20 FS 240 C, FS 260 C, FS 360 C, FS 410 C, FS 460 C-M

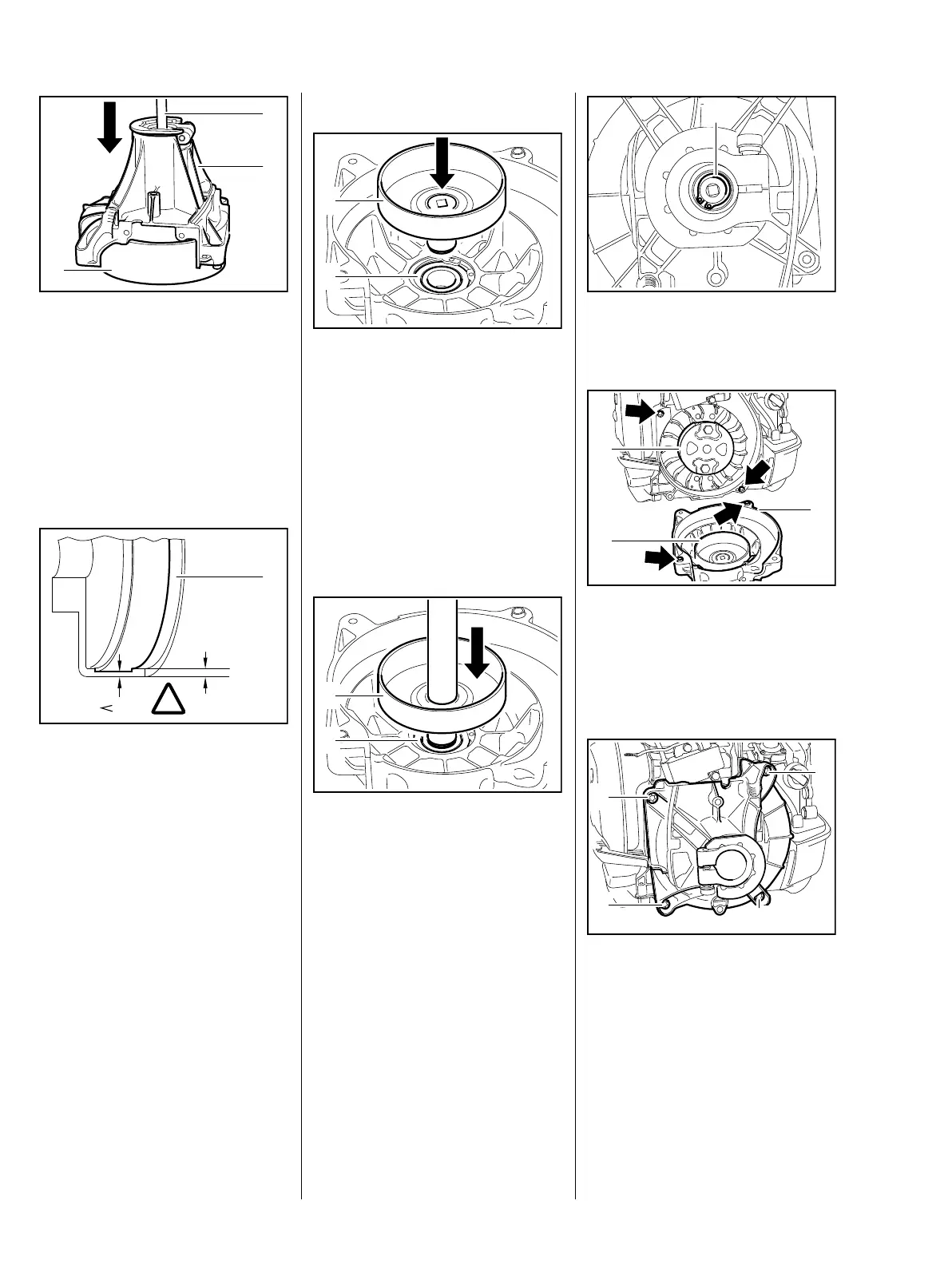

: To protect the guide sleeves, set

clutch housing (1) on ring (2)

5910 893 7005

: Orient ring (2) so that the clutch

housing rests evenly on it

: Press out clutch drum using a

suitable punch (3)

– Examine the clutch drum (1) for

signs of wear

The remaining thickness must be

measured if there are distinct signs

of wear on the inside diameter of the

clutch drum (1). The clutch drum

must be replaced if the remaining

thickness is less than approx. 80 %

of the original thickness.

If the square socket is worn or the

pin is damaged, the clutch drum

must be replaced.

5904RA006 TG

1

2

3

!

80%

100%

5902RA018 TG

1

Installation

– Heat the inner race of the ball

bearing to approx. 120 °C

(250 °F)

: Position clutch drum (1) on ball

bearing (2) and push it on as far

as it will go

This must be done quickly, as the

clutch drum absorbs heat and

begins to expand.

If it is impossible to heat the inner

race, the clutch drum must be

pressed on cold.

– Support the clutch housing on

the opposite side with a suitable

pipe on the inner race of the ball

bearing

: Position clutch drum (1) on ball

bearing (2) and press it on as far

as it will go

5904RA007 TG

1

2

5904RA008 TG

1

2

: Install circlip (1) on the opposite

side

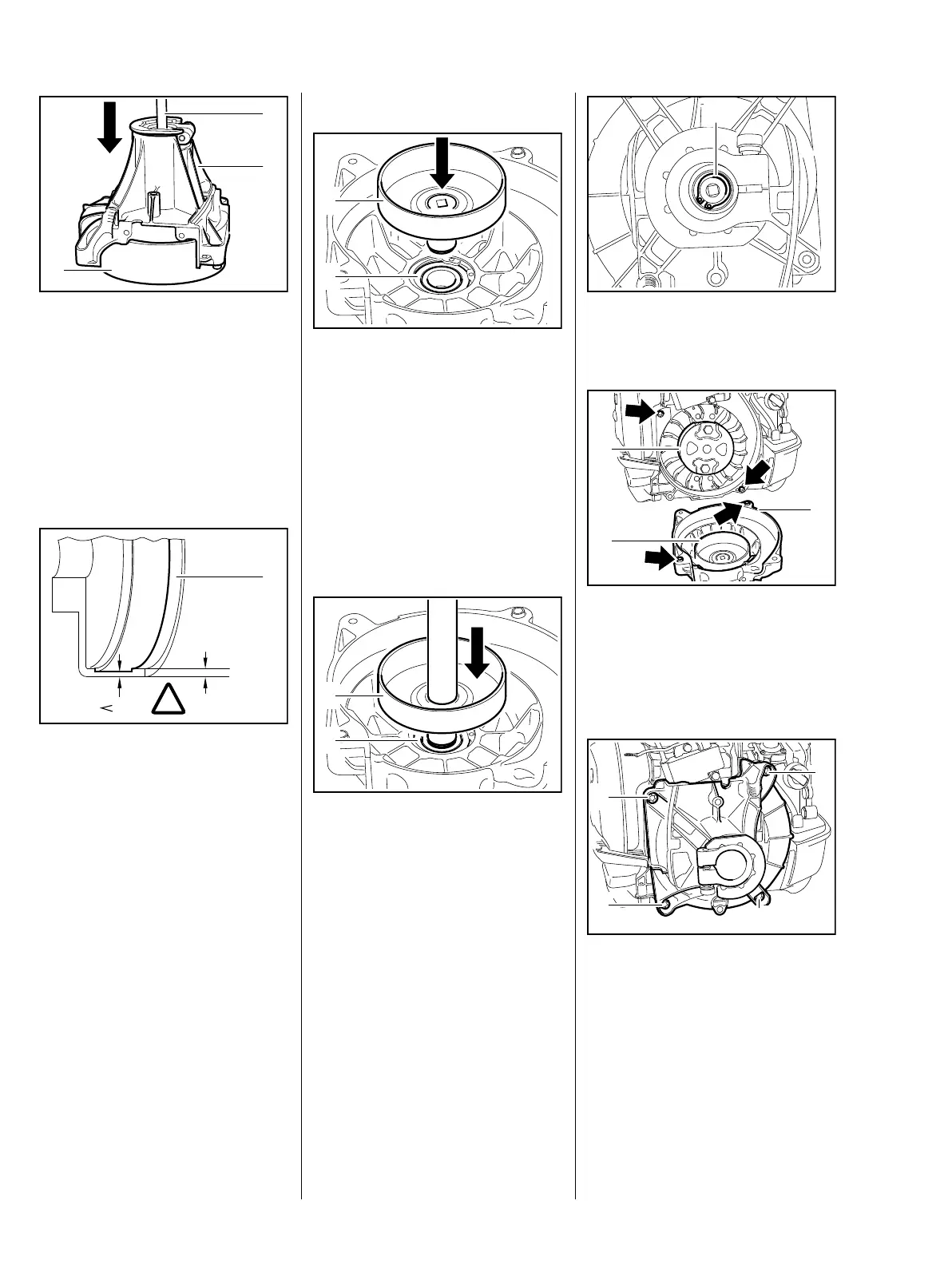

: Guide clutch housing (1) with the

clutch drum (2) over the

clutch (3) and fasten with the

sleeves in the holes (arrows) of

the clutch housing

: Insert and tighten down the

screws (1)

– Attach cable holder and short

circuit wire to engine, b 6.6.2

5904RA009 TG

3

1

2

5904RA010 TG

1

1

1

1

Loading...

Loading...