22 FS 240 C, FS 260 C, FS 360 C, FS 410 C, FS 460 C-M

4.1.1 Ball bearing

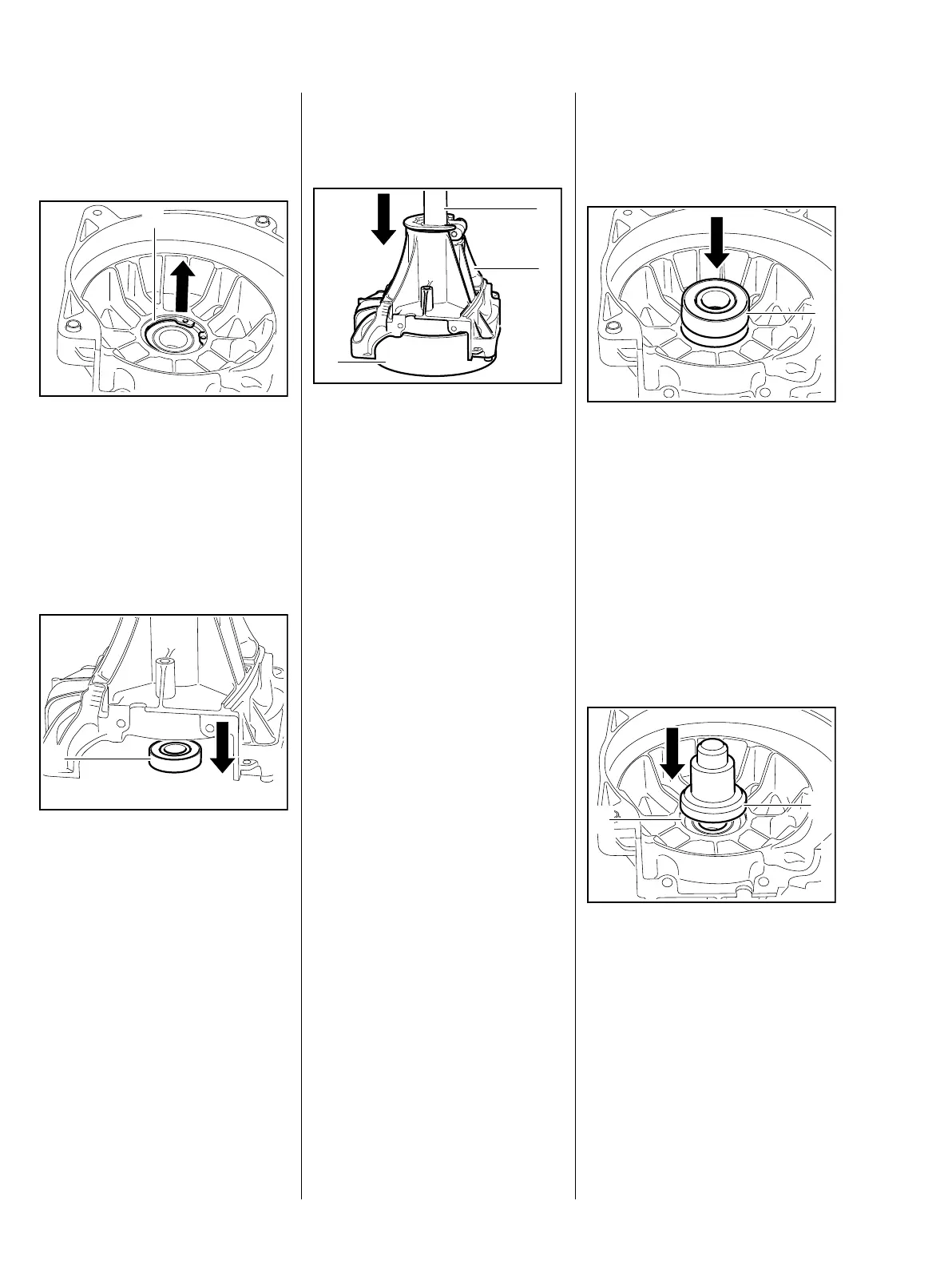

– Remove the clutch drum, b 4.1

: Remove the circlip (1)

– Remove rubber insert, b 9.1

4 -point antivibration system

– Remove both rubber buffers

– Heat the area around the bearing

seat to approx. 120 °C (250 °F)

: The bearing (1) drops out on its

own when this temperature is

reached

5904RA015 TG

1

5904RA016 TG

1

If it is impossible to heat the clutch

housing, the ball bearing must be

pressed out cold.

: To protect the guide sleeves, set

clutch housing (1) on ring (2)

5910 893 7005

: Orient ring (2) so that the clutch

housing rests evenly on it

: Press out ball bearing using a

suitable pipe (3)

– Replace ball bearing

– Examine clutch housing, replace

if necessary

– Examine rubber insert and

clamp, install in new clutch

housing if necessary, b 9.1

4 -point antivibration system

– Examine both rubber buffers,

push onto new clutch housing, if

necessary, b 9.2

– Examine clutch, replace if

necessary, b 4.2

5904RA017 TG

1

2

3

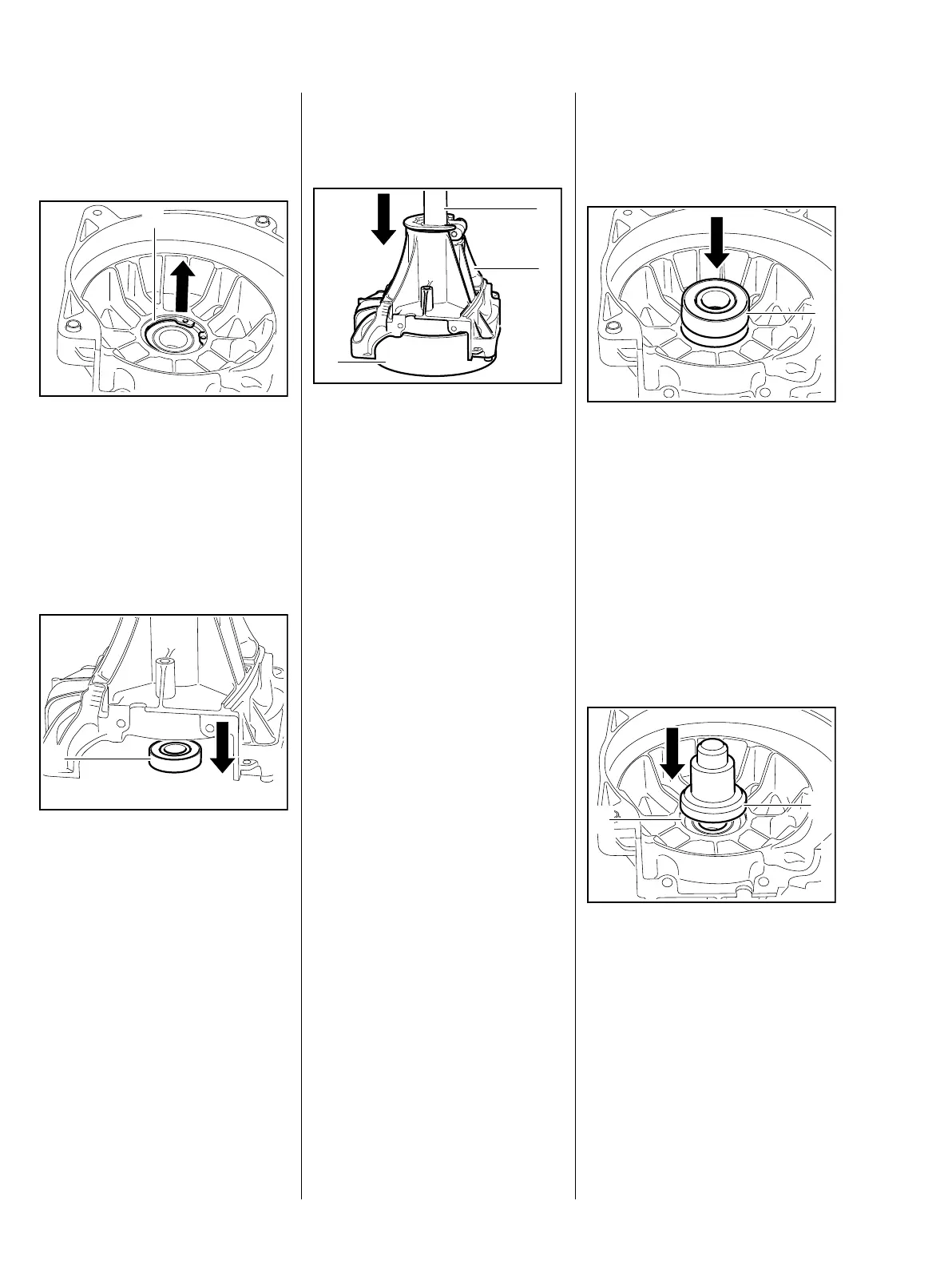

Installation

Rubber insert or rubber buffers

must be removed.

– Heat the area around the bearing

seat to approx. 120 °C (250 °F)

: Press the ball bearing (1) home

as far as possible

The ball bearing must be fitted

rapidly, as it absorbs heat and

expands.

If it is impossible to heat the clutch

housing, the ball bearing must be

pressed in cold.

: Press the new ball bearing (1)

fully home with press arbor (2)

1118 893 7200

5904RA018 TG

1

5904RA019 TG

1

2

Loading...

Loading...