BGA 86 7

4.1 Light Emitting Diodes (LEDs) On Battery

4.2 Visual Inspection

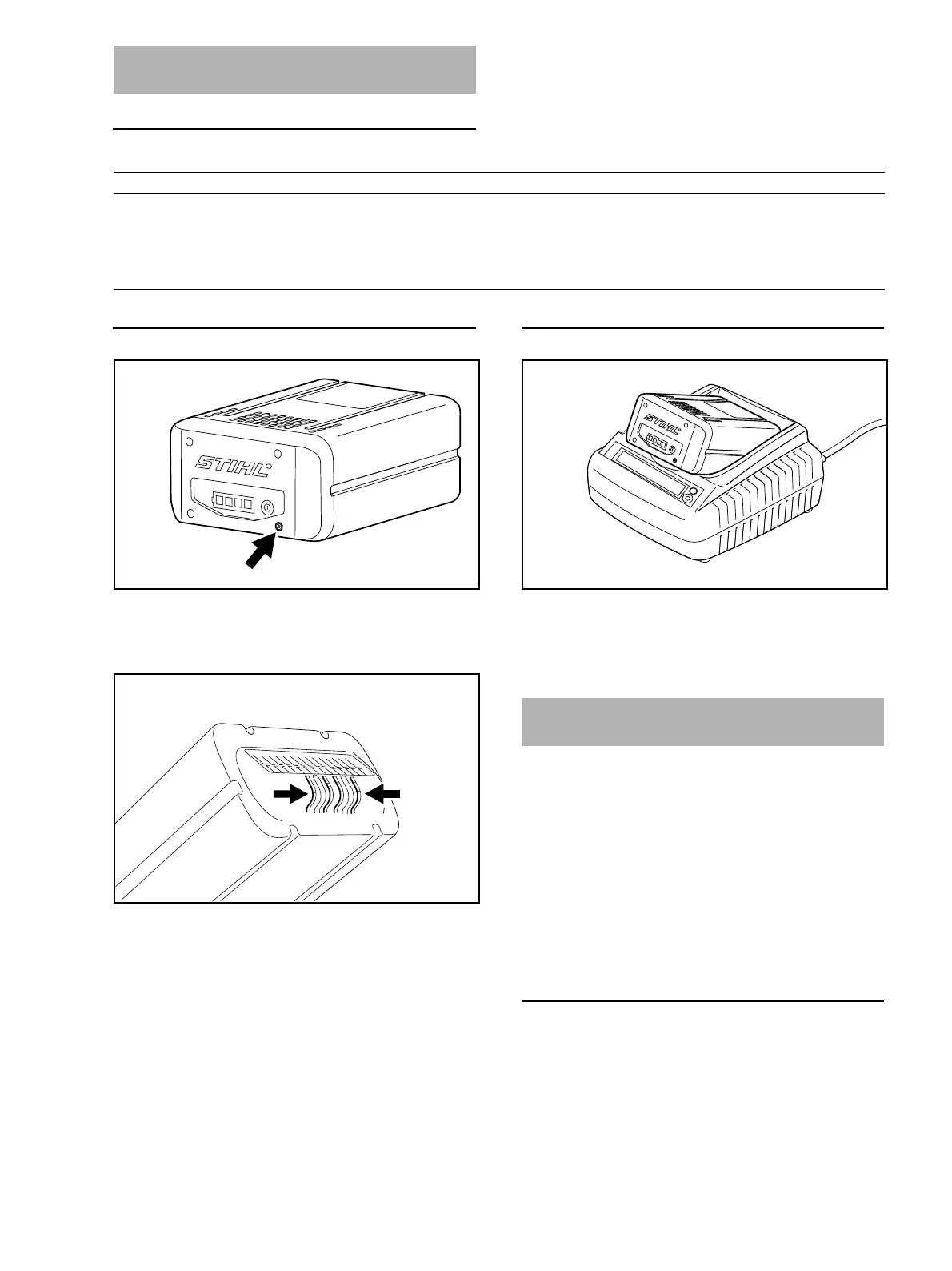

The battery is sealed (arrow) when it leaves the factory.

Never attempt to open or repair the battery.

Always carry out a visual inspection first.

N Check the contacts (arrows)

If there are signs of external damage (e.g. bent or

damaged contacts, deformation, cracks in housing),

always install a new battery.

4.3 Testing With ADG 1 Battery Analyzer

N Test the battery with the STIHL ADG 1 battery

analyzer, see separate instruction manual for ADG 1.

Always replace a defective battery.

N Observe safety precautions, see. @ 2

The electrical components of all STIHL battery power

tools with an EC motor can be tested with the STIHL

ADG 2 analyzer.

A battery bag and a suitable geometrically matching

STIHL battery with a minimum charge of 80% are required

to test the power tool.

WARNING!

The power tool's motor starts during the test. Before

starting the test, exclude any risk of injury or damage to

property from the power tool's airstream – risk of

accidents.

5.1 Visual Inspection

Always carry out a visual inspection first.

Replace damaged parts before performing test with the

analyzer.

4 Battery

Condition Cause Remedy

1 LED on battery flashes green Insufficient state of charge Charge the battery

1 LED on battery glows red Battery too hot / too cold Allow battery to cool down / allow battery

to warm up slowly at temperatures of

about 15°C - 20°C (59°F - 68°F)

4 LEDs on battery flash red Malfunction Remove the battery and refit it

5 Testing Cordless Power Tool

Loading...

Loading...