•

Ifthepressuredrops,theleak

mustbelocatedandthefaulty

partreplaced.

Note:Tolocatetheleak,coatthe

suspectareawithoilandpressuri-

zethecrankcaseagain.Bubbles

willappearattheoil-coatedareaif

aleakexists.

-Thencarryoutvacuumtest,

see4.2.3.

-Openventscrewanddisconnect

hosewhentestiscomplete.

-Removetestflange.

-Loosenthemufflerscrews.

-Drawoutthesealingplateand

tightenthemufflerscrewswith

9.5Nm.

-Fitouterscrewofmufflerand

tightenwith9.5Nm.

-Installcarburetor,see8.2.2.

Oilsealstendtofailwhensub-

jectedtoavacuum,i.e.thesealing

lipliftsawayfromthecrankshaft

duringthepiston’sinductionstroke

becausethereisnointernalcoun-

terpressure.

Faultsofthiskindcanbedetected

withtheaidofavacuumpump.

Thepreparationsarethesameas

forthepressuretest,see4.2.2.

•

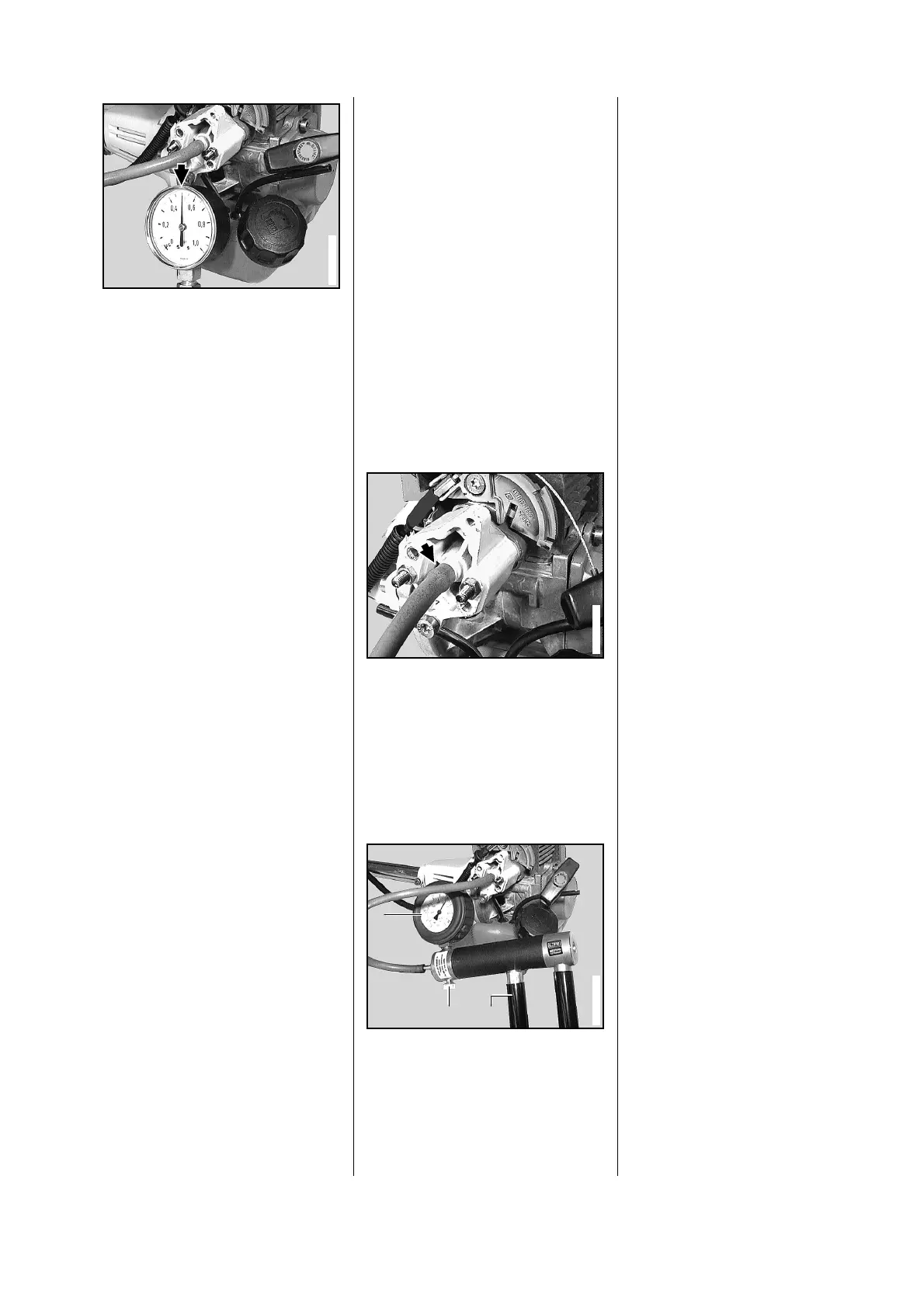

Connectsuctionhoseofvacuum

pump00008503501tonippleof

testflange.

•

Closeventscrew(1)onpump

cylinder.

•

Actuatelever(2)untilpressure

gauge(3)indicatesavacuumof

0.5bar.

Note:Theoilsealsareingood

conditioniftheindicatedvacuum

ismaintainedorifthepressure

risestonomorethan0.3bar

within20seconds.

Theoilsealsmustbereplacedif

thepressureinthecrankcasecon-

tinuestorise.

-Openventscrewanddisconnect

hosewhentestiscomplete.

-Removetestflange.

-Loosenmufflerscrews.

-Removesealingplateand

tightenscrewstoatorqueof9.5

Nm.

-Fitouterscrewinmufflerand

tightentoatorqueof9.5Nm.

-Installcarburetor,see8.2.2.

392RA021 VA

392RA020 VA

33

11

22

392RA022 VA

4.2.3 Vacuumtest

13

Loading...

Loading...