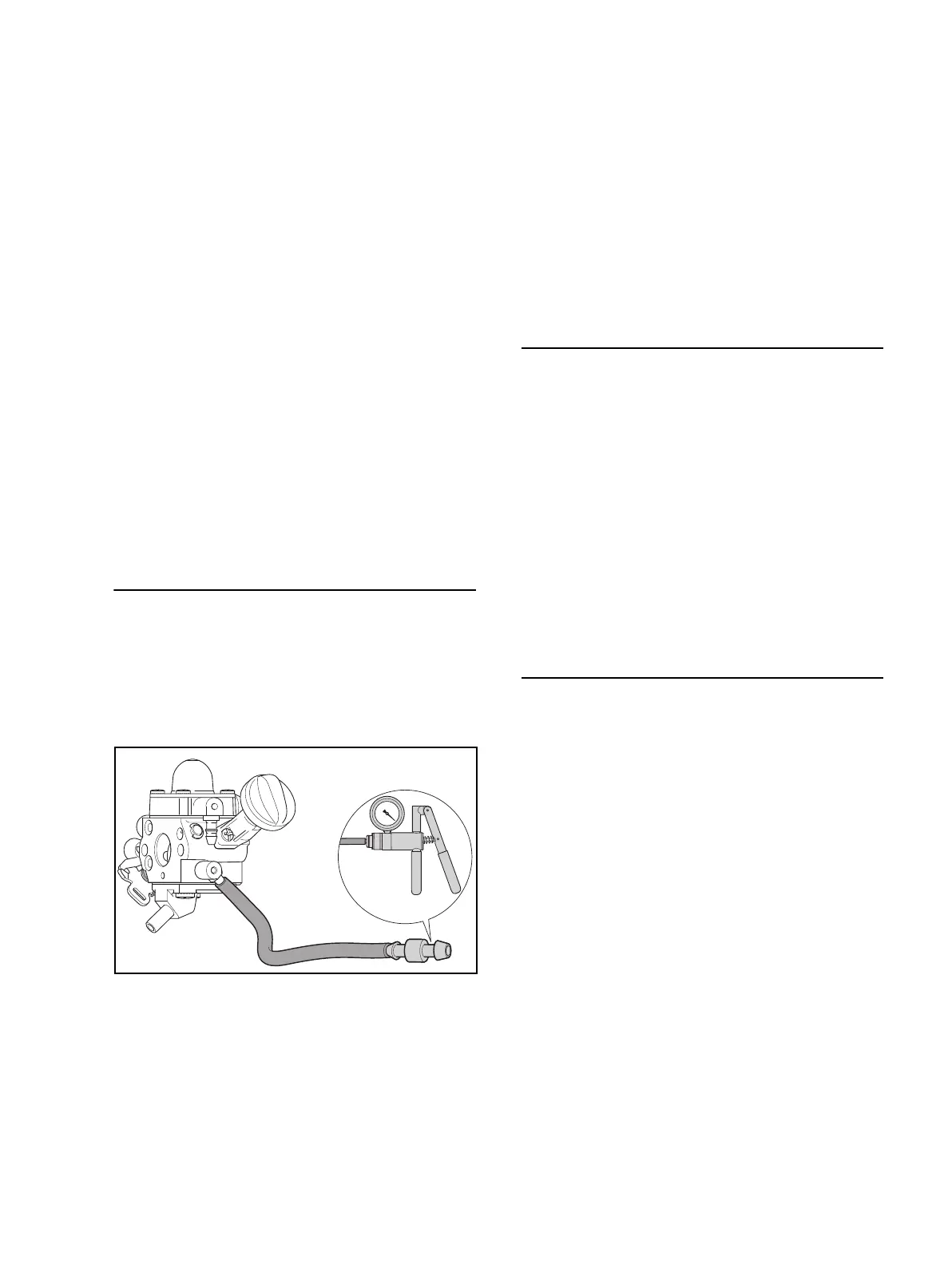

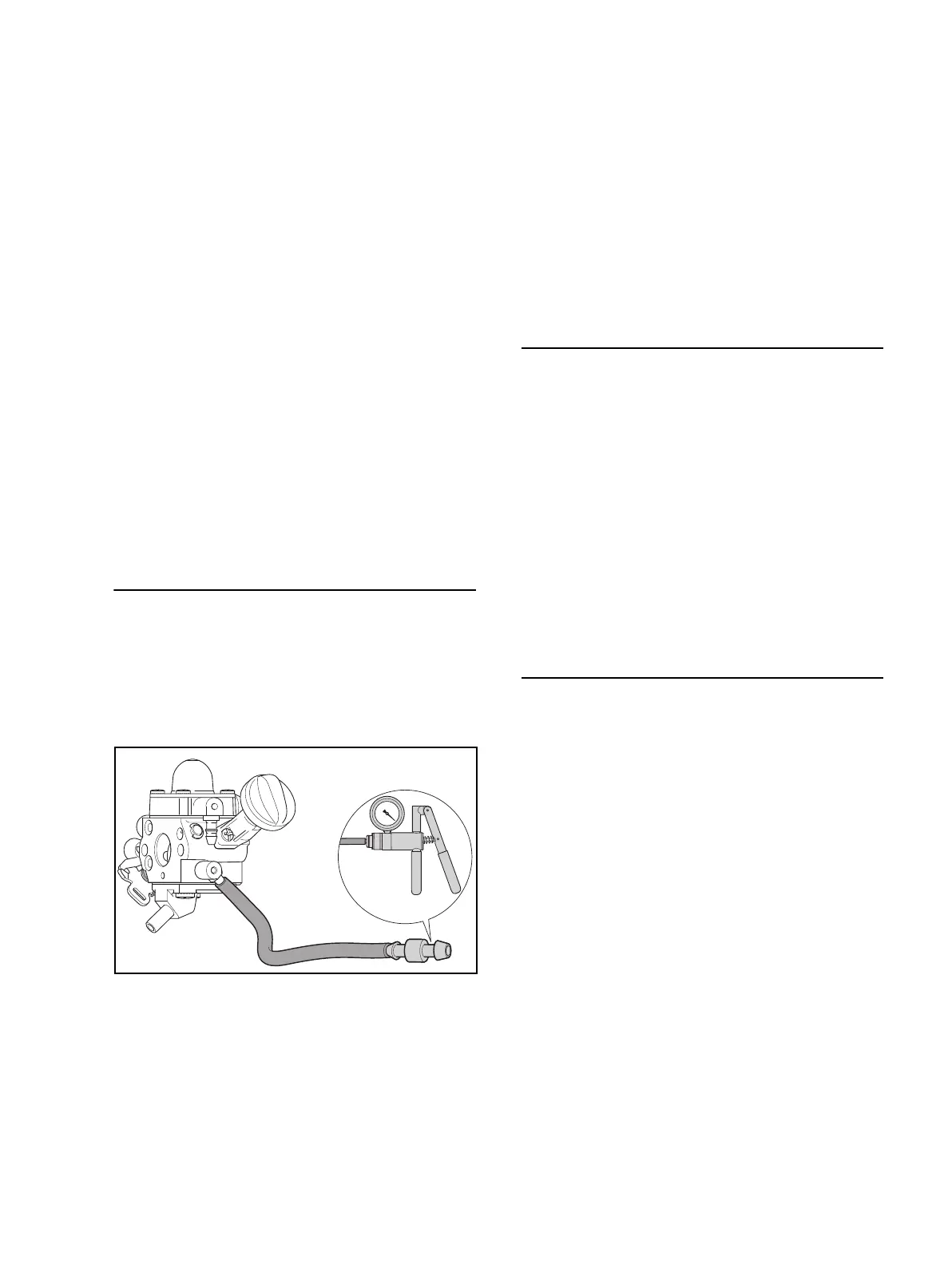

11.3 Testing Carburetor for Leaks

In the case of problems with the carburetor or fuel supply

system, also check and clean or replace the tank vent, @

6.1.

The carburetor does not need to be removed for the

leakage test.

N Pull the fuel hoses off the carburetor, @ 10.2

N Push the 135mm hose 1110 141 8600 onto the

carburetor’s fuel connector.

N Fit nipple 0000 855 9201 in the 135mm

hose 1110 141 8600.

N Connect hose from pump 0000 850 1300 to

nipple 0000 855 9201.

N Push the ring on pump 0000 850 1300 to the right

(gauge pressure).

N Operate the pump 0000 850 1300 until gauge

pressure is 0.8 bar (11.6 psi).

If the pressure reading does not drop any further than 0.5

bar (7.25 psi) within 20 seconds, the carburetor is airtight.

If it drops, there are three possible causes:

– The inlet needle is not sealing (foreign matter in valve

seat, sealing cone of inlet needle is damaged or inlet

control lever sticking). Remove to clean.

– Metering diaphragm (5) is damaged, replace if

necessary.

– Pump diaphragm is damaged, replace if necessary.

After finishing the test:

N Pull the 135mm hose 1110 141 8600 off the

carburetor’s fuel connector.

N Install the carburetor, @ 10.1

11.4 Choke Knob

Removing

N Take out the screw (25) and remove along with choke

knob (24) and guide (23).

N Remove the spring (22) from the choke shaft (20).

N Pull the choke knob (24) off the guide (23).

Installing

N Slip the spring (22) onto the choke shaft (20).

N Insert the choke knob (24) in the guide (23) and rotate

it counterclockwise until it is fixed in the groove.

N Push choke knob (24) with guide (23) onto the choke

shaft (20) as far as stop.

N Insert and tighten down the screw (25).

11.5 Metering Diaphragm and Manual Fuel Pump

Removing

N Remove the carburetor, @ 10.2

N Take out the screws (1).

N Remove the bulb (3), end cover (2) and flange (4).

N Inspect the bulb (3), replace if necessary.

N Remove the metering diaphragm (5).

N Remove the gasket (6).

N Examine the metering diaphragm (5) for damage and

wear, replace if necessary. If the metering diaphragm

(5) is distorted, fit a new one.

0000-GXX-2323-A0

Loading...

Loading...